Distribution transformer with staggered windings

A distribution transformer, interlaced technology, applied in the field of distribution transformers, can solve the problem of low pass rate of sudden short-circuit test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0066] Example 1, S13—400 / 10±2×0.25% / 0.4

[0067] National standard: load loss Pk=4200W

[0068] No-load loss P0=410W

[0069] No-load current percentage I0%=0.8%

[0070] Impedance voltage percentage Uk%=4%

[0071] Total loss P=4930 W

[0072] 1. New transformer S13—400 / 10±2×0.25% / 0.4

[0073] Design scheme: the cross section of the core winding is oblong

[0074] The core length and short axis ratio is 1:1.49, the small circle diameter of the core is Φ155mm, the main stage of the core is thickened by 33mm, and the cross-sectional area of the core is 280.006cm 2 . Core flux density Bm=1.546T, M0=255mm, Hw=400mm.

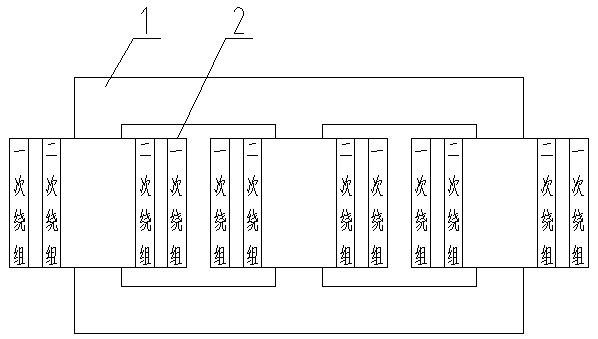

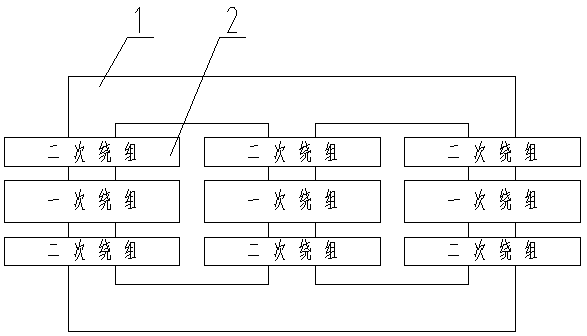

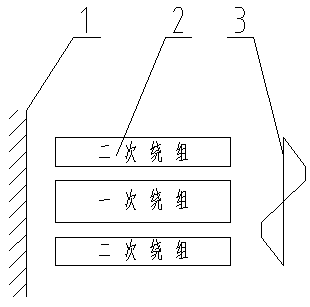

[0075] Winding structure: staggered, six magnetic balance groups.

[0076] High-voltage winding: It is a disc winding with a flattened structure, and the number of turns is 630 turns, 600 turns, and 570 turns. Wire gauge ZB—0.32.12×4. Each double magnetic balance group has 15 turns / layer, a total of 15 layers.

[0077] Low-voltage winding: spiral plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com