Mortar spraying robot for building

A technology for spraying robots and construction sand, which is applied in construction, building construction, etc. It can solve the problems of blocked pipes, prolonging the construction period, and inconvenient mixing, and achieves the effects of increasing pressure, reducing the number of blockages, and reducing blockages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

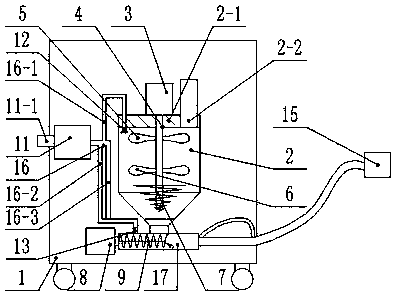

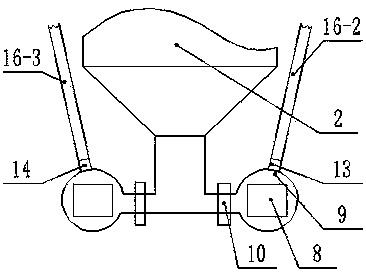

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] Such as figure 1 , figure 2 As shown, a mortar spraying robot for construction includes a cart 1 body, a hopper 2 is fixed inside the cart 1, a cover 2-1 is fixed on the upper end of the hopper 2, and a cover 2-1 is provided with The feed port 2-2, the upper middle part of the cover 2-1 is equipped with a motor A3 with a rotating shaft down, the motor shaft of the motor A3 passes through the cover 2-1 and is connected with the shaft 4, on the shaft 4 The fan blade A5 is fixed on the side close to the cover 2-1, the fan blade B6 is fixed on the side of the shaft 4, the fan blade B6 is located below the fan blade A5, and the bottom end of the shaft 4 is fixed with a tapered auger 7. A nozzle A12 is fixed on the bottom of the cover 2-1, and the nozzle A12 is connected to the water pipe A16-1, the water pipe A16-1, the water pipe B16-2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com