Separator device for a potato harvester

A separation device and harvester technology, applied in excavation harvesters, harvesters, solid separation and other directions, can solve the problem of not designing a fluid separation device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

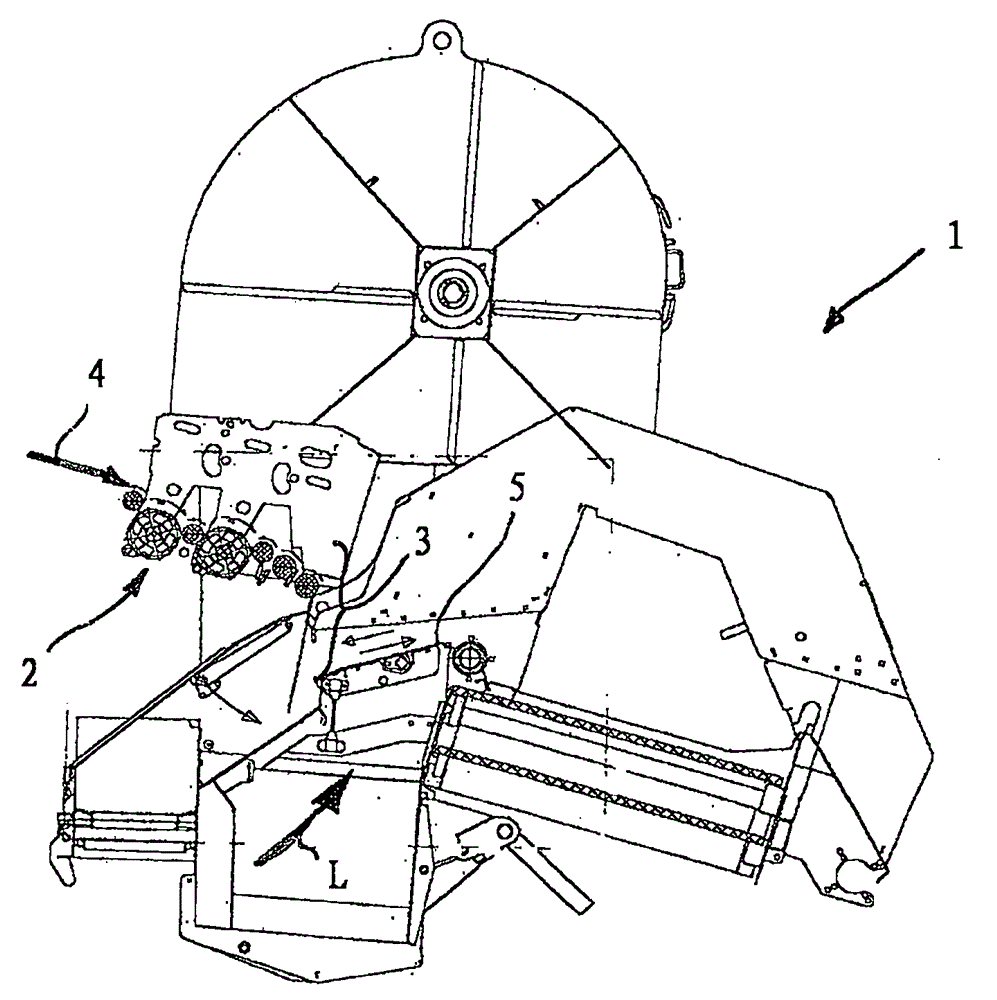

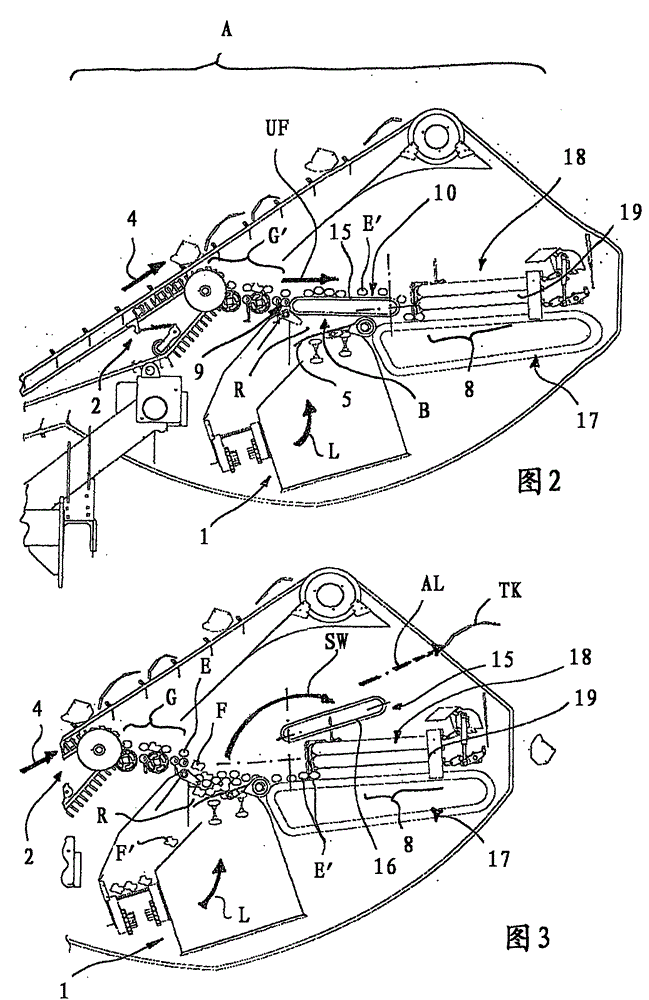

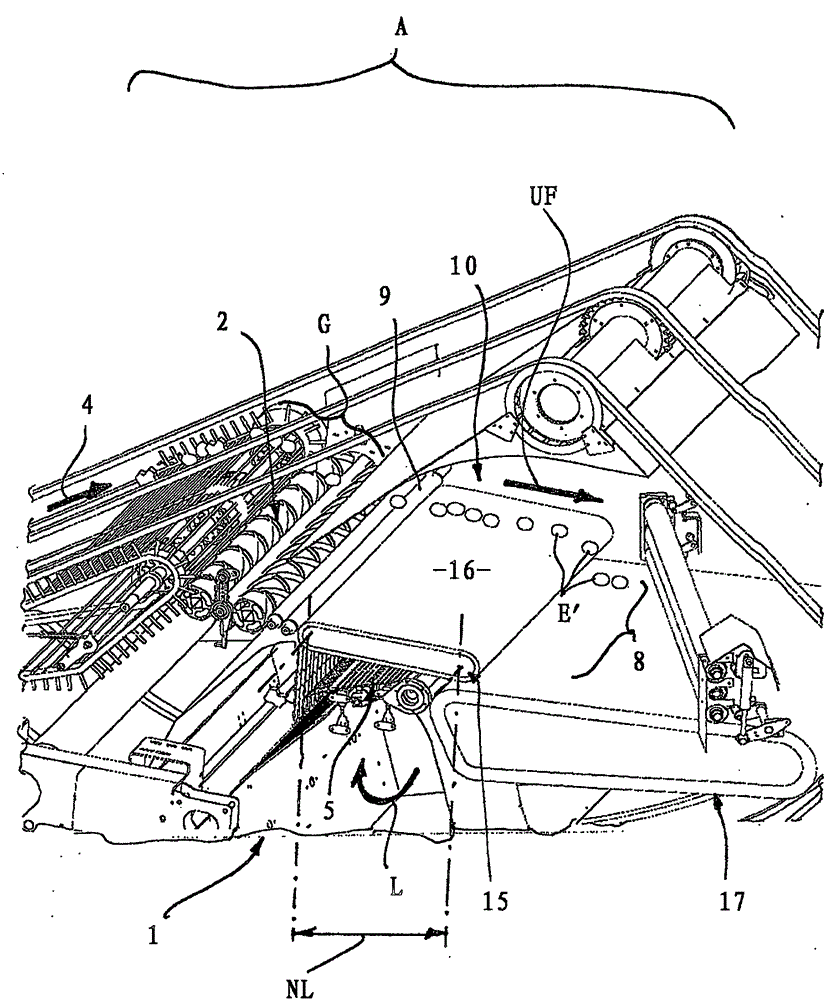

[0033] figure 1 A prior art separation device 1 is shown, according to figure 2 It is shown integrated into a potato harvester A. Such a separating device 1 is used to separate potatoes or similar crops E from a mixture G with clods, mud and other solids F. In this system, the mixture G is supplied as a conveying stream 4 from a receiving area of the machine A (not further shown) by means of a conveying device indicated generally at 2 . After this conveying section, the mixture G reaches the drop 3 ( figure 1 ) area from which the gradually loosened mixture G moves onto the blocking element 5 in the area of the separating device. In this area the basic constituents of the actual "sorting" of the mixture G, where the crop E' and the solids F' are further guided separately in corresponding substantially opposite conveying directions (arrows 6, 7; Figure 5 ). The separation process is supported by an air flow L generated by means of an external blower (not shown), so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com