Method for treating dye wastewater by Fe<0>/PDS system

A dye wastewater, treatment method technology, applied in the oxidation water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult treatment, complex components, difficult organic pollutants, etc. Reduce cost, improve degradation rate, improve degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

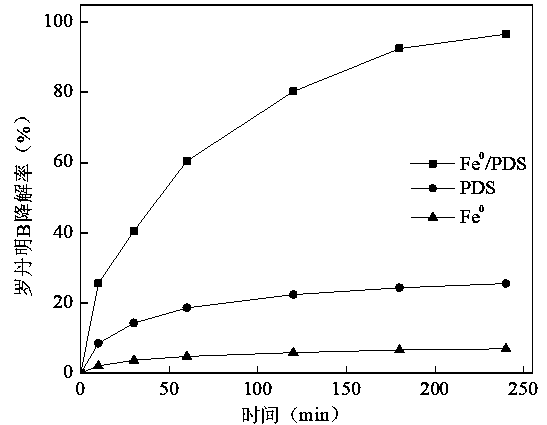

[0015] Experimental conditions: the initial pH is 7, Fe 0 The dosage is 0.5 g / L, the dosage of PDS is 2 g / L, and the reaction temperature is 25°C. Depend on figure 1 It can be seen that when zero-valent iron is added alone, the degradation rate of rhodamine B is only 6.9%, basically no removal, which shows that zero-valent iron has a poor adsorption effect on rhodamine B and cannot effectively degrade rhodamine B.

[0016] When PDS was added alone, the degradation rate of rhodamine B was 25.6%. PDS itself has a certain oxidation ability. When PDS is dissolved in aqueous solution, a hydrolysis reaction will occur to generate persulfate (S 2 o 8 2- ), its oxidation-reduction potential is 2.01 V, which can effectively oxidize some pollutants, but its oxidation ability is relatively weak. Therefore, the degradation rate of rhodamine B in the reaction system is not high.

[0017] Fe 0 The degradation rate of rhodamine B in the / PDS system was 96.2%, compared with that of Fe ...

Embodiment 2

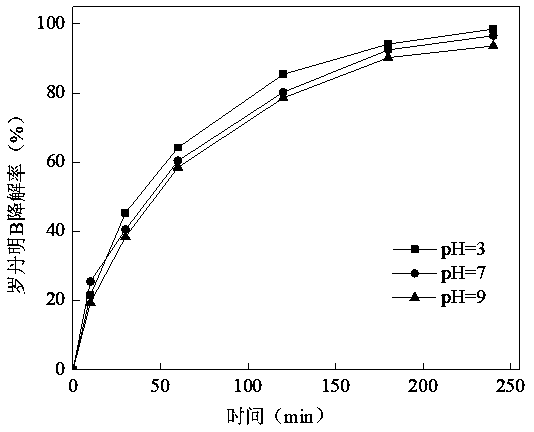

[0019] Experimental conditions: Fe 0 The dosage was 0.5 g / L, the dosage of PDS was 2 g / L, the reaction temperature was 25 ℃, and the initial pH were 3, 7, and 9, respectively.

[0020] Depend on figure 2 It can be seen that under acidic, neutral and alkaline conditions, Fe 0 The / PDS system has a high degradation rate for rhodamine B dye wastewater, but the degradation rate is slightly different. After 30 min of reaction, the degradation rate reached 45.4 % under acidic conditions, 40.5 % under neutral conditions, and 38.4 % under alkaline conditions.

Embodiment 3

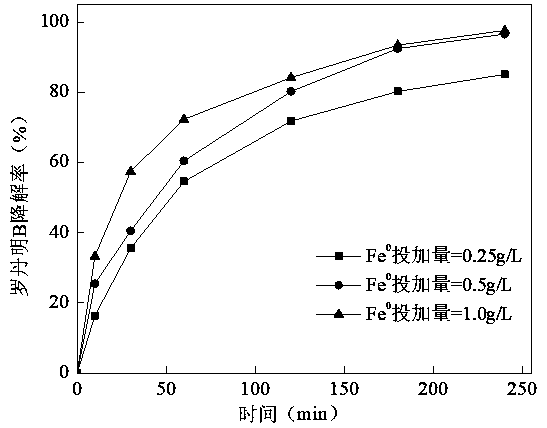

[0022] Experimental conditions: PDS dosage is 2 g / L, initial pH is 7, reaction temperature is 25 °C, Fe 0 The dosage is 0.25, 0.5, 1.0 g / L respectively. Depend on image 3 It can be seen that when Fe 0 When the dosage increased from 0.25 g / L to 0.5 g / L, the degradation rate of Rhodamine B also increased from 85.1 % to 96.6 %, but when Fe 0 When the dosage was increased to 1 g / L, the removal rate did not increase significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com