Novel winding staggered type distribution transformer

A distribution transformer, staggered technology, applied in the field of distribution transformers, can solve problems such as rising costs, inability of transformer oil to flow, and increasing creepage distance along the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0113] Example 1, S13—400 / 10±2×0.25% / 0.4

[0114] National standard: load loss Pk=4200W

[0115] No-load loss P0=410W

[0116] No-load current percentage I0%=0.8%

[0117] Impedance voltage percentage Uk%=4%

[0118] Total loss P=4930 W

[0119] 1. New transformer S13—400 / 10±2×0.25% / 0.4

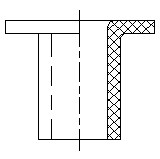

[0120] Design scheme: the cross section of the core winding is oblong

[0121] The core length and short axis ratio is 1:1.49, the small circle diameter of the core is Φ155mm, the main stage of the core is thickened by 33mm, and the cross-sectional area of the core is 280.006cm 2 . Core flux density Bm=1.546T, M 0 =255mm, Hw=400mm.

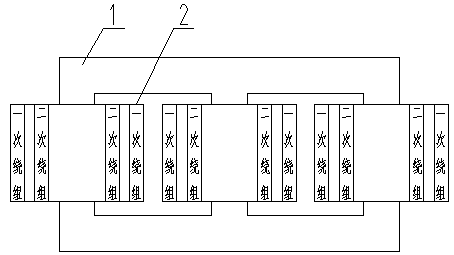

[0122] Winding structure: staggered, six magnetic balance groups.

[0123] High-voltage winding: It is a disc winding with a flattened structure, and the number of turns is 630 turns, 600 turns, and 570 turns. Wire gauge ZB—0.32.12×4. Each double magnetic balance group has 15 turns / layer, a total of 15 layers.

[0124] Low-voltage winding: spiral pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com