Blending device and blending method of H2O2

A technology of hydrogen peroxide and water pipes, which is applied in mixing methods, chemical instruments and methods, hydrogen peroxide, etc., and can solve problems such as inaccurate concentration of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

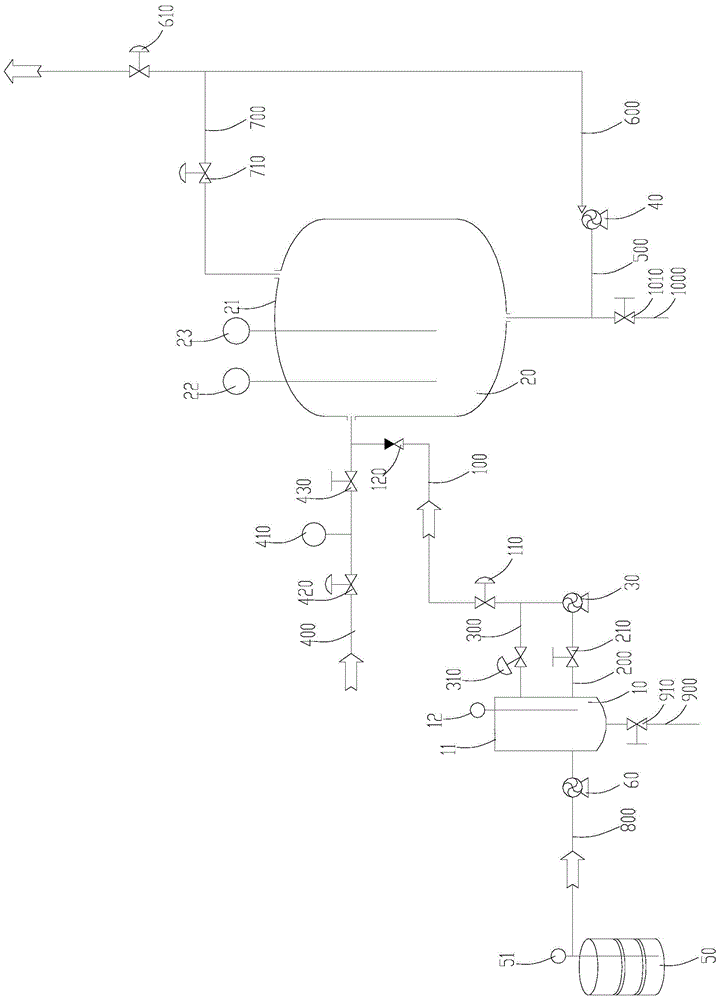

[0028] like figure 1 As shown, a hydrogen peroxide preparation device includes a stock solution pretreatment tank 10, a hydrogen peroxide preparation main tank 20, and a first pump 30 arranged between the stock solution pretreatment tank 10 and the hydrogen peroxide preparation main tank 20. The first pump 30 It communicates with the hydrogen peroxide preparation main tank 20 through the first pipeline 100, and the first on-off valve 110 is provided on the first pipeline 100, and the raw liquid pretreatment tank 10 and the first pump 30 pass through the second The pipeline 200 communicates, and the communication pipeline between the first on-off valve 110 and the first pump 30 is provided with a third pipeline 300 communicated with the raw liquid pretreatment tank 10, and the third pipeline 300 is provided with a second On-off valve 310, the upper end of the raw liquid pretreatment tank 10 is provided with a first vent hole 11.

[0029] Due to the strong oxidation and instabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com