Disassembly tool for oil drain plug of engine oil bottom shell

A technology for engine oil and dismantling tools, which is applied in the manufacture of tools and hand-held tools, can solve problems such as low work efficiency, long waiting time, and long disassembly time, and achieve the effects of improving work efficiency, strong practicability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

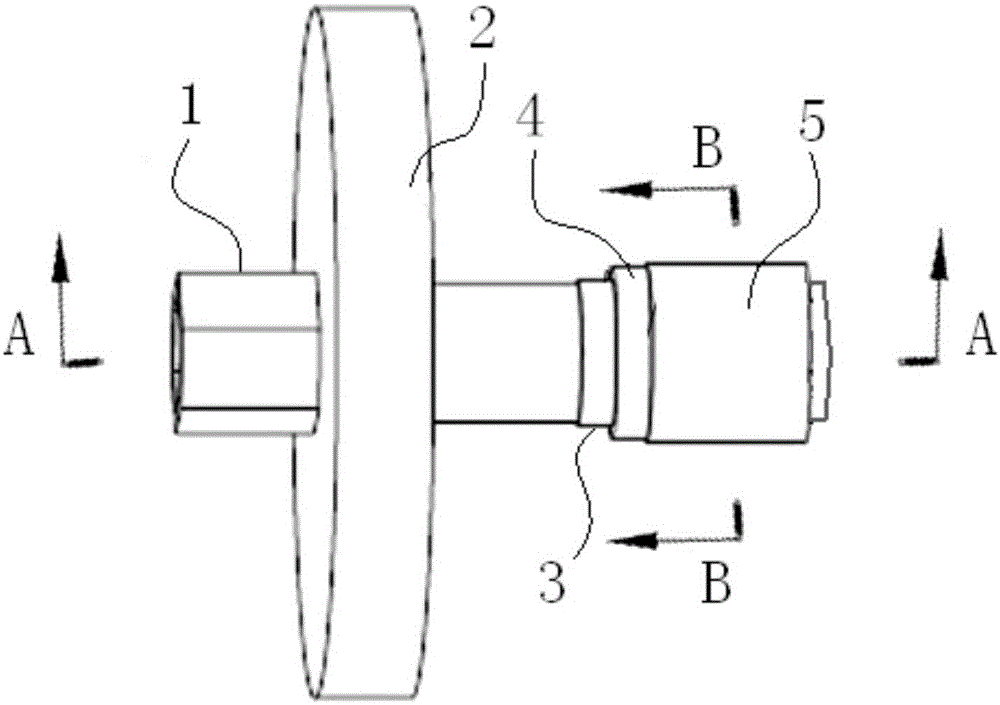

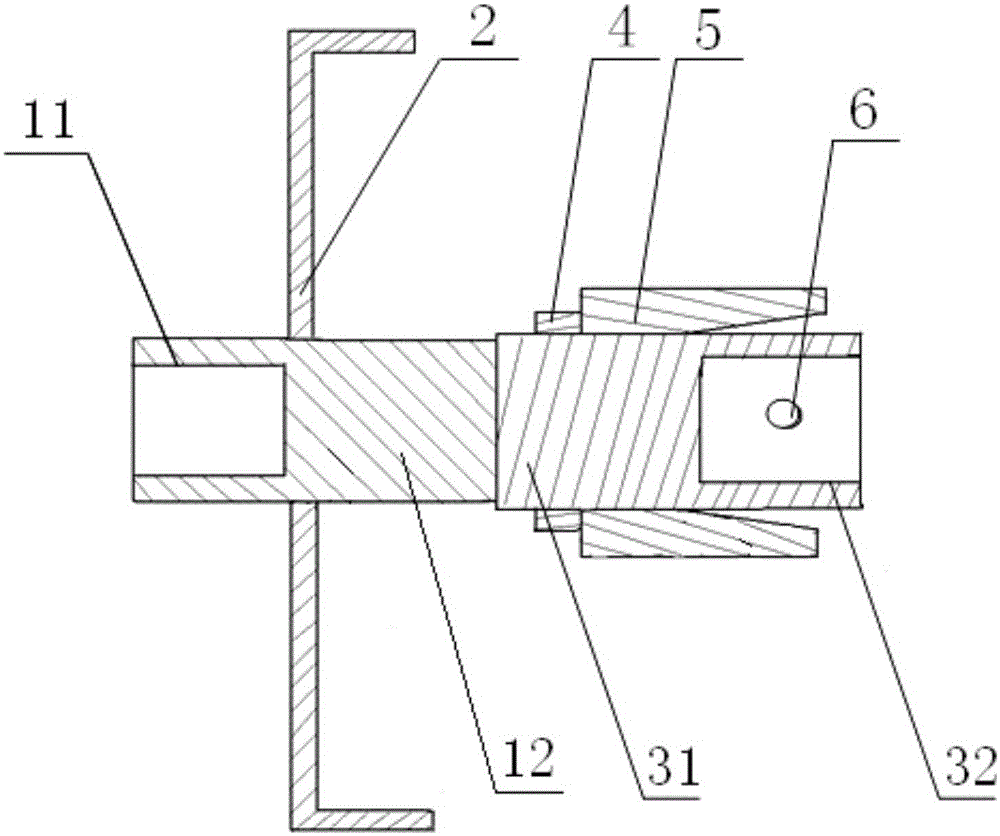

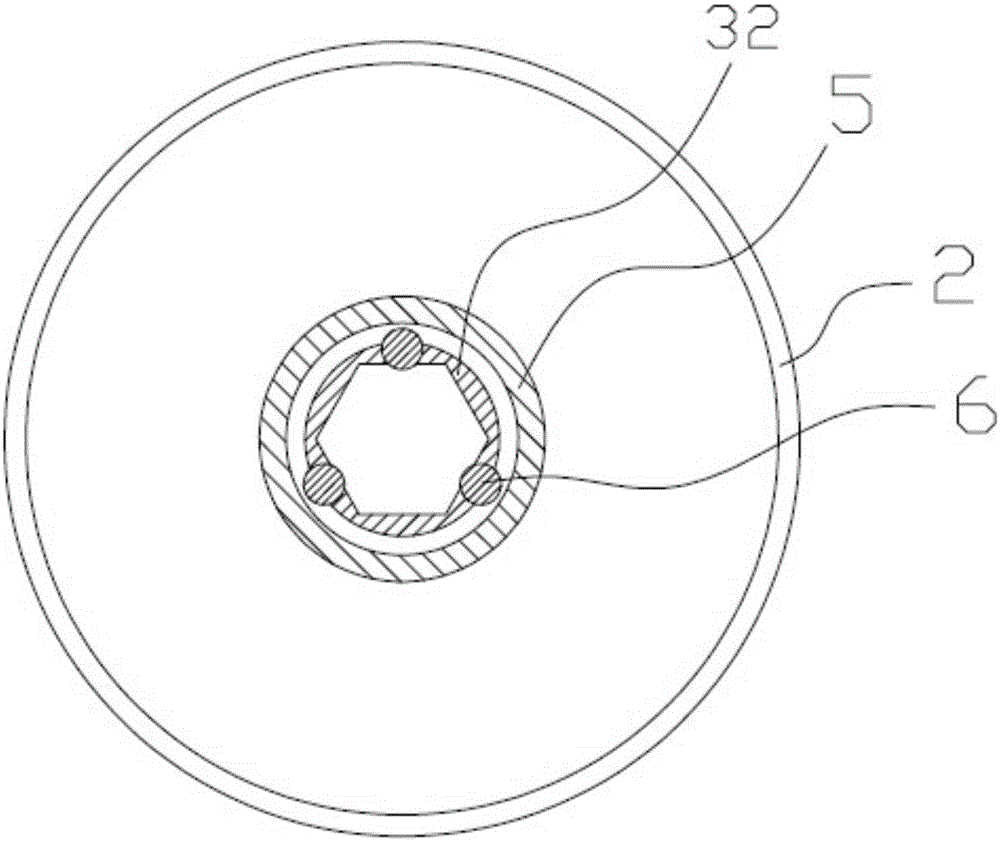

[0020] Example 1: Such as Figure 1 to Figure 3 The removal tool for the oil drain plug of the engine oil pan shown includes a handle 1, an oil deflector 2, a plug sleeve 3, a limit retaining ring 4 and a locking ring 5; the oil deflector 2 has a bent edge The handle 1 passes through the center of the oil deflector 2 and is welded to the oil deflector 2. The part of the handle 1 on the left side of the oil deflector 2 is a hex nut 11, and the part of the handle 1 on the right side of the oil deflector 2 is Connecting cylinder 12; the left part of screw plug sleeve 3 is stud 31, the right part of screw plug sleeve 3 is hexagonal sleeve 32, the left end of stud 31 is welded with the right end of connecting cylinder 12, and the interval between hexagonal sleeve 32 There is a round hole on each of the three inner walls (a total of three round holes, and the angle between two adjacent round holes is 120°), and a steel ball 6 is embedded in each round hole (a total of three steel ...

Embodiment 2

[0027] Example 2: see Figure 5 , the structure of the dismantling tool of the oil drain plug of the engine oil pan is mostly the same as that of Embodiment 1, the difference is that: each of the six inner walls of the hexagonal sleeve 32 is provided with a round hole (a total of six round holes , the angle between two adjacent circular holes is 60°), and a steel ball 6 (a total of six steel balls) is embedded in each circular hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com