Mold for improving forming effect

A mold and inner mold technology, applied in the field of plastic sleeve color forming molds, can solve the problems of difficult mold separation, excess material generation, easy assembly errors, etc., to improve the molding effect, reduce manufacturing costs, and prevent secondary processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment

[0022] The present invention is described further:

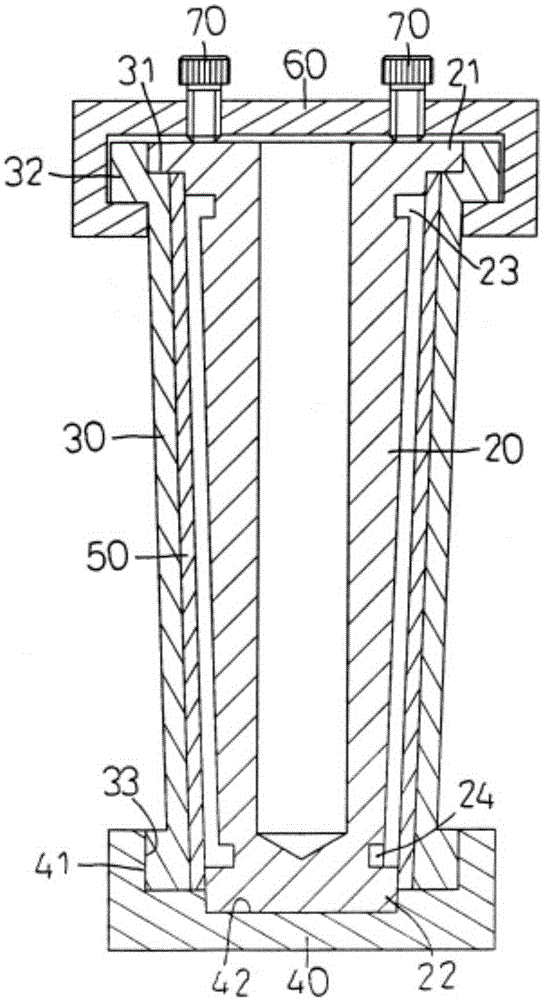

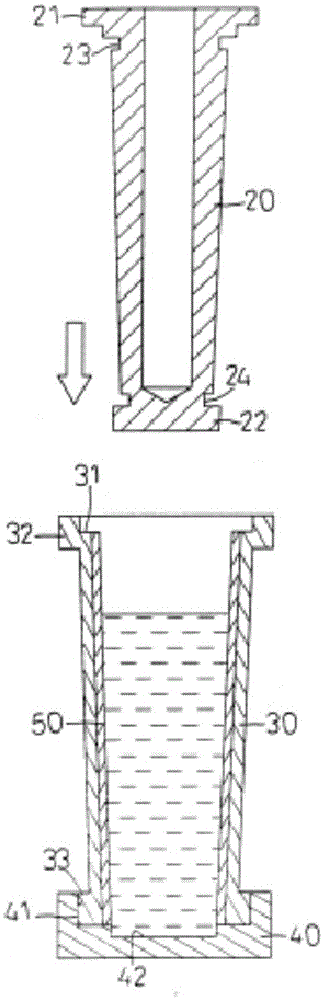

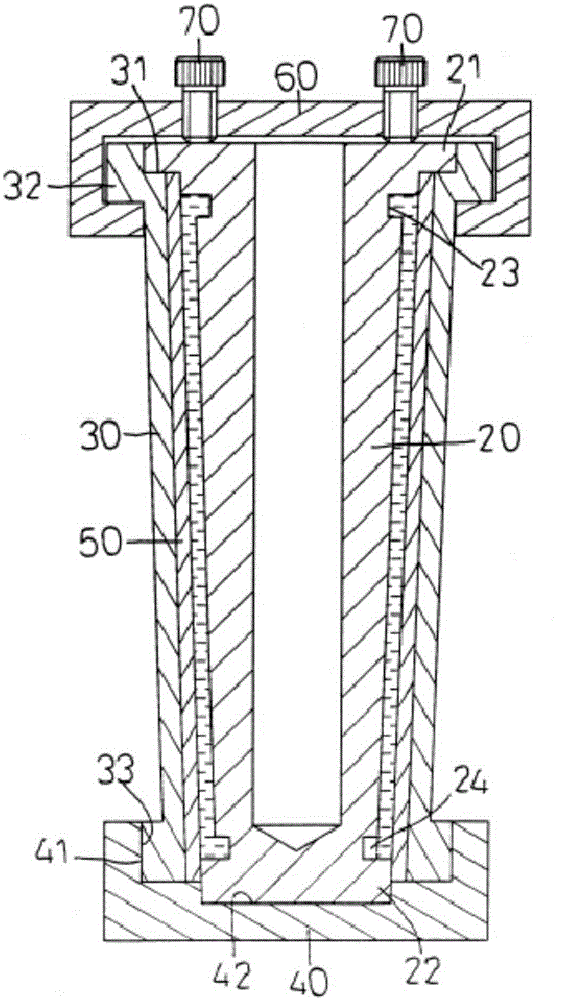

[0023] Such as Figure 1-Figure 3 As shown, a mold with improved molding includes an inner mold 20, an outer mold 30, a bottom mold 40, a silicone mold 50 and a clamp 60;

[0024] The top of the inner mold 20 is provided with a first step edge 21, the bottom of the inner mold 20 is provided with a second step edge 22, and the inner mold 20 is provided with a first groove 23 and a second groove 24, the first groove 23 and the second groove 24 are arranged between the first step edge 21 and the second step edge 22;

[0025] The silicone mold 50 is arranged between the inner mold 20 and the outer mold 30;

[0026] The top of the outer mold 30 is provided with a concave third step edge 31, through the cooperation between the third step edge 31 and the first step edge 21 on the inner mold 20, the effective reliability between the mold 30 and the inner mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com