Washing equipment for high-ash, high-mud and high-gangue coal

A kind of equipment and high-sludge technology, applied in the field of coal slime separation process, can solve the problems of low product recovery rate and production efficiency, difficult to solve the problem of high-ash fine mud entrainment and the influence of the flotation process of continuous minerals, and achieve The effects of high flotation efficiency, reduced separation pressure, and reduced coal flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

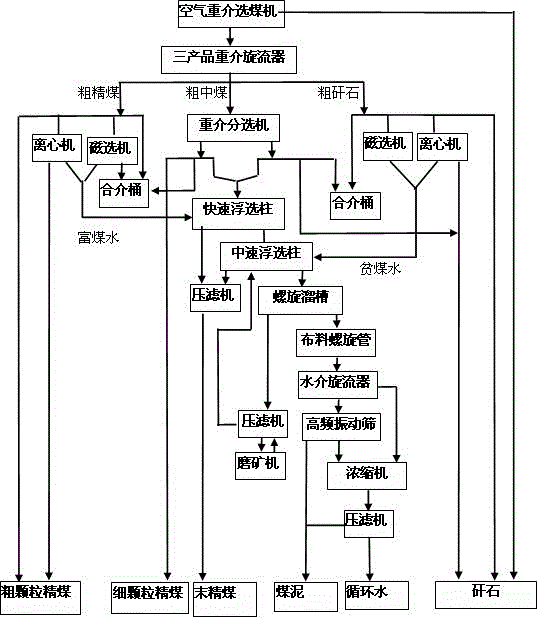

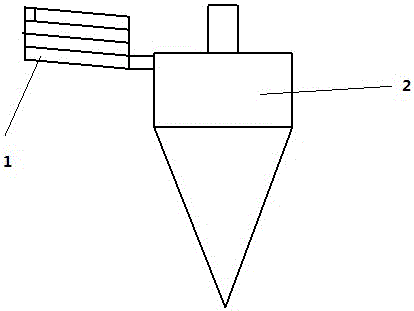

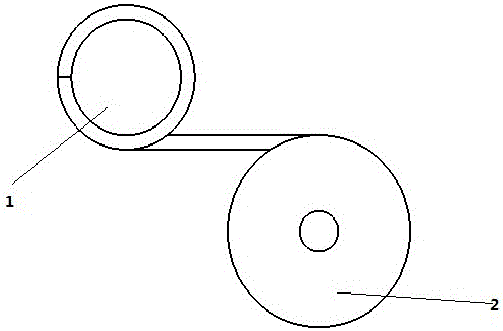

[0018] like figure 1 As shown, the raw coal is selected into the air-dense medium coal separator. The air-dense medium coal separator is a dry-type coal separator, which adopts air-dense medium fluidized bed dry separation. The coal separator is mainly composed of an air chamber and an air distribution plate. , Scraper conveying device and other components. The sorting process of the material (raw coal) in the sorter is: the 100-13mm particle size raw coal after screening and the dense medium are added to the sorter at the same time. The pressurized gas with a certain speed is input into the bottom air chamber, and evenly acts on the heavy medium after passing through the air distribution plate to form a uniform and stable gas-solid fluidized suspension with a certain density. According to Archimedes' law, light and heavy materials are layered according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com