Vanadium-free SCR denitration catalyst and preparation method thereof

A technology of denitration catalyst and plasticizer, applied in the field of denitration catalyst, can solve the problems of toxic effects on human body and environment, narrow operating temperature window of catalyst, etc., and achieve the effect of being beneficial to dispersion, improving use safety, and increasing surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

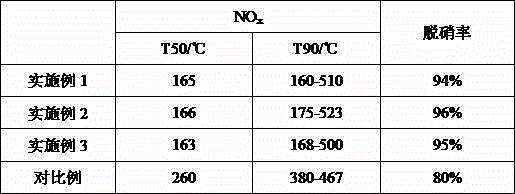

Examples

Embodiment 1

[0056] A vanadium-free SCR denitration catalyst is prepared from the following components in parts by weight:

[0057] 8 parts of diatomaceous earth;

[0058] 13 parts of nano titanium dioxide;

[0059] 6 parts of molecular sieve;

[0060] 9 parts of lanthanum oxide;

[0061] 4 parts of cerium oxide;

[0062] 20 parts of cross-linked chitosan;

[0063] 3 parts talcum powder;

[0064] 6 parts of simethicone;

[0065] 2 parts of phenolic resin;

[0066] 3 parts of dolomite;

[0067] 2 parts of α-cyanoacrylate;

[0068] 4 parts of polytetrafluoroethylene powder;

[0069] 3 parts polyethylene powder;

[0070] 0.2 parts of bis(2-ethylhexyl) phthalate;

[0071] 0.3 parts of dimethyl phthalate;

[0072] Span - 801 copies;

[0073] 2 parts sodium lauryl sulfate;

[0074] 2 parts of polyoxyethylene ether;

[0075] 6 parts of deionized water.

[0076] The preparation technology of a kind of vanadium-free SCR denitration catalyst of the present invention is as follows:

[...

Embodiment 2

[0088] A vanadium-free SCR denitration catalyst is prepared from the following components in parts by weight:

[0089] 12 parts of diatomaceous earth;

[0090] 15 parts of nano-titanium dioxide;

[0091] 8 parts of molecular sieve;

[0092] 10 parts of lanthanum oxide;

[0093] 5 parts of cerium oxide;

[0094] 22 parts of cross-linked chitosan;

[0095] 4 parts of talcum powder;

[0096] 7 parts of simethicone;

[0097] 3 parts of phenolic resin;

[0098] 3 parts of dolomite;

[0099] 4 parts of α-cyanoacrylate;

[0100] 5 parts of polytetrafluoroethylene powder;

[0101] 4 parts of polyethylene powder;

[0102] 0.5 part of bis(2-ethylhexyl) phthalate;

[0103] 0.5 parts of dimethyl phthalate;

[0104] Span - 802 copies;

[0105] 3 parts sodium lauryl sulfate;

[0106] 3 parts of polyoxyethylene ether;

[0107] 8 parts of deionized water.

[0108] The preparation process of the vanadium-free SCR denitration catalyst of the present invention is as follows:

[...

Embodiment 3

[0120] A vanadium-free SCR denitration catalyst is prepared from the following components in parts by weight:

[0121] 15 parts of diatomaceous earth;

[0122] 18 parts of nano-titanium dioxide;

[0123] 12 parts of molecular sieves;

[0124] 12 parts of lanthanum oxide;

[0125] 8 parts of cerium oxide;

[0126] 25 parts of cross-linked chitosan;

[0127] 6 parts of talcum powder;

[0128] 11 parts of simethicone;

[0129] 3 parts of phenolic resin;

[0130] 4 parts of dolomite;

[0131] 5 parts of α-cyanoacrylate;

[0132] 7 parts of polytetrafluoroethylene powder;

[0133] 5 parts of polyethylene powder;

[0134] 1 part of bis(2-ethylhexyl) phthalate;

[0135] 1 part of dimethyl phthalate;

[0136] Span - 805 copies;

[0137] 4 parts sodium lauryl sulfate;

[0138] 6 parts of polyoxyethylene ether;

[0139] 14 parts of deionized water.

[0140] The preparation process of the vanadium-free SCR denitration catalyst of the present invention is as follows:

[0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap