Solenoid valve with improved opening and closing characteristics

A technology of solenoid valves and closing elements, which is applied in the field of solenoid valves, can solve problems such as poor closing time, and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

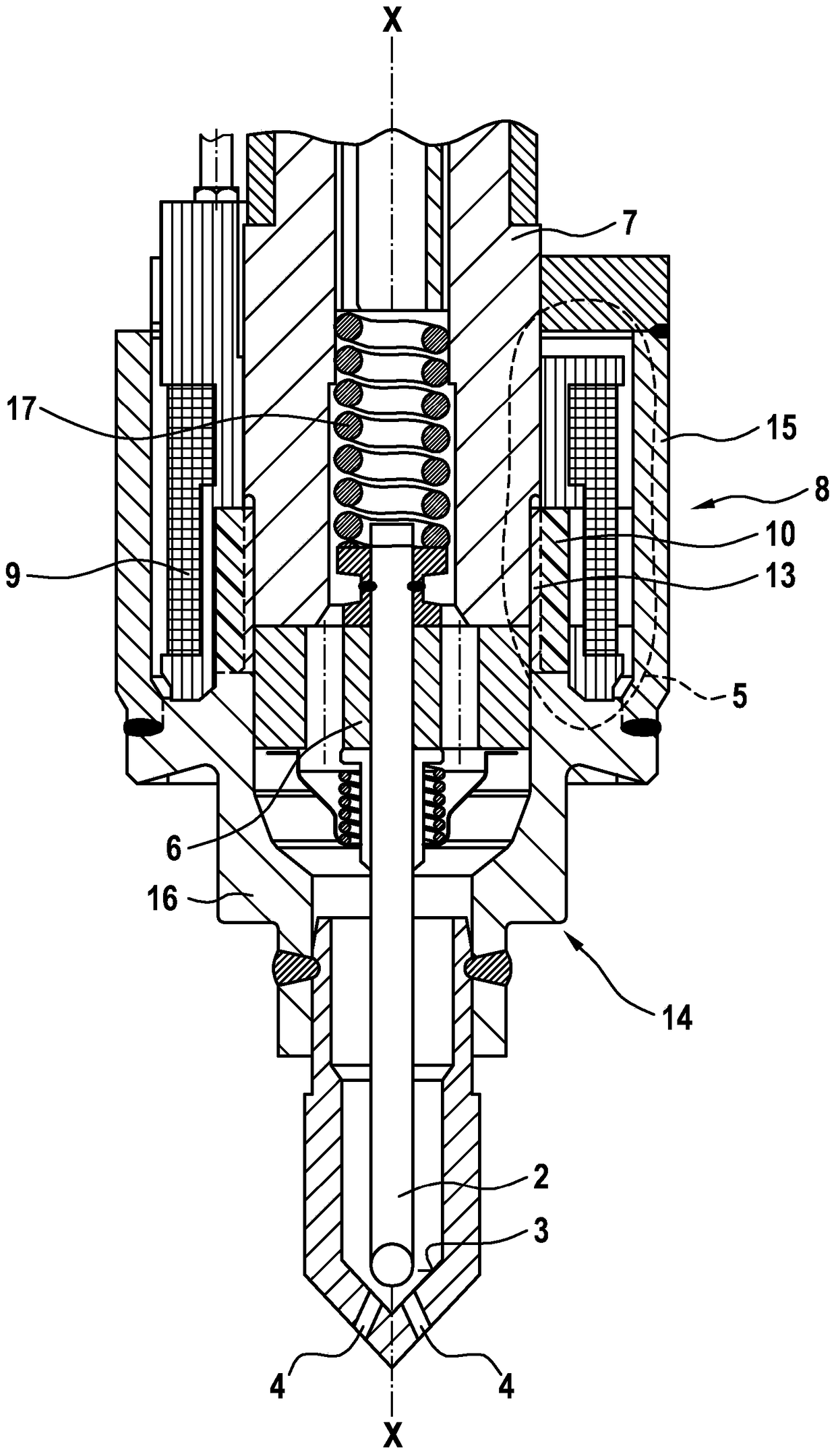

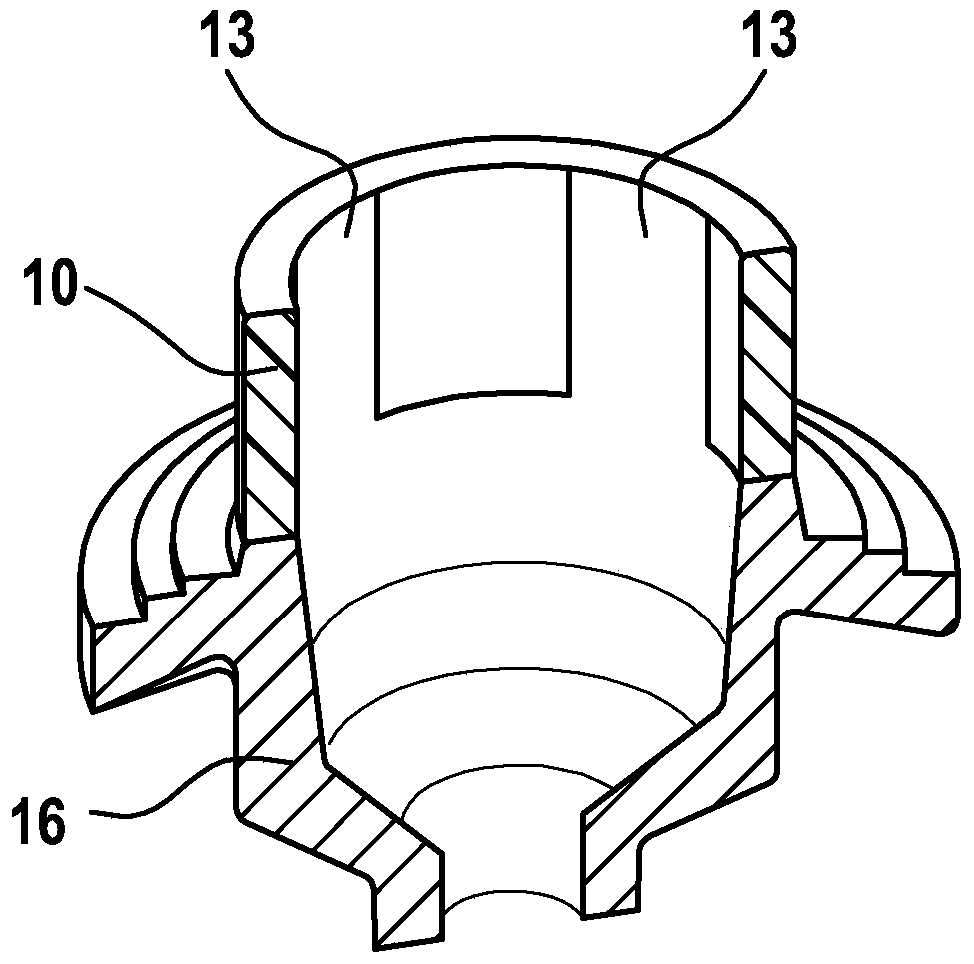

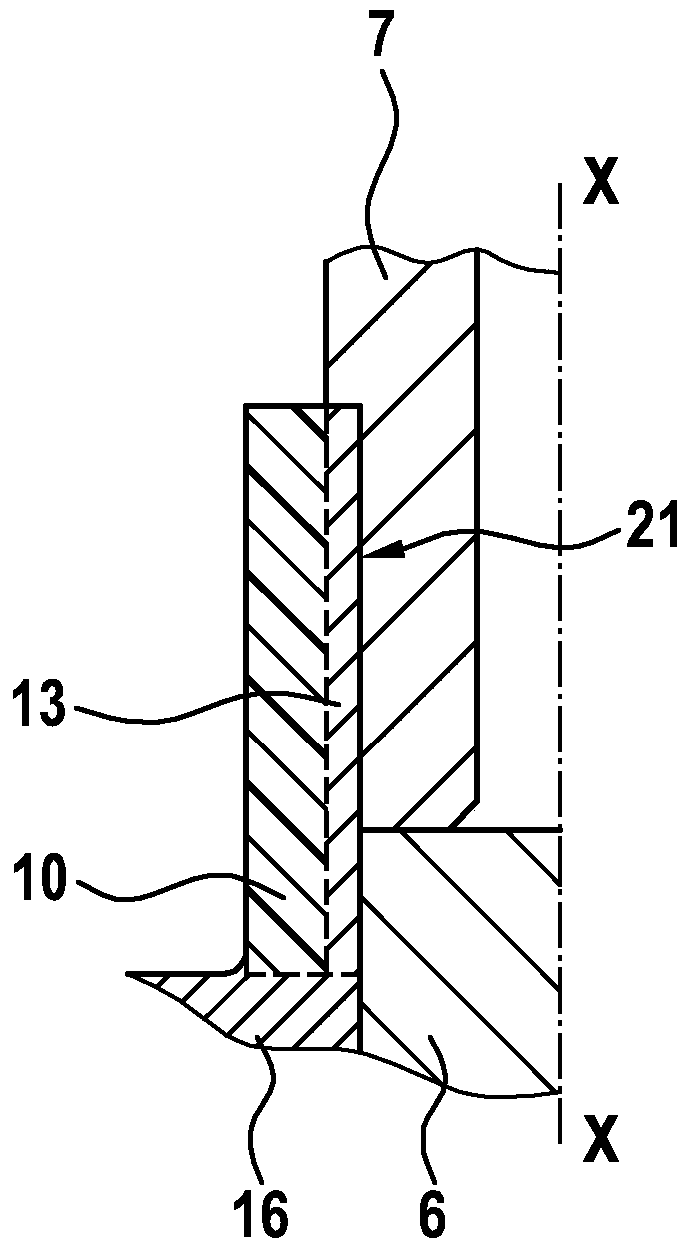

[0016] Refer to the attached Figures 1 to 3 The solenoid valve 1 for controlling fluid according to the first embodiment will be described in detail.

[0017] as from figure 1 Obviously, the solenoid valve 1 comprises a closing element 2 in the form of a valve needle, which has a ball on the closing side, which releases and closes the outlet opening 4 on the valve seat 3 .

[0018] Furthermore, the solenoid valve 1 includes a magnetic circuit 5 with an armature 6 , an inner pole 7 and a yoke 8 . In this exemplary embodiment, the magnetic yoke 8 is part of the housing 14 of the solenoid valve, the housing 14 being constructed in multiple parts. Here, the two housing parts 15 , 16 are part of the magnetic circuit 5 .

[0019] Furthermore, solenoid valve 1 includes a coil 9 which attracts armature 6 when energized. After the coil 9 has ended the current flow, the restoring element 17 returns the armature 6 to the starting position again. here, figure 1 The open state of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com