Method for calculating specification of eight-anchor-bolt rigid tower base plate for power transmission tower

An anchor bolt and calculation method technology, which is applied in calculation, electrical digital data processing, special data processing application and other directions, can solve the problems of inconsistent calculation results, high cost and time-consuming real-type test and test, and achieve reasonable calculation results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but the embodiments should not be construed as limiting the present invention, but only as examples, and the advantages of the present invention will become clearer and easier to understand.

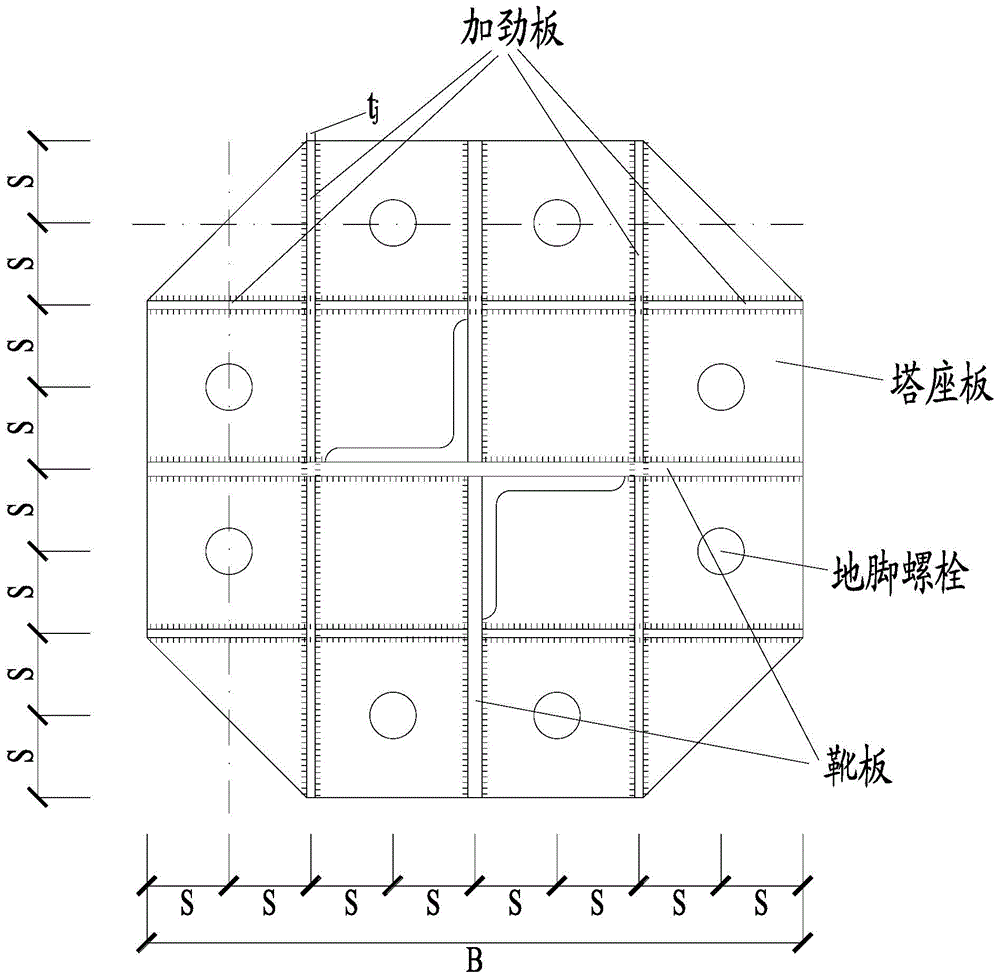

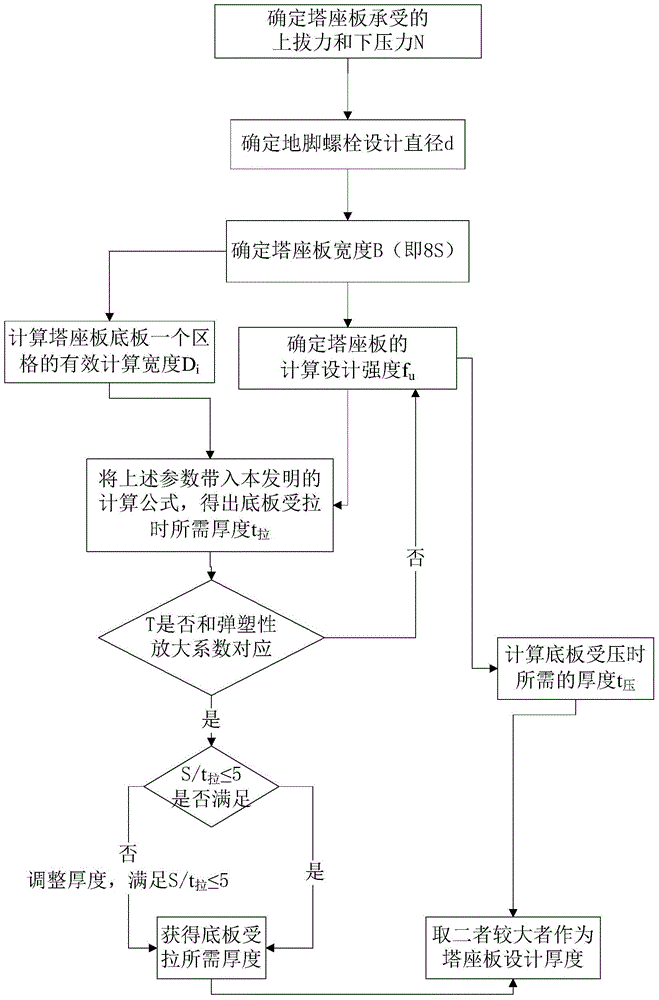

