Dedicated wrench for fork truck

A wrench and forklift technology, applied in the field of wrenches, can solve the problems of large pollution in the production process, poor quality of wrenches, short service life, etc., and achieve the effects of good use feeling, increased service life and solving pollution problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

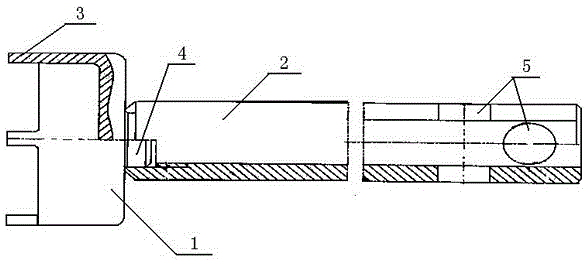

[0011] Such as figure 1 A forklift special wrench is shown, including a socket head 1 and a sleeve rod 2 connecting the socket head; the socket head 1 is a cylindrical hollow stamping part, and four teeth are evenly distributed at the open end of the socket head at the center of the circle. Claw 3, tooth claw 3 quenching.

[0012] The sleeve head is directly stamped from manganese steel plate, and then the four claws at the opening end are processed.

[0013] A connection inserting rod 4 is welded at the connecting end of the sleeve head 1 and the sleeve rod 2 . Connecting the plunger 4 can quickly realize that the socket head is connected with the sleeve rod, and then welded, so that the structure is firmer.

[0014] The sleeve rod 2 is a hollow cylindrical metal rod, and two pairs of mutually perpendicular through holes 5 are arranged on the metal rod far away from the sleeve head, so as to facilitate insertion of the force arm. In order to facilitate the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com