Label and method for manufacturing same

A manufacturing method and labeling technology, which is applied to chemical instruments and methods, paper/cardboard layered products, laminating devices, etc., can solve the problems of easy glue overflow and automatic labeling, so as to save labor costs and avoid manual labeling target effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

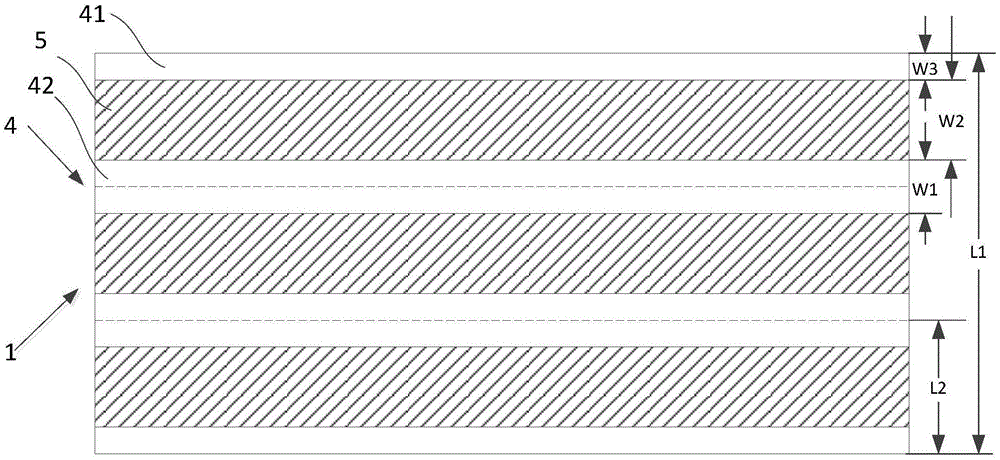

[0027] The specific implementation of the present invention will be described in more detail below in conjunction with the schematic diagram. According to the following description and claims, the advantages and features of the present invention will be clearer. It should be noted that the drawings are in a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

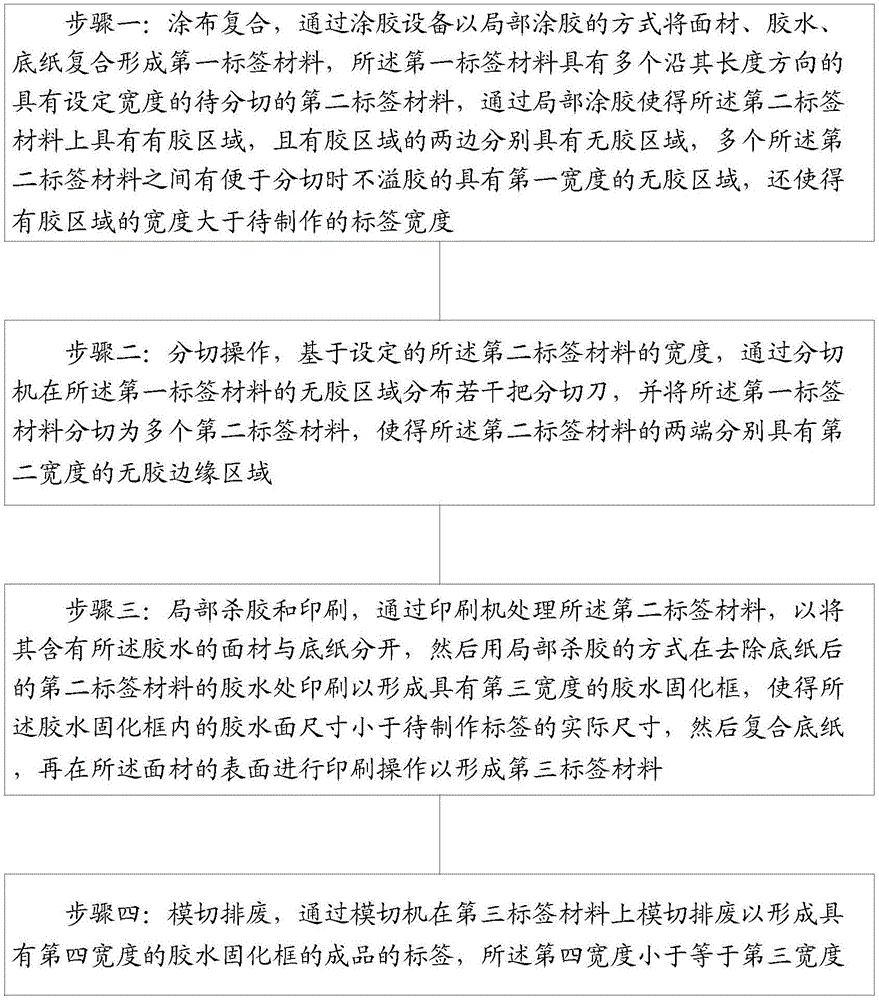

[0028] Such as Figure 1~8 As shown, the embodiment of the present invention provides a method for making a label, including:

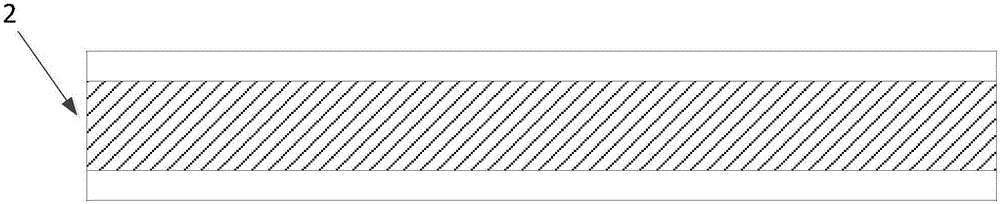

[0029] Step 1: Coating and compounding. The surface material, glue, and bottom paper are compounded into a first label material 1 with an initial width L1 through a glue application device in a partial gluing manner. The first label material 1 has a plurality of The second label material 2 to be slit with a set width L2 in the length direction is partially glued so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com