[0051] As shown in the attached figure, the calculation method for the specifications of the rigid tower seat plate with eight anchor bolts for the transmission tower is carried out according to the following steps:

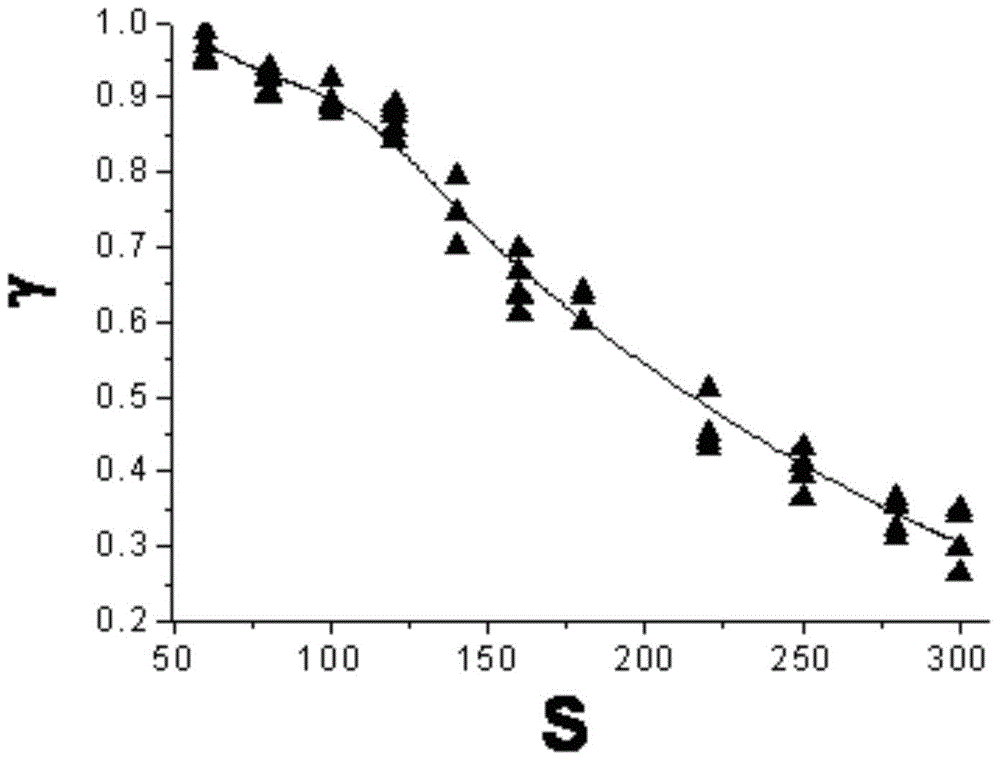

[0052] Step 1. Determine the uplift force and downforce N of the tower base plate through the calculation of the iron tower, and use them as the external input conditions for the calculation of the tower base plate. The uplift force is decomposed into the analysis of the uplift force of each anchor bolt. The pull-out force of each anchor bolt is T; and through the pull-out force T and the down force N, determine the design diameter d of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com