Spiral plate-type winding

A spiral plate type and spiral type technology, applied in the direction of transformer/inductor coil/winding/connection, electrical components, transformer/inductor parts, etc., can solve the problems of area reduction, poor manufacturing process, etc., and improve the filling factor , strong short-circuit resistance and strong overload capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

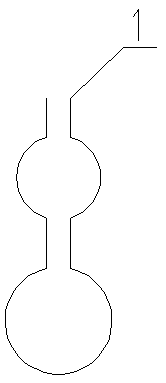

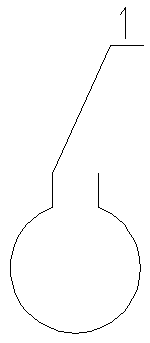

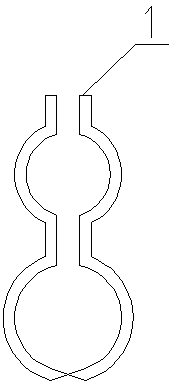

[0040] Example 1. For the low-voltage winding of S13—400 / 10±2×0.25% / 0.4, select spiral plate winding without end insulation, such as Figure 7 .

[0041] Because of the six magnetic balance groups, there are six sets of windings.

[0042] Low-voltage winding: spiral plate winding with a flattened structure, with an oblong cross section.

[0043] The number of turns is 24 turns.

[0044] Copper plate 5×41.

[0045] Two single magnetic balance groups with 4 turns.

[0046] Two double magnetic balance groups with 8 turns.

[0047] The inner diameter of the short shaft is 165mm.

[0048] The outer diameter of the short shaft is 247mm.

[0049] The inner diameter of the major axis = the inner diameter of the minor axis + the distance between the straight lines = 165 + 40 × 2 = 245 mm.

[0050] Long shaft outer diameter = short shaft outer diameter + straight line distance = 241 + 40 × 2 = 321mm.

[0051] Winding height = 27 mm.

[0052] Winding height=27mm for impedance voltage calculation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com