A finishing process for large-size single crystals and a preparation process for large-size single crystals

A large-scale, single-crystal technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of prolonging the closing time, reducing the utilization rate of effective production hours, increasing the risk of single crystal breakage, etc. The effect of increasing single crystal production capacity, improving single crystal closing time, and ensuring the quality of property rights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

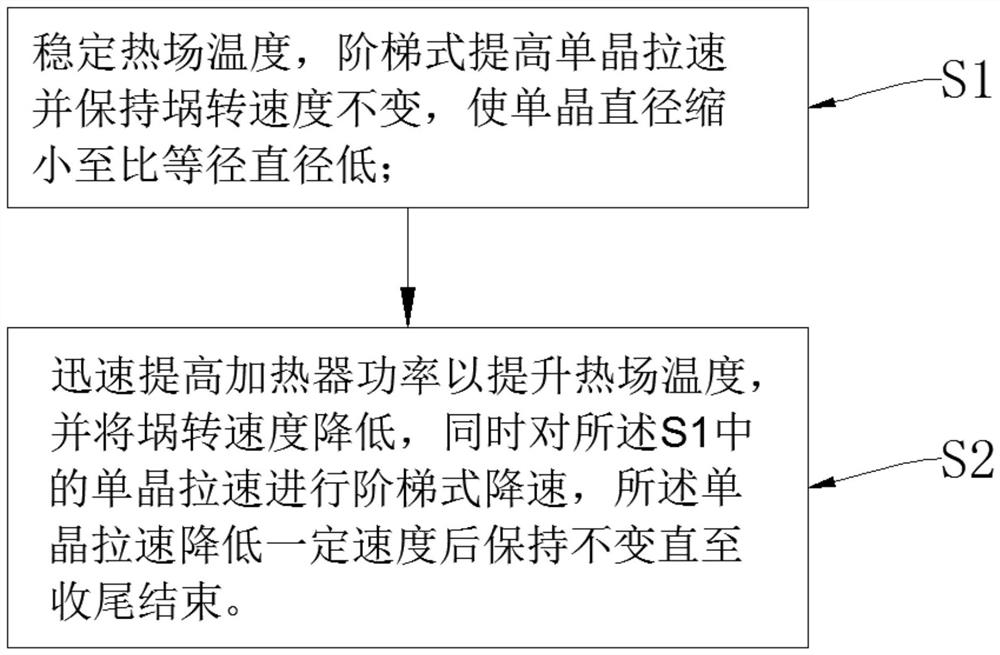

Method used

Image

Examples

Embodiment 1

[0030] The single crystal diameter is 240m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0031] The first stage: when the equal diameter is completed, the thermal field temperature is 1231sp, the single crystal pulling speed is 83mm / hr, the heater power is 67kW, and the crucible rotation speed is 10r / min.

[0032] In this stage, the temperature of the stable thermal field remains unchanged at 1231sp, the heater power remains unchanged at 67kW and the crucible rotation speed is kept at 10r / min; at the same time, the single crystal pulling speed is increased, and the single crystal pulling speed is slowly increased within 0.3h. Speed, then quickly increase the single crystal pulling speed to 90mm / hr within 0.6h, then stabilize the single crystal pulling speed for 0.1h, and finally complete the finishing work of the first stage within 1h.

[0033] At the end of the first stage, the diameter of the single crystal ends up being 110mm and the length of the end is ...

Embodiment 2

[0038] The single crystal diameter is 280m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0039] The first stage: when the equal diameter is completed, the temperature of the thermal field is 1219sp, the single crystal pulling speed is 80mm / hr, the heater power is 64.5kW, and the crucible rotation speed is 10r / min.

[0040] In this stage, the temperature of the stable thermal field remains unchanged at 1219sp, and the power of the heater remains unchanged at 64.5kW at this time, and the rotation speed of the crucible is kept at 10r / min; at the same time, the pulling speed of the single crystal is increased, and the single crystal is slowly raised within 0.3h Pulling speed, quickly increase the single crystal pulling speed to 95mm / hr within 0.5h, then stabilize the single crystal pulling speed for 0.1h, and finally complete the finishing work of the first stage within 0.9h.

[0041] At the end of the first stage, the diameter of the single crystal ends up bein...

Embodiment 3

[0046] The single crystal diameter is 310m, and the Czochralski single crystal furnace is Jingsheng 105s.

[0047] The first stage: when the equal diameter is completed, the thermal field temperature is 1205sp, the single crystal pulling speed is 77mm / hr, the heater power is 63kW, and the crucible rotation speed is 10r / min.

[0048] In this stage, the temperature of the stable thermal field remains unchanged at 1205sp, the power of the heater remains unchanged at 63kW and the crucible rotation speed is kept at 10r / min; at the same time, the single crystal pulling speed is increased, and the single crystal pulling speed is slowly increased within 0.3h. Speed, then quickly increase the single crystal pulling speed to 98mm / hr within 0.4h, and then stabilize the single crystal pulling speed for 0.3h, and finally complete the finishing work of the first stage within 1h.

[0049] At the end of the first stage, the diameter of the single crystal ends up being 150mm and the length of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com