500kV radial split transformer

A technology for splitting transformers and transformers is applied in the field of transformers to achieve the effects of strong short-circuit resistance, safe and reliable product performance, and simple product structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

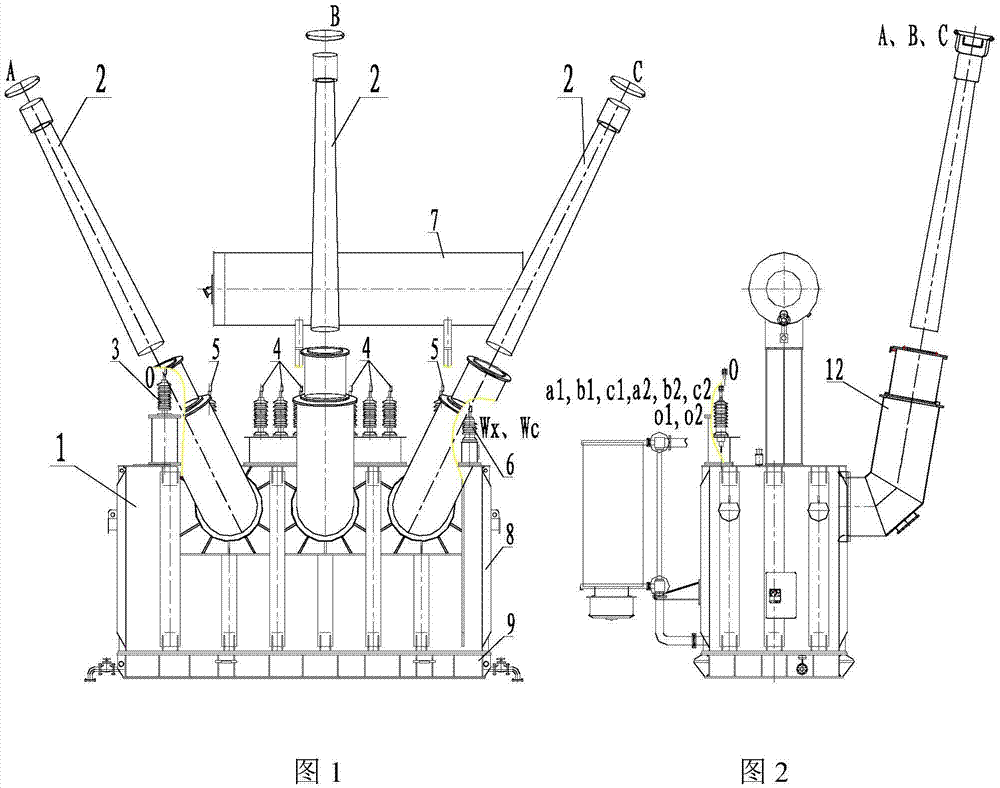

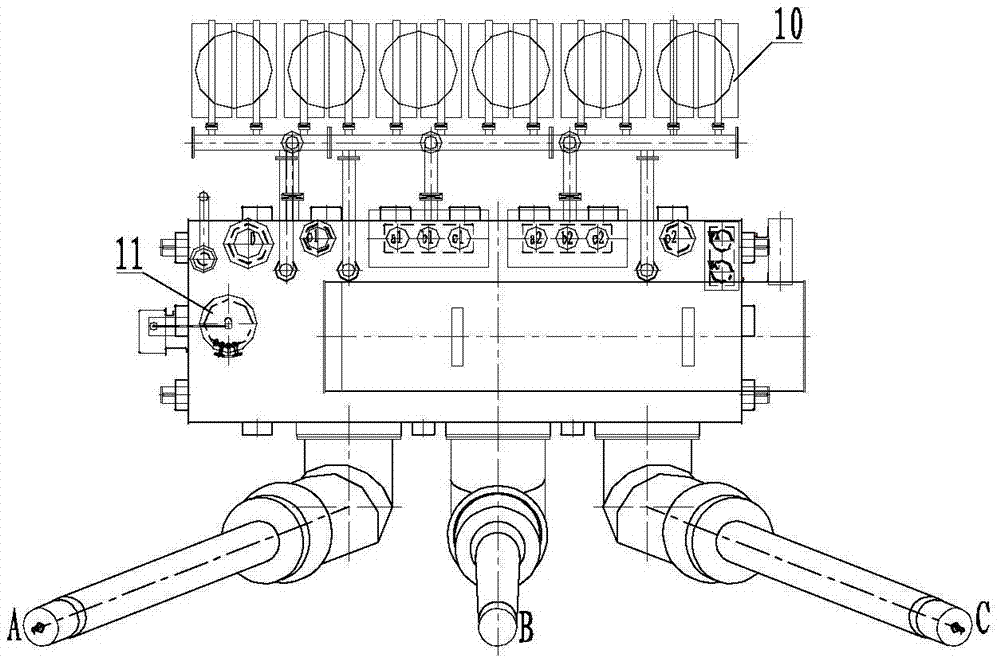

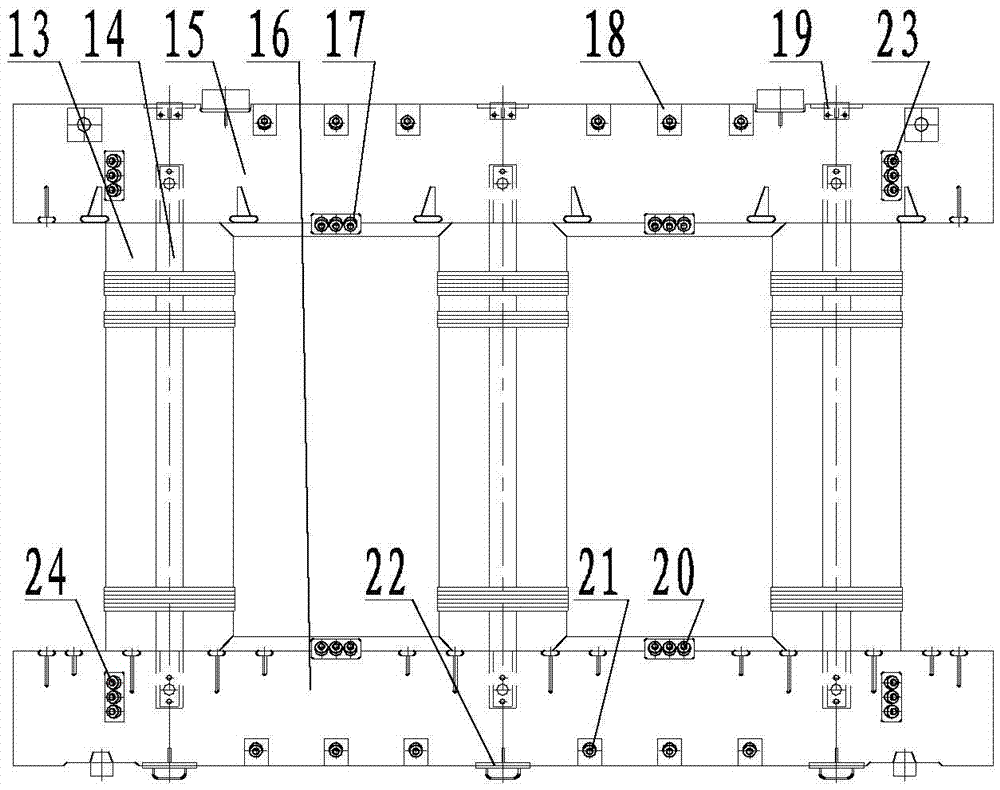

[0030] Such as Figure 1~3 As shown, a 500kV radial split transformer of the present invention has an oil tank main body formed by an upper oil tank 8 and a lower oil tank 9, a high-voltage bushing 2, a low-voltage bushing 4, an oil storage tank 7, a radiator 10, a load distribution Connect the switch 11 and the high-voltage outlet box 12. The inside of the transformer body adopts an iron core-voltage stabilizing coil WV-low voltage coil I LV1-voltage regulating coil TV-high voltage coil GY-low voltage coil II LVII arrangement structure, iron core Set in the upper fuel tank 8 and the lower fuel tank 9, each column iron core is covered with a voltage stabilizing coil WV, a low voltage coil I LVI, a voltage regulating coil TV, a high voltage coil GY and a low voltage coil II LVII. , the radial direction of the outer winding comes out, and the rest of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com