Automatic rotary cutting device for thin-wall pipe fittings and rotary cutting method with automatic rotary cutting device

A technology of rotary cutting device and pipe fittings, which is applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problems of unsuitable fixture structure and tool shape, labor-intensive, low degree of automation, etc., and achieves the structure and control method. The effect of optimizing, avoiding environmental pollution, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

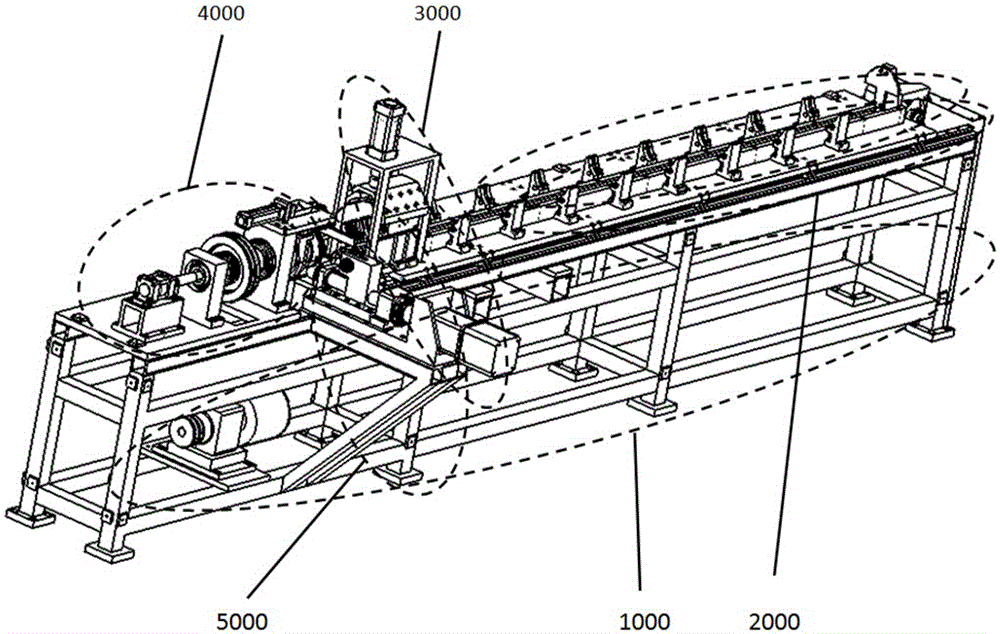

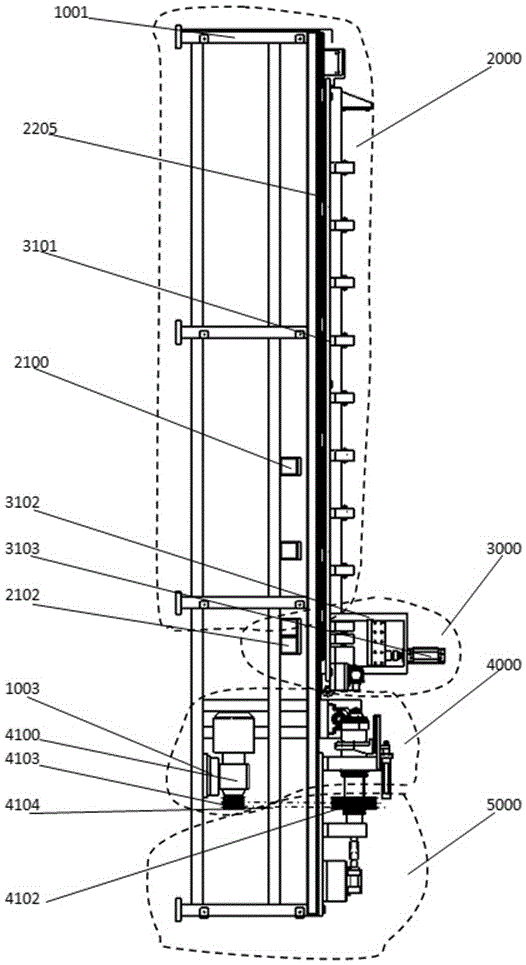

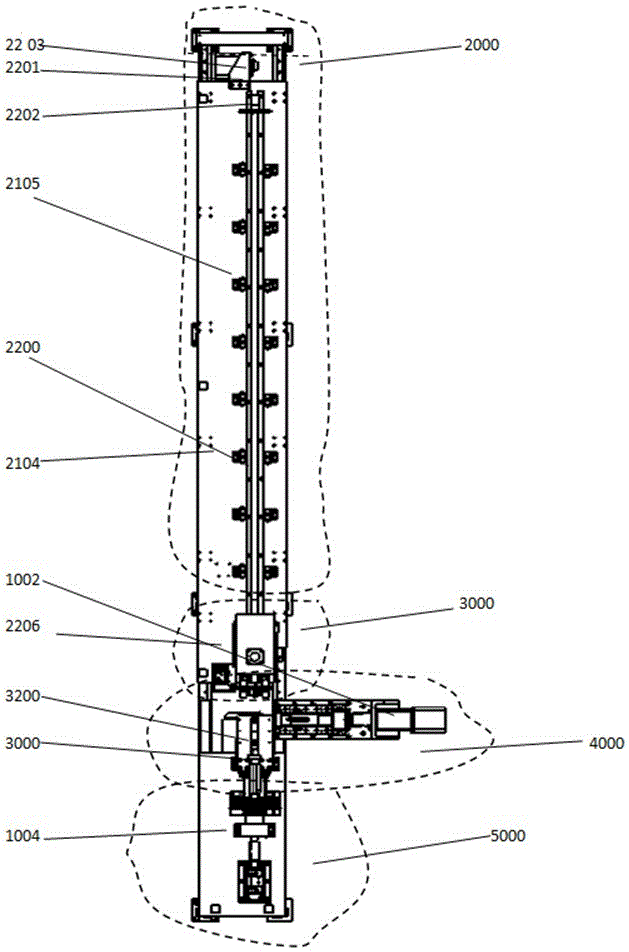

[0035] see figure 1 , an automatic rotary cutting device for thin-walled pipes, including a bracket platform assembly 1000 , a feeding assembly 2000 , a clamping assembly 3000 , a rotary cutting assembly 4000 and a feeding assembly 5000 .

[0036] The support platform assembly 1000 is a rectangular block and is fixedly installed on the foundation.

[0037] A feeding assembly 2000 is provided on one end of the support platform assembly 1000 . Note that the end of the loading assembly 2000 is the tail of the support platform assembly 1000 .

[0038] At the other end of the support platform assembly 1000, that is, at the head of the support platform assembly 1000, a clamping assembly 3000 and a blanking assembly 5000 are respectively provided.

[0039] A rotary cutting assembly 4000 is installed on the support platform assembly 1000 between the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com