Pre-drilling wet-type plating metal substrate and manufacturing method therefor

A manufacturing method and pre-drilling technology, which can be used in circuit substrate materials, printed circuit manufacturing, and structural connection of printed circuits, etc., can solve the problems of cumbersome manufacturing of flexible circuit boards, unfavorable microporation, and large thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

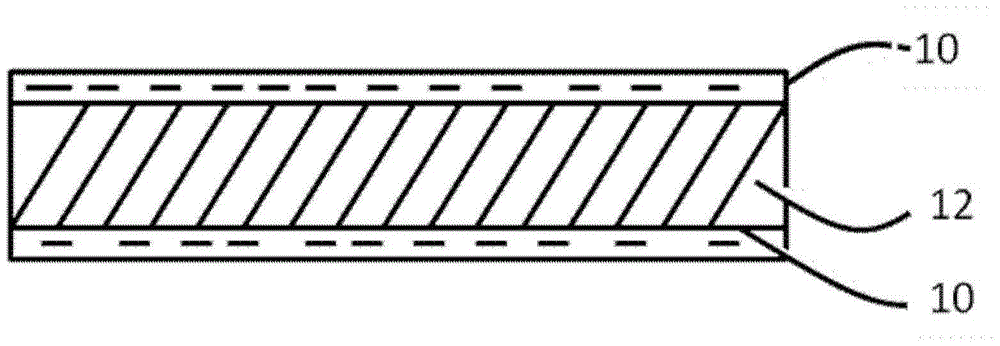

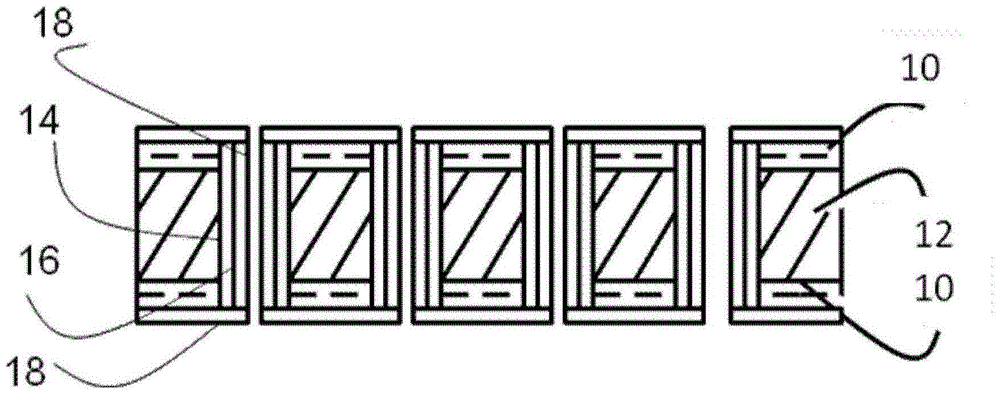

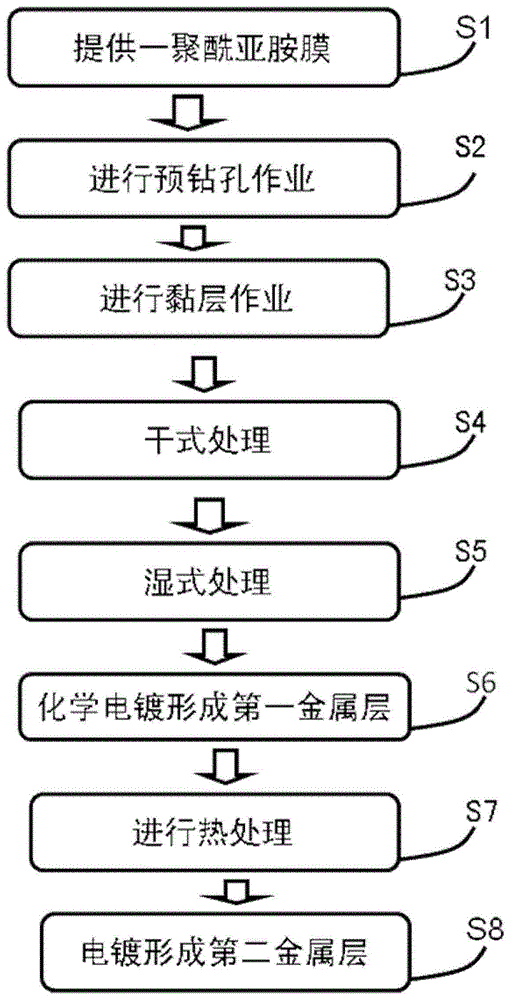

[0029] For the manufacturing method of the pre-drilled wet electroplated metal substrate of the present invention, please refer to image 3 and Figure 4 As shown, it includes providing a polyimide film 20 (Polyimidefilm) (S1). In this embodiment, its monomer composition and preparation method are not particularly limited, and can be carried out by common techniques in the art. The thickness It can be 7-50 microns (μm).

[0030] Please refer to image 3 As shown, step S1: provide a polyimide film 10, step S2: please refer to Figure 5 As shown, the polyimide film (Polyimide film) 10 is pre-drilled to form a plurality of through holes 22 on the surface of the polyimide film 20 .

[0031] Step S3: Perform a sticky layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap