A kind of preparation method of polyurethane hot melt adhesive capable of realizing rapid positioning

A polyurethane hot melt adhesive, fast technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of poor thermal shock resistance, inability to quickly locate, and poor salt spray resistance. , to achieve good drop resistance, improve initial bonding strength, and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

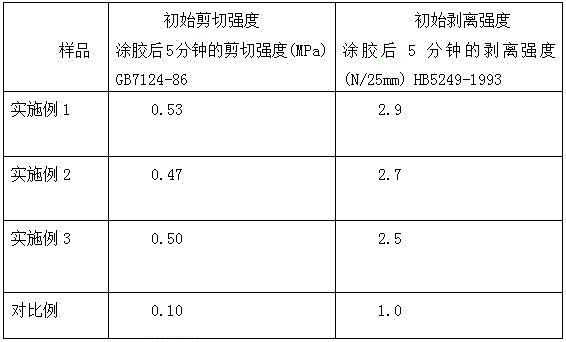

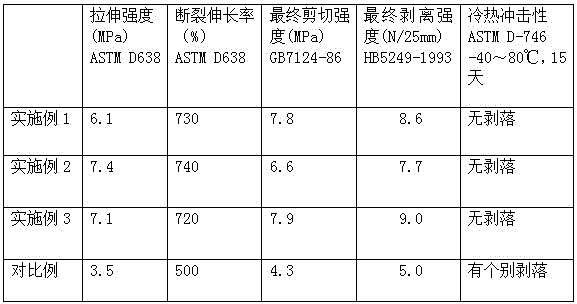

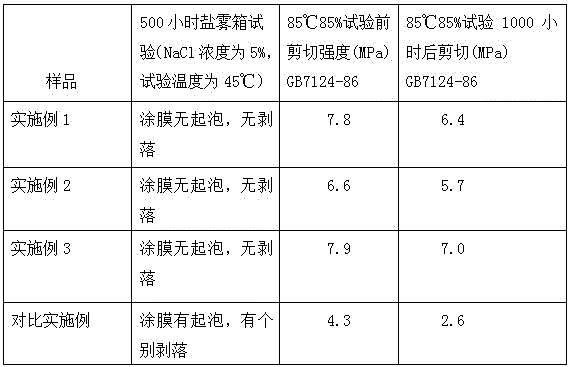

Examples

Embodiment 1

[0030] Example 1: 1) Add 5 parts of reactive plasticizer "Nikanol" resin and 8 parts of hydrogenated bisphenol A into the reactor, dehydrate at 110°C and -0.095MPa for 2h, cool down to 70°C, and add dilauric acid 0.01 part of dibutyltin, 10 parts of German Bayer Desmodur N3300, stirred at 400 rpm, reacted at 70°C for 3 hours. Then add 20 parts of silane modifier Y9669 and react at 70° C. for 5 hours to obtain a silane-terminated modified prepolymer.

[0031] 2) Dehydrate 65 parts of polyester polyol XCP-3000H, 15 parts of polyether polyol PPG220, and 30 parts of acrylic resin DB256 at 120°C and -0.095MPa for 2 hours. After dehydration, add 4,4' di 35 parts of phenylmethane diisocyanate MDI-100, stirred at 700 rpm, reacted at 120°C for 1 hour, then added 5 parts of silane-terminated modified prepolymer prepared in step a, antioxidant 1.0 parts of 264 doses, 0.1 parts of dimorpholino diethyl ether (DMDEE), heated up to 110 ° C, vacuumed to below -0.095 MPa, removed air bubbles ...

Embodiment 2

[0032] Example 2: 1) Add 20 parts of reactive plasticizer "Nikanol" resin and 1 part of hydrogenated bisphenol A into the reaction kettle, dehydrate at 110°C and -0.095MPa for 2h, cool down to 70°C, add stannous octoate 0.05 parts, 45 parts of 2,4-toluene diisocyanate trimer, stirred at 700 rpm, and reacted at 80°C for 1 hour. Then add 30 parts of silane modifier A189 and react at 80° C. for 2 hours to obtain a silane-terminated modified prepolymer.

[0033] 2) Dehydrate 40 parts of polyester polyol POL-356T, 35 parts of polyether polyol PPG204, and 10 parts of acrylic resin DB66 at 120°C and -0.095MPa for 2 hours. After dehydration, add 4,4' di 9 parts of phenylmethane diisocyanate MDI-100, 3 parts of toluene diisocyanate TDI-100, stirred at 400 rpm, reacted at 100°C for 3 hours, and then added the silane-capped modification prepared in step a. 25 parts of permanent prepolymer, 0.02 part of antioxidant 1010, 0.001 part of triethylenediamine, heat up to 110°C, evacuate to bel...

Embodiment 3

[0034] Example 3: 1) Add 13 parts of reactive plasticizer "Nikanol" resin and 4 parts of hydrogenated bisphenol A into the reactor, dehydrate at 110°C and -0.095MPa for 2h, cool down to 70°C, and add dilauric acid 0.04 parts of dibutyltin, 30 parts of triphenylmethane triisocyanate (TTI), stirred at 550 rpm, and reacted at 75°C for 2 hours. Then add 26 parts of silane modifier KH-550 and react at 75° C. for 3.5 hours to obtain a silane-terminated modified prepolymer.

[0035] 2) Dehydrate 33 parts of polyester polyol XCP-3000H, 20 parts of polyester polyol POL-356T, 25 parts of polyether polyol PPG210, and 20 parts of acrylic resin DB68 at 120°C and -0.095MPa for 2 hours After the dehydration is completed, add 14 parts of 4,4' diphenylmethane diisocyanate MDI and 5 parts of toluene diisocyanate TDI 100, stir at 550 rpm, react at 110 ° C for 2 hours, and then add this 15 parts of silane-terminated modified prepolymer prepared in step a, 0.05 part of antioxidant 1076, 0.04 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com