Novel door leaf of fire-proof door

A fire door and door leaf technology, applied in the direction of fire doors, etc., can solve the problems that affect the economic interests of manufacturing enterprises, unfavorable production line flow operation, complex production process, etc., achieve the effect of reducing capital occupation rate, reducing manufacturing process, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

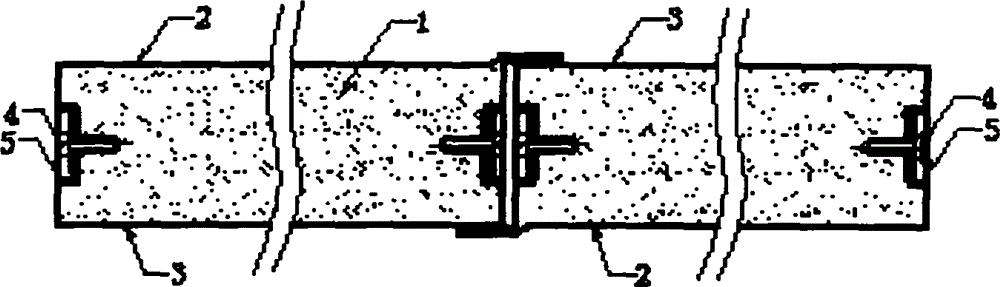

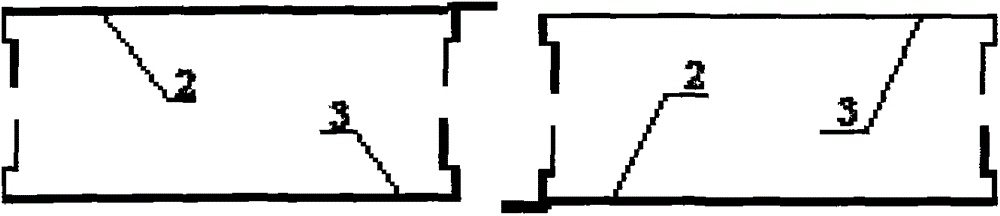

[0014] see figure 1 , figure 2 As shown, through the description of the embodiments, the specific implementation of the present invention, such as the relationship between the various parts involved, the role and working principle of each part, is further explained in detail, to help engineers and technicians in the field understand the present invention. The idea of the invention, a more complete, accurate and in-depth understanding of the technical solution.

[0015] The novel door leaf of the fireproof door of the present invention comprises a core board 1 , a door leaf panel A2 , a door leaf panel B3 , rivets 4 , and threading strips 5 .

[0016] The door panel A2 and the door panel B3 are two paint-free steel plates of different sizes. The door panel A2 and the door panel B3 are butted up and down to form a closed-loop structure to surround the door core panel 1 . The butt joints of the door panel A2 and the door panel B3 are fixed with rivets 4 . It is located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com