Polarizing plate and liquid crystal display device including the polarizing plate

A liquid crystal display device, polarizing plate technology, applied in optics, optical elements, polarizing elements, etc., can solve the problems of image quality deterioration and manufacturing cost increase, and achieve the effect of ensuring viewing angle, good price competitiveness, and maintaining image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

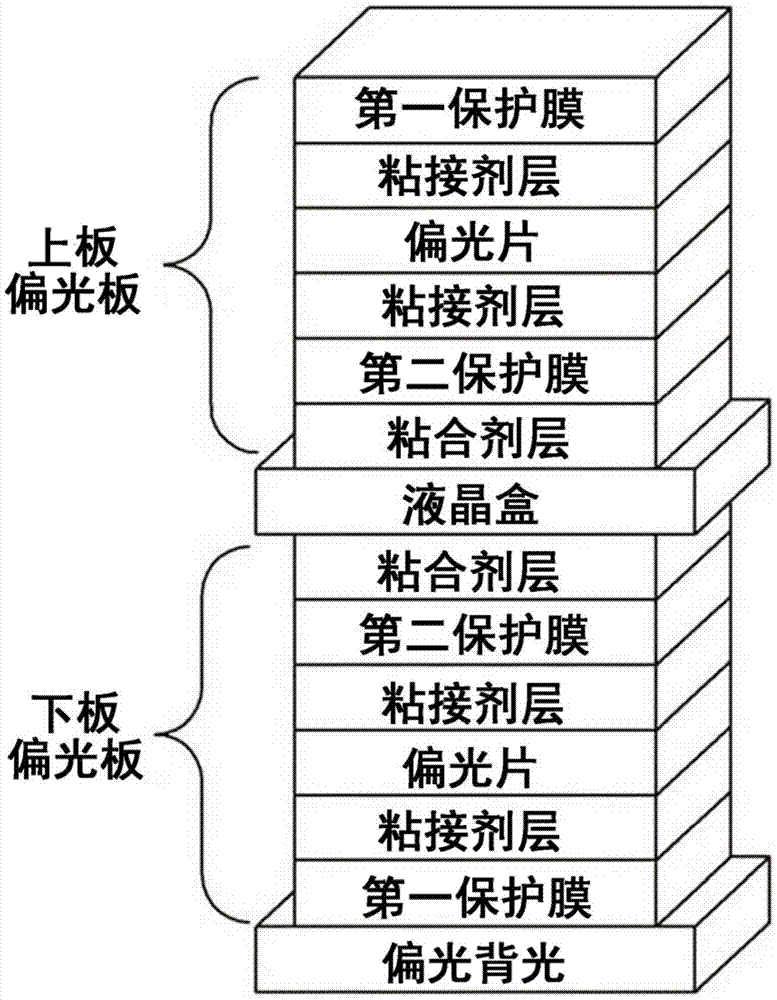

[0108] The actual measurement data of each optical film, liquid crystal cell and backlight of the present invention are as follows: figure 2 The structure shown is laminated on TECHWIZ LCD. On TECH WIZ LCD, the liquid crystal cell of the 55-inch PS-VA mode liquid crystal display device is parameterized and laminated.

