Tobacco homogenization regulation and control interval division method

A technology of homogenization and division, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of unstable chemical value range, inability to control the mean value of chemical value well, and large chemical value range at both ends, etc., to achieve Save hardware management costs, reduce operation risks, and improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical scheme of the present invention will be further described below in conjunction with specific embodiments:

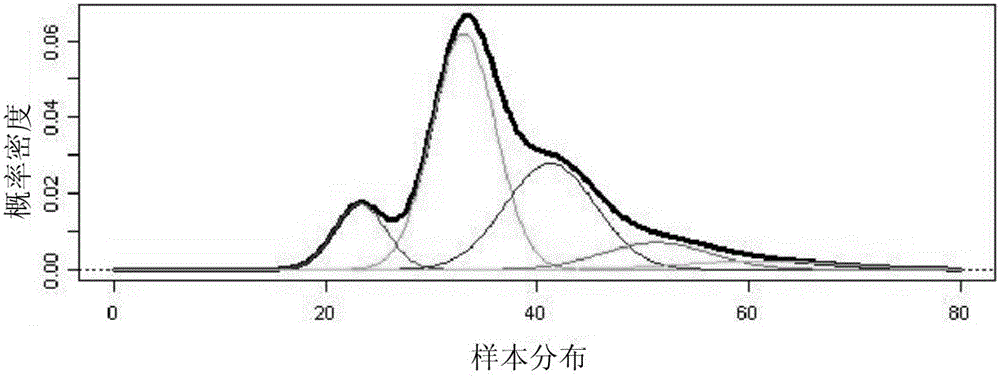

[0039] Step (1) Obtaining the nicotine information (that is, one of the chemical value information) of the tobacco leaves in the cigarette box;

[0040] Step (2) sorting the nicotine information of the tobacco leaves in a positive sequence;

[0041] Step (3) divides the number of chemical value intervals from 2 to k, and k is the number of interval divisions of the largest chemical composition;

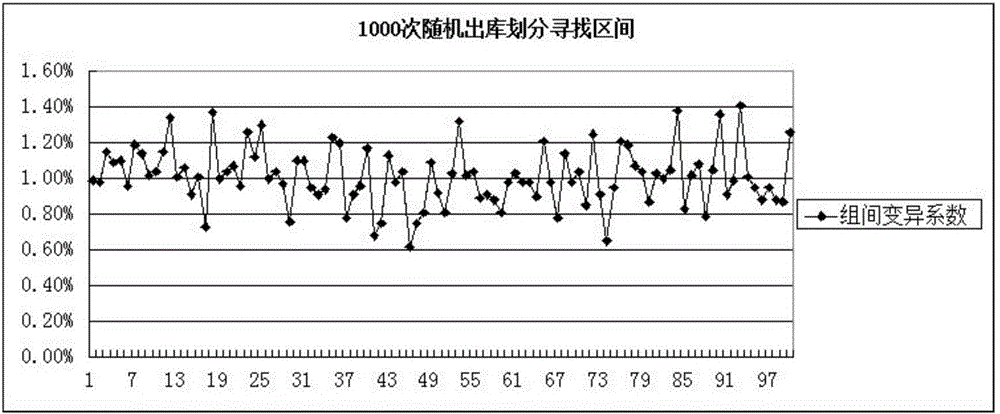

[0042] Step (4) the division method of m intervals is according to m-1 point randomly locates the endpoint of the interval, and locates 1000 times; m intervals refer to any one of the above-mentioned 2~k division numbers;

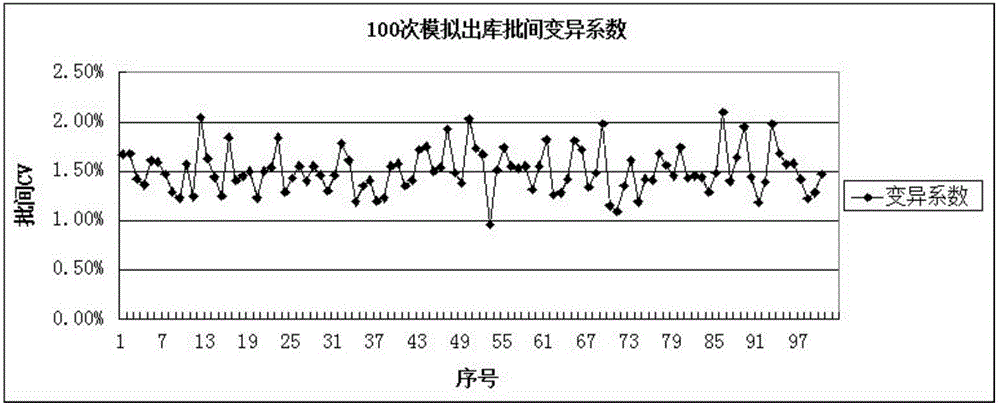

[0043] Step (5) divide the interval (the last elevated warehouse / outbound interval of the flat warehouse), and count the distribution of the chemical value of each interval;

[0044] Step (6) According to the outbound queue table genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com