Chain type sediment scraper

A slag scraper and chain-type technology, applied in the direction of grease/oily substance/floating matter removal device, liquid separation, separation method, etc., can solve the problems of easy deformation and aging, scraper deformation and falling off, affecting the working performance of the slag scraper, etc. , to achieve good support, improve performance and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

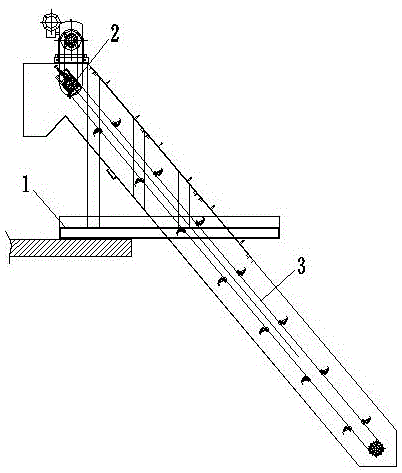

[0018] The present invention comprises a frame 1 and a driving chain 2 arranged on the frame 1, the driving chain 2 is connected with a scraper 3 moving with the driving chain 2;

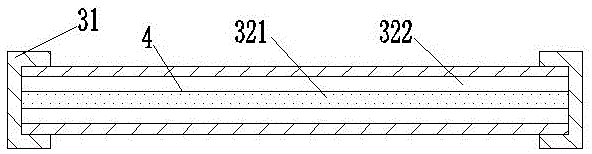

[0019] The scraper 3 includes a metal plate 31 fixed on the drive chain and a corrosion-resistant rubber plate 32 connected to the metal plate 31 to scrape slag.

[0020] The inside of the corrosion-resistant rubber sheet 32 is hollow, and the formed cavity passes through high-pressure gas.

[0021] The cavity is longitudinally divided into an independent inner cavity 321 and an outer cavity 322 , the inner cavity 321 is passed through high-pressure water, and the outer cavity 322 is passed through high-pressure gas.

[0022] The inner cavity 321 and the outer cavity 322 are isolated by the elastic plate 4 .

[0023] The working process of the present invention is as follows: when in use, the driving chain 2 drives the scraper to operate for slag removal. Before use, first pass high-pressure gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com