High-efficient low-order mode transverse flow CO2 laser

A laser and low-order mode technology, which is applied in lasers, laser components, phonon exciters, etc., can solve the problems of reduced laser output power and photoelectric conversion efficiency, heating of components such as transformer inductance, and low utilization of active regions. Achieve high photoelectric conversion efficiency, increase output power, and expand the effective gain area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited by this.

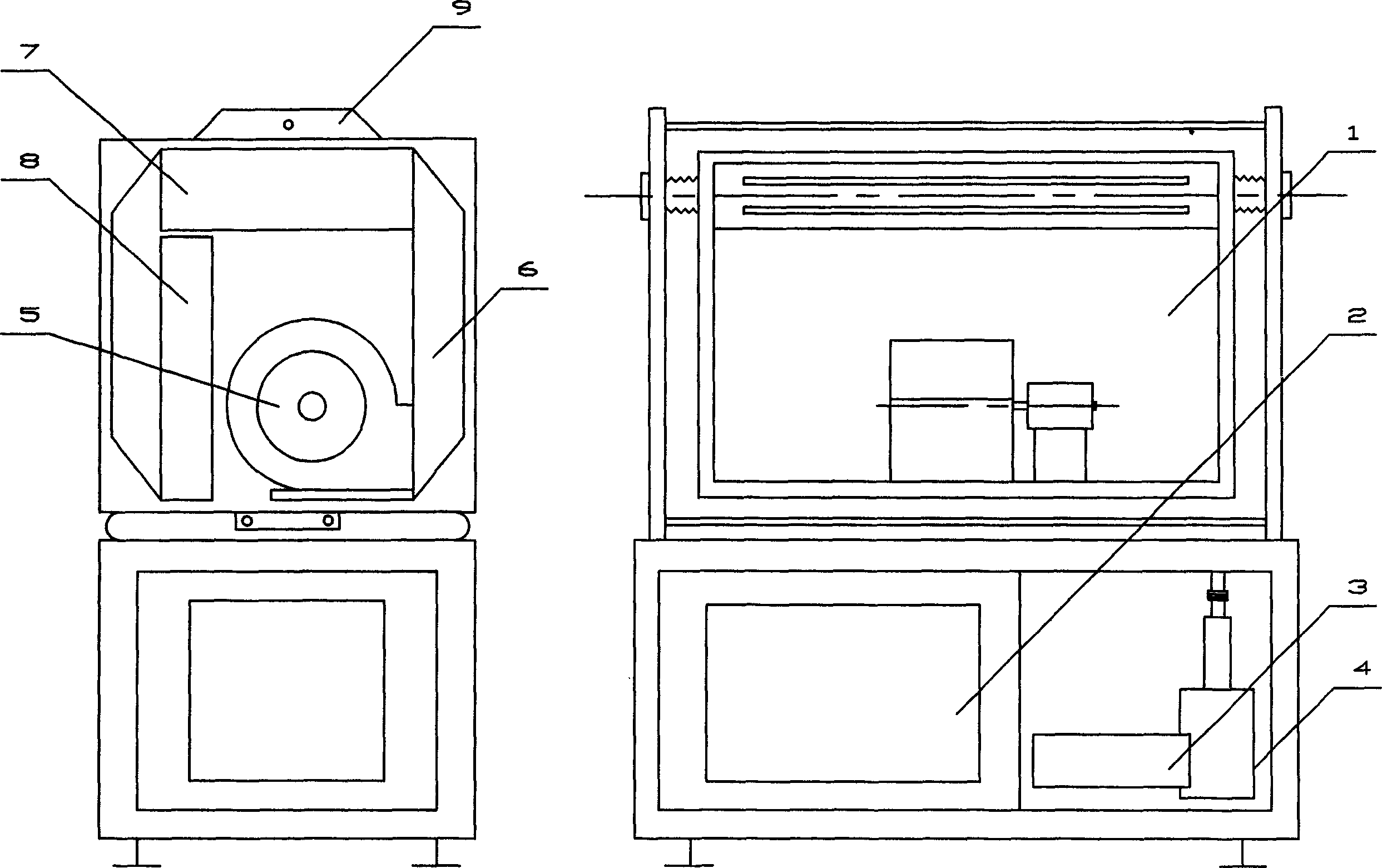

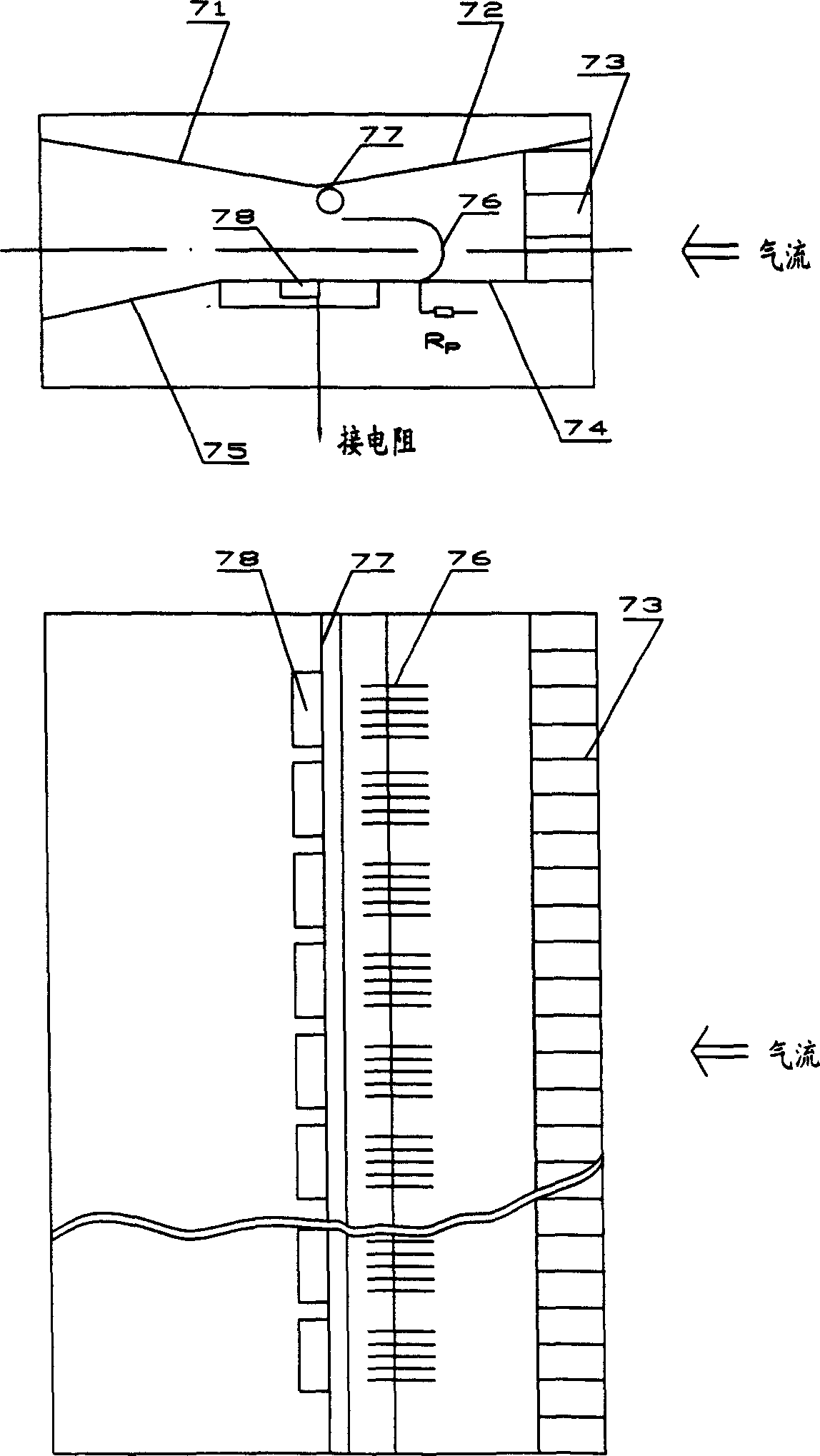

[0019] see first figure 1 and figure 2 , figure 1 is a schematic diagram of the laser structure of the embodiment of the present invention, figure 2 It is a structural schematic diagram of the gas discharge chamber of the present invention. As can be seen from the figure, the high-efficiency low-order mode CO of the present invention 2 The laser is composed of a laser head 1, a high-power switching power supply 2, a resistance box 3 and an air extraction system 4 placed in a box, the laser head 1 is placed above the box, the switching power supply 2, the resistance box 3 and air extraction system 4 are respectively placed in the lower part of the box, and the laser head 1 is composed of a centrifugal fan 5, an air duct 6, a discharge chamber 7, a heat exchanger 8, an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com