Washing equipment for coal with much ash, mud and gangue

A high-slime and gangue technology is applied in the field of sorting equipment for difficult-to-separate coal slime, and can solve problems such as the entrainment of high-ash fine mud and the influence of the flotation process of conjoined minerals, low product recovery rate and production efficiency, etc. , to achieve high flotation efficiency, reduce separation pressure, and reduce coal flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be further described below in conjunction with the accompanying drawings:

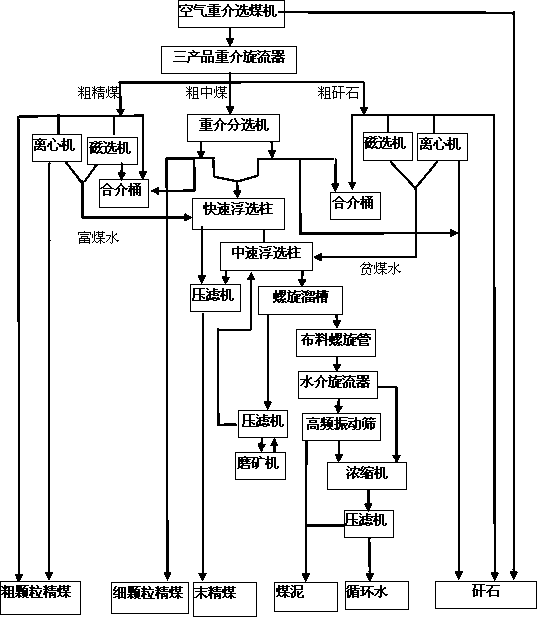

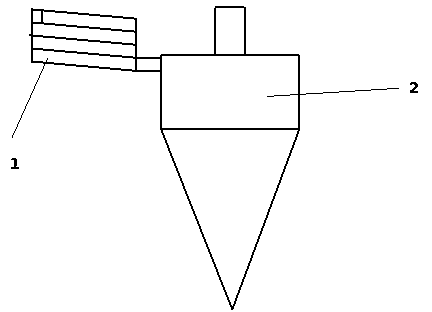

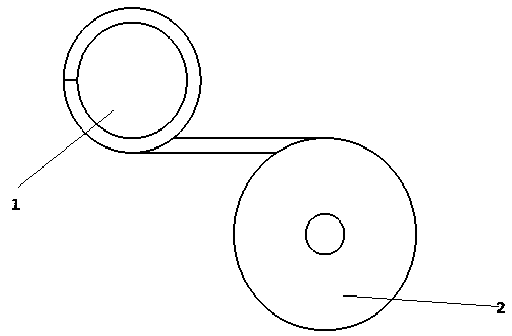

[0018] like figure 1 As shown in the figure, the raw coal is selected into the air dense medium coal preparation machine. The air dense medium coal preparation machine is a dry type coal preparation machine, which adopts the air dense medium fluidized bed dry separation. The coal preparation machine is mainly composed of an air chamber, an air distribution plate , scraper conveyor and other parts. The separation process of the material (raw coal) in the separator is as follows: the 100-13mm particle size raw coal and the heavy medium after screening are simultaneously added to the separator. The pressurized gas with a certain speed is input into the bottom air chamber, and after passing through the air distribution plate, it evenly acts on the heavy medium to form a uniform and stable gas-solid fluidized suspension with a certain density. Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com