Spiral elevator with metering function

A screw elevator, functional technology, applied in the direction of conveyor objects, conveyor control devices, transportation and packaging, etc., can solve the problems of not being able to meet the user's metering needs, without metering functions, etc., to achieve convenient metering and reasonable structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings.

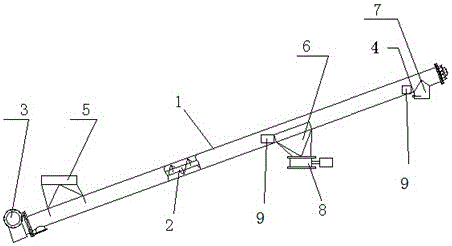

[0008] Such as figure 1 As shown, the screw hoist with metering function of the present embodiment includes a conveying cylinder 1 arranged obliquely upward, a screw shaft 2 installed in the conveying cylinder 1 and a drive motor 3 for driving the screw shaft 2 to rotate; the conveying cylinder The inclination angle of 1 is 20°-40°, the lower end of the conveying cylinder 1 is provided with a feed port 5, and its upper end is provided with a first discharge port 6 and a second discharge port 7, the first discharge port 6 and the second discharge port The discharge port 7 has a certain distance difference and a height difference, and is respectively located at the middle and the top of the conveying cylinder 1. The first discharge port 6 and the second discharge port 7 are respectively equipped with metering sensors 9 for metering. A controllable valve 8 is installed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com