Low-voltage welding transformer and operation method thereof

A technology for welding transformers and operation methods, applied in the field of transformers, can solve the problems of long operation time, not easy to control, easy to fuse wires, etc., and achieves the effects of good heat dissipation and strong short-circuit resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

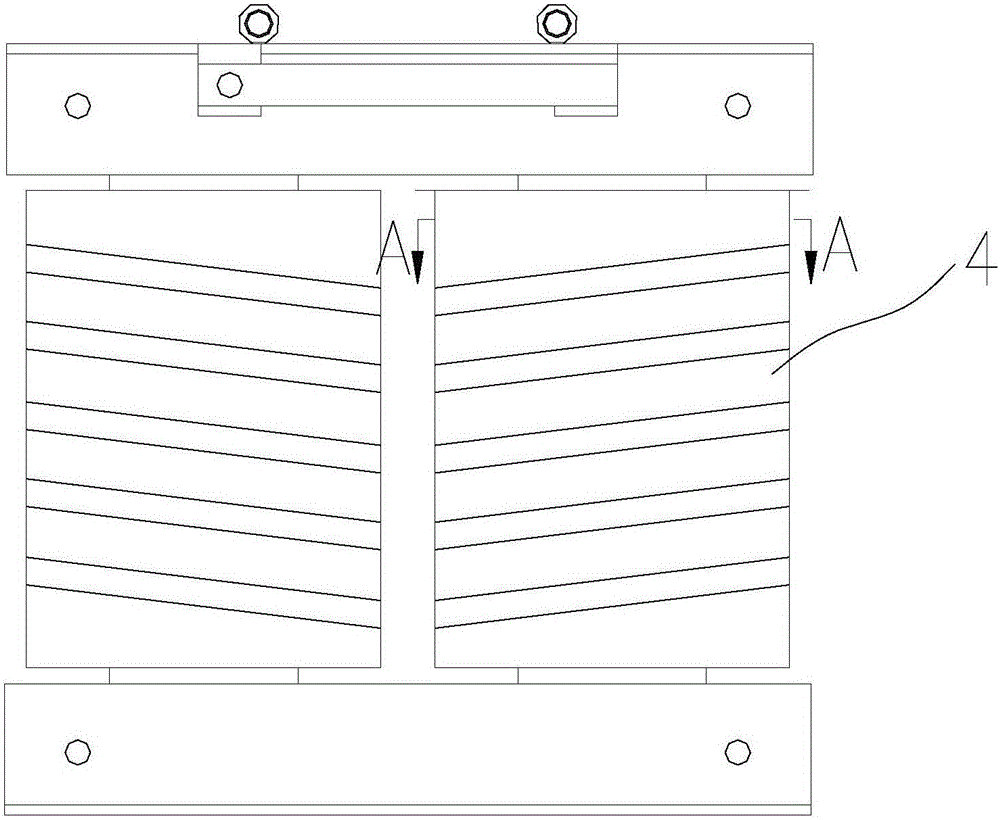

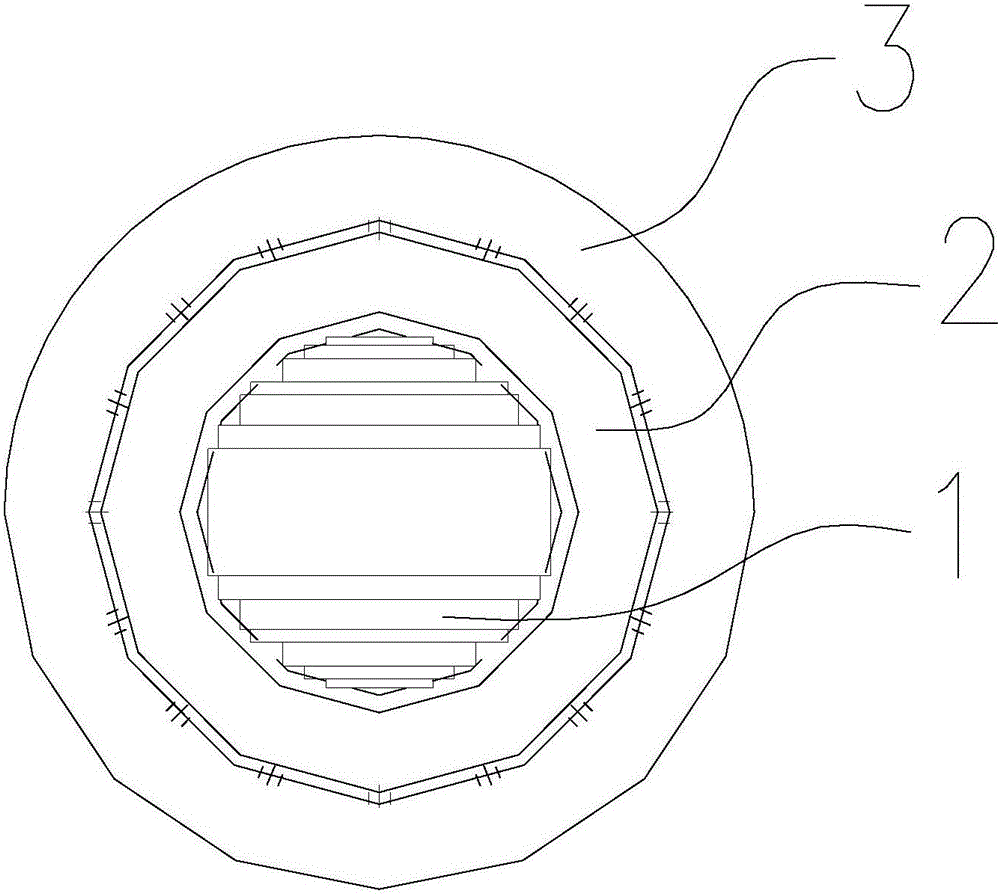

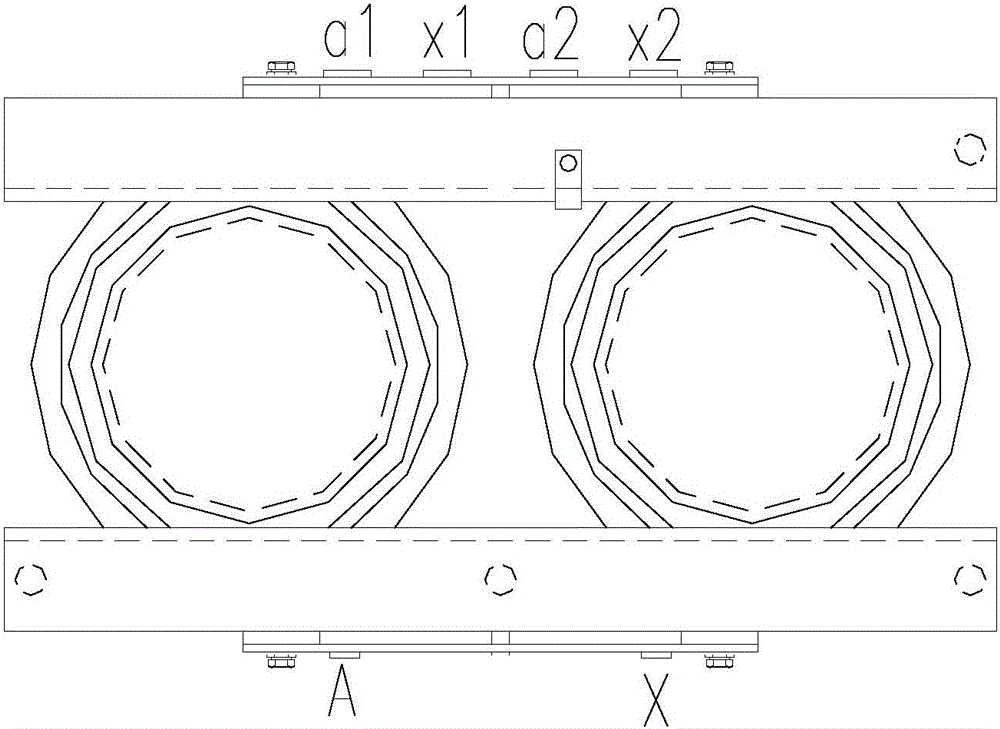

[0025] Such as Figure 1 to Figure 4 As shown, the present invention provides a low-voltage welding transformer, including: two sets of transformer winding assemblies with the same structure, the transformer winding assembly includes: an iron core 1, and the iron core 1 is provided with a primary winding 2 and a secondary Winding 3; the primary winding 2 in the two sets of transformer winding assemblies is connected in series (the two input ends of the secondary winding 2 are A and X respectively, which are suitable for accessing single-phase 380V AC voltage), and are respectively connected to the corresponding secondary windings in the transformer windings. The windings 3 are coupled; the two secondary windings 3 respectively lead out two output ends; and the two output ends respectively led out of the two secondary windings 3 are connected correspondingly to form a series output or a parallel output of the two secondary windings 3 .

[0026] The iron core 1 is located in the...

Embodiment 2

[0036] Such as Figure 1 to Figure 4 As shown, on the basis of Embodiment 1, the present invention also provides a method for operating a low-voltage welding transformer.

[0037] Wherein, the low-voltage welding transformer includes: two sets of transformer winding assemblies with the same structure, and the transformer winding assemblies include: an iron core 1, and the iron core 1 is provided with a primary winding 2 and a secondary winding 3; two sets of transformer winding assemblies The primary windings 2 in the winding assembly are connected in series, and are respectively coupled with the corresponding secondary windings 3 in the transformer winding; the two secondary windings 3 respectively lead to two output terminals; the operation method includes: leading the two secondary windings 3 respectively to The two output ends of the two outputs are connected correspondingly to form a series output or a parallel output of the secondary winding 3 .

[0038] Moreover, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com