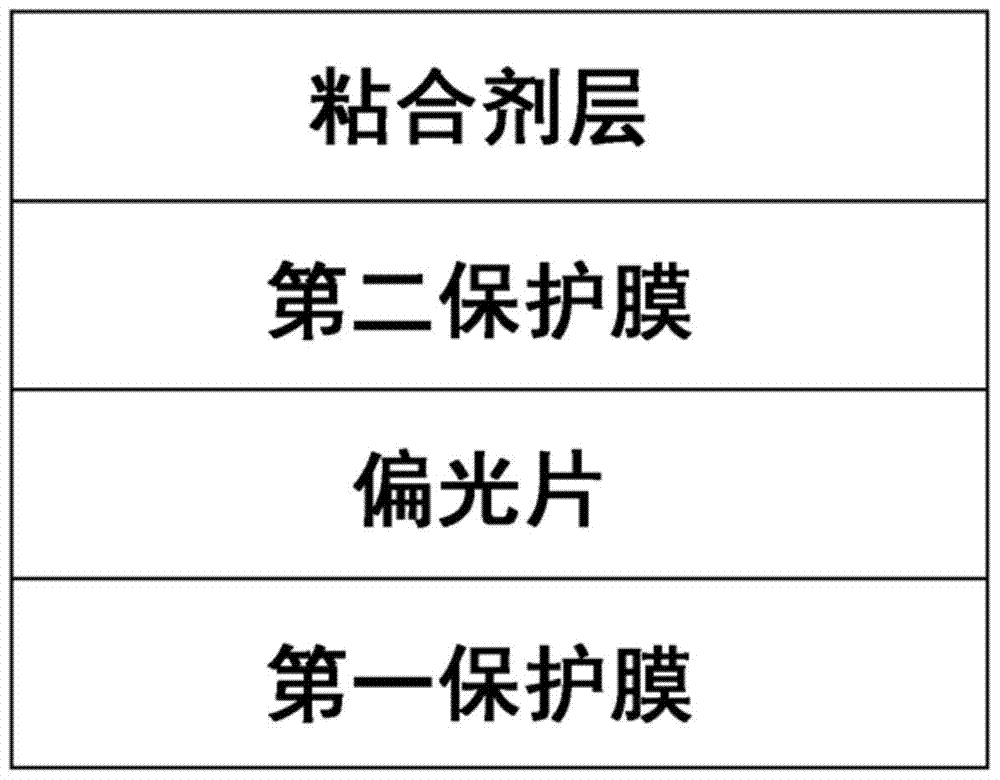

[0109] The liquid crystal display device is composed of a polarized backlight, a PS-VA mode liquid crystal cell of a lower polarizing plate and an upper polarizing plate. The upper polarizing plate and the lower polarizing plate respectively have an adhesive layer, a second protective film, an adhesive layer, a polarizer, an adhesive layer, and a first protective film laminated in order from the liquid crystal cell side.

[0110] The polarizer is added by stretching and dyeing PVA. The absorption axis of the backlight side polarizer is stacked in the vertical direction when viewed from the viewing side, while the absorption axis of the viewing side polarizer i...

Embodiment 2

[0126] Example 2: VA mode

[0127] Although carried out in the same manner as in Example 1, each of the first protective films of the upper plate and the lower plate is uniaxially stretched in the MD direction, and laminated with a front retardation value (RO) of 250 nm under a light source of 589 nm and Modified polystyrene film (PS) with a refractive index ratio (NZ) of 0.

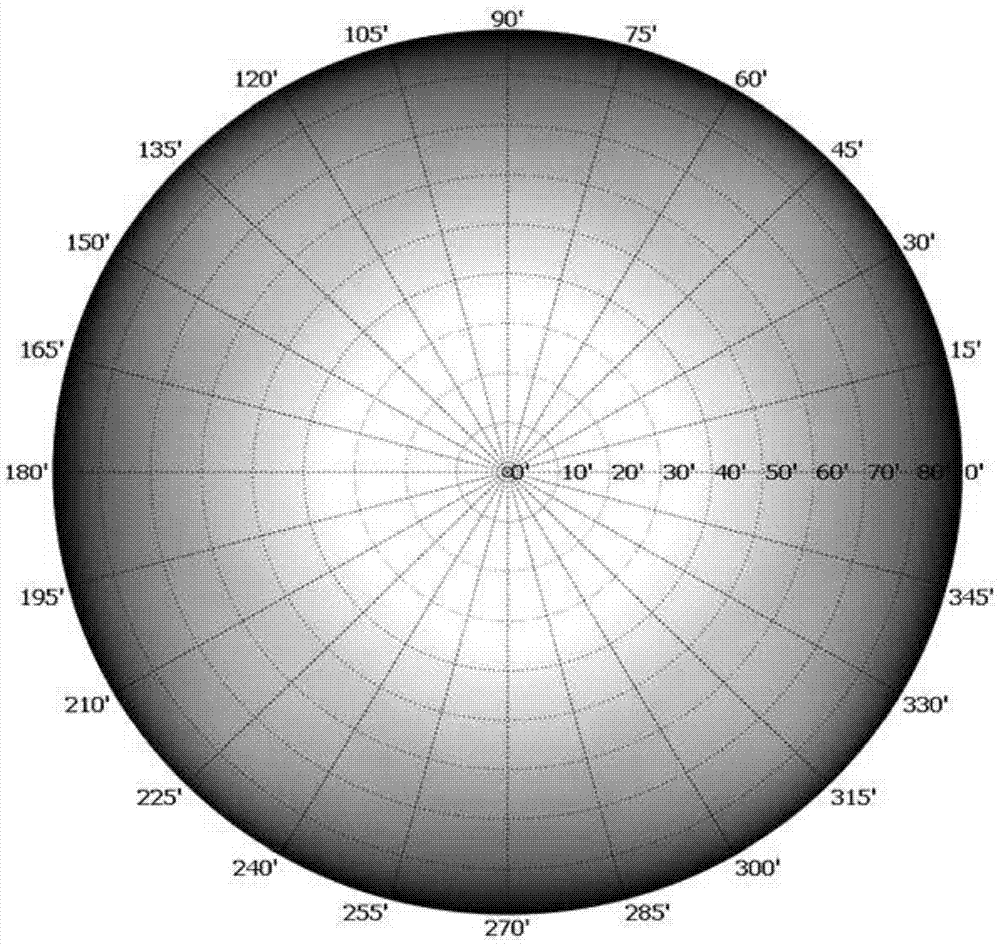

[0128] Figure 4 As a result of applying a voltage to the liquid crystal cell of the liquid crystal display device and counting rainbow spots from various directions, it was confirmed that no rainbow spots occurred at all.

Embodiment 3

[0129] Example 3: VA mode

[0130] Although carried out in the same manner as in Example 1, each first protective film of the upper plate and the lower plate is uniaxially stretched in the MD direction, and laminated with a front retardation value (RO) of 150 nm under a light source of 589 nm and Polyethylene terephthalate film (PET) having a refractive index ratio (NZ) of 1.

[0131] Figure 5 As a result of applying a voltage to the liquid crystal cell of the liquid crystal display device and counting rainbow spots from various directions, it was confirmed that no rainbow spots occurred at all.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com