Halbach array permanent magnet DC brushless motor

A brushless motor, permanent magnet DC technology, applied in electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of low utilization rate of magnetic energy of stator winding, unavailability of electromagnetic field, and low utilization rate of magnetic energy of stator coil. , to achieve the effect of reducing cost and weight, simple structure and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

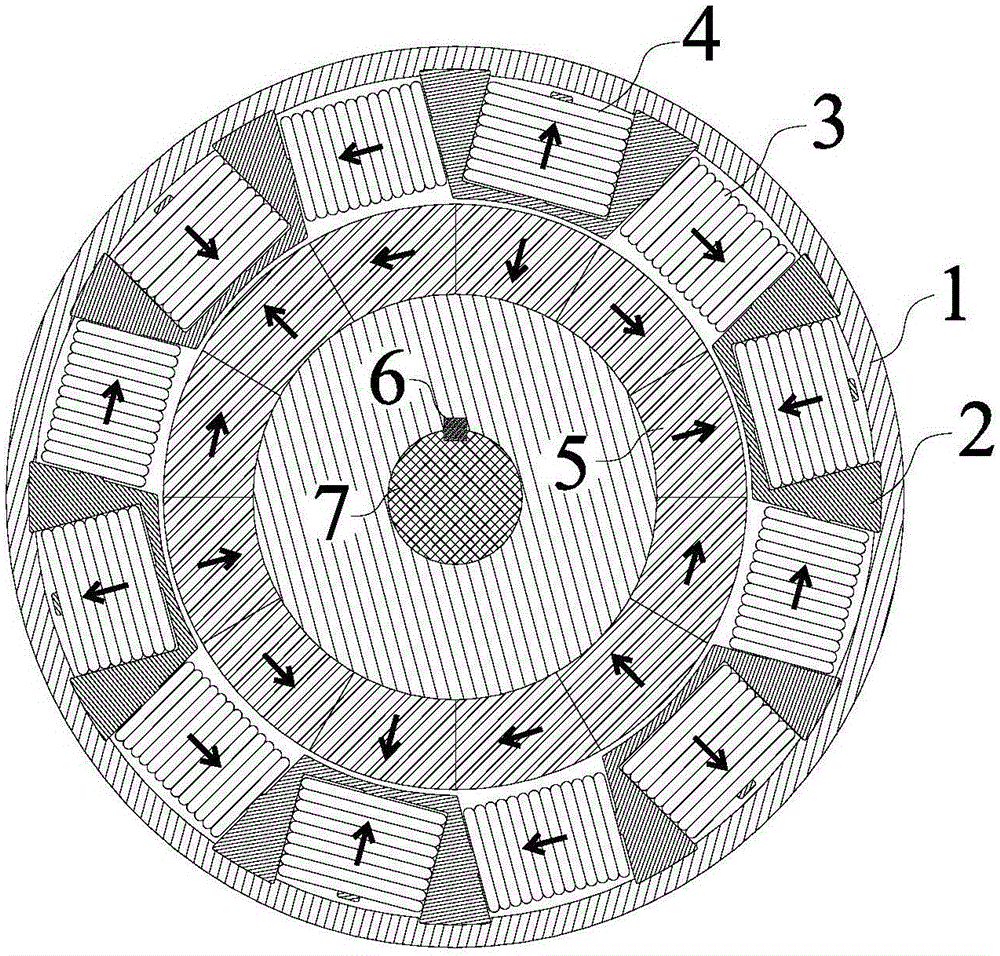

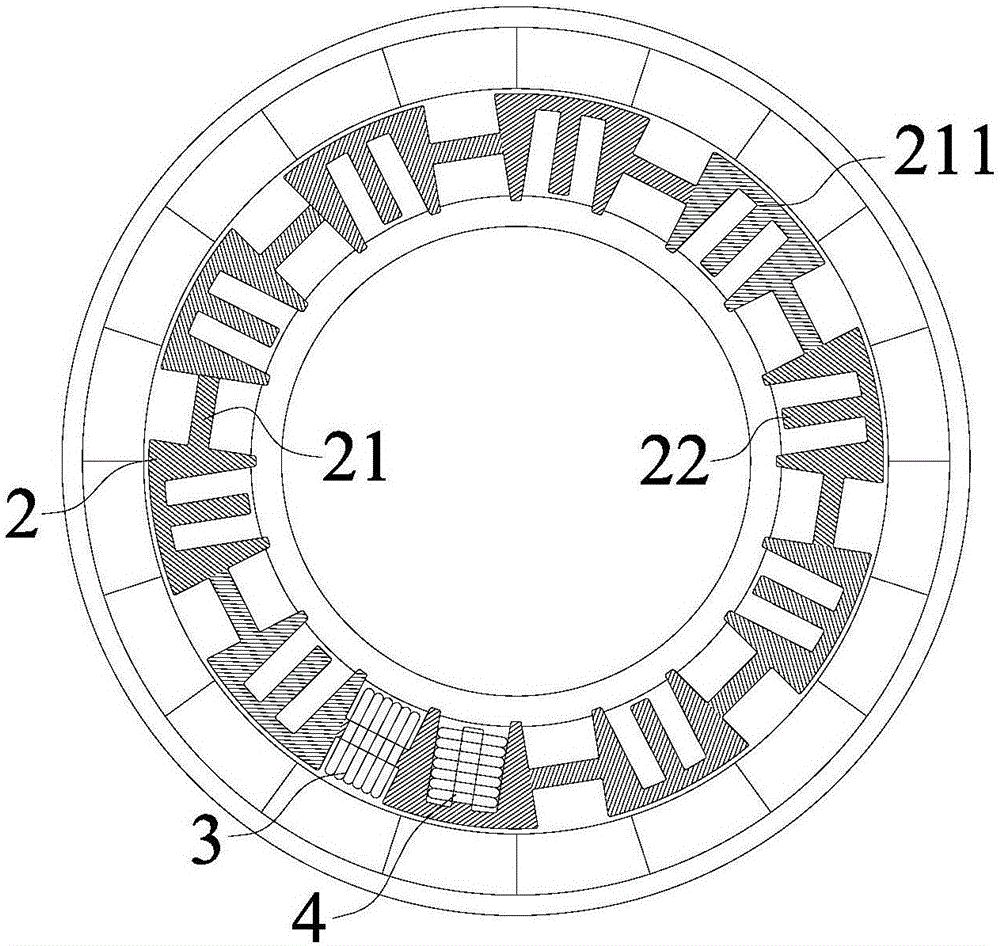

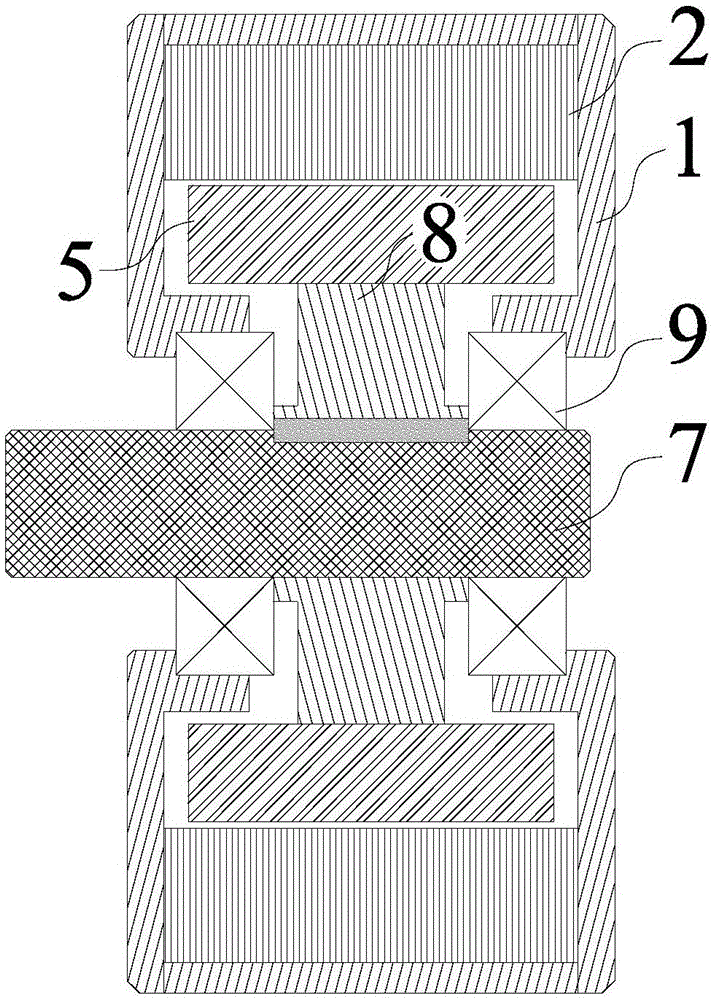

[0027] like figure 1 Shown in -7, the Halbach array type permanent magnet brushless DC motor of the present invention includes a casing 1, a stator fixed in the casing, a rotor connected to the casing bearing and a commutation circuit;

[0028] Wherein, the rotor includes an annular turntable body 8 and 4n tile-shaped permanent magnet blocks 5 closely arranged along the circumferential direction and inlaid on the turntable body, n is an integer and greater than or equal to 1, and the permanent magnet blocks include radially charged The magnetic permanent magnet block and the tangentially magnetized permanent magnet block, the radially charged permanent magnet block and the tangentially magnetized permanent magnet block a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com