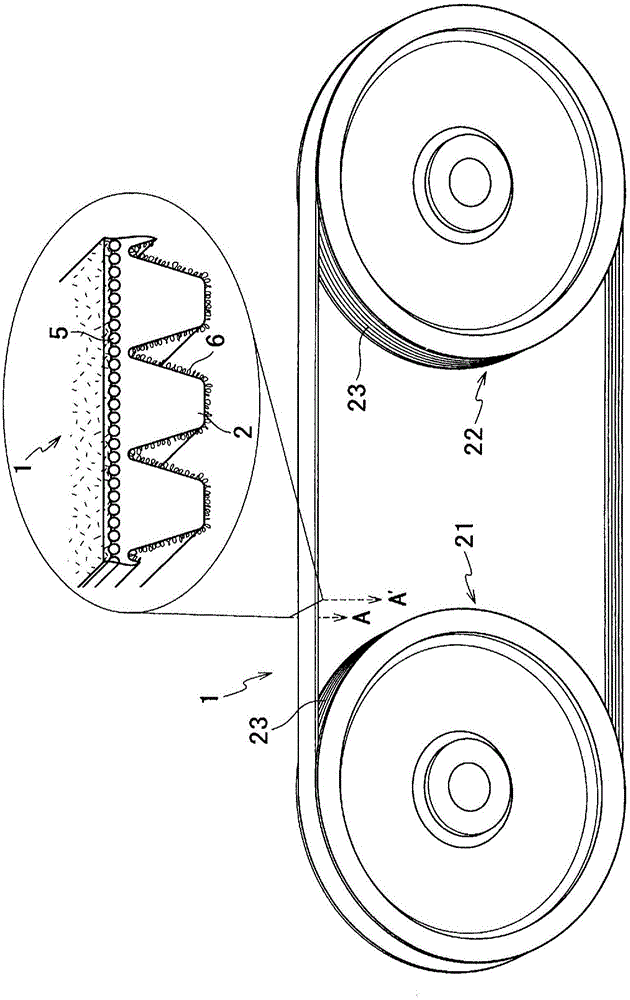

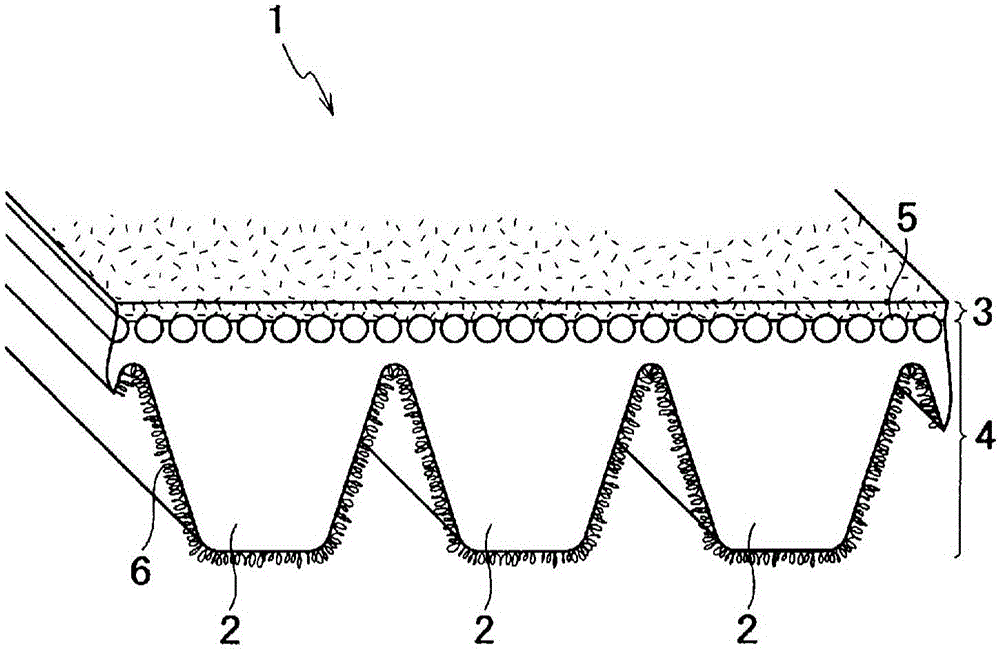

V-ribbed belt

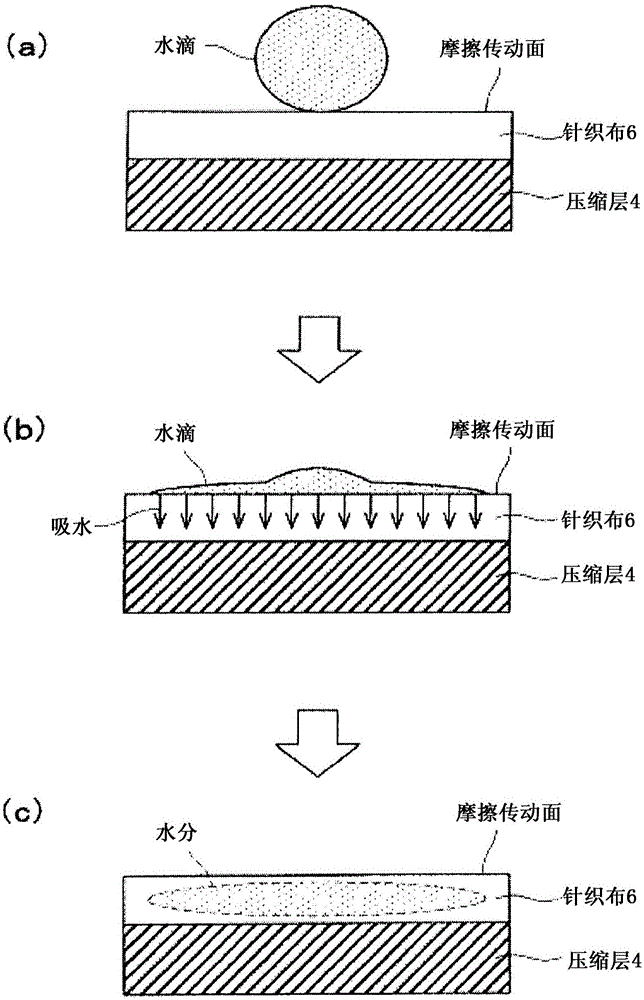

A technology of multi-ribbed belt and extension layer, applied in the direction of V-belt, belt/chain/gear, mechanical equipment, etc., can solve the problems of increased friction coefficient of friction transmission surface, poor noise resistance, reduced friction coefficient, etc. Effects of small friction coefficient differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0085]

[0086] As shown in Table 1, as an example of the V-ribbed belt 1, the following knitted fabric is prepared: cotton yarn is used as the cellulose-based natural spun yarn of the knitted fabric 6, the weaving ratio is 50 to 95% by mass, and PTT / PET composite yarn is used as the knitted fabric (embodiment 1~3,5,6) of polyester composite yarn; Use PET / PU core-spun yarn as the knitted fabric (embodiment 4,7) of polyester composite yarn; In the knitted fabric 6 of Example 6, the knitted fabric (Example 8) containing and adhering a nonionic surfactant polyethylene glycol type nonionic surfactant as a hydrophilizing agent; Knitted fabrics of polyether-modified silicone softeners and polyester softeners as softeners (Examples 9 and 10). The knitted fabric structures of Examples 1 to 4 are single-layer, and the knitted fabric structures of Examples 5 to 10 are multi-layered, and a large amount of cotton yarn is arranged in the layer on the friction transmission surface side ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com