Triaxial wireless inclinometer verification rack and use method for same

A technology of wireless while drilling and inclinometer, which is applied in the directions of surveying, earthwork drilling and production, borehole/well parts, etc. Poor problems, to achieve the effect of easy installation and enhanced clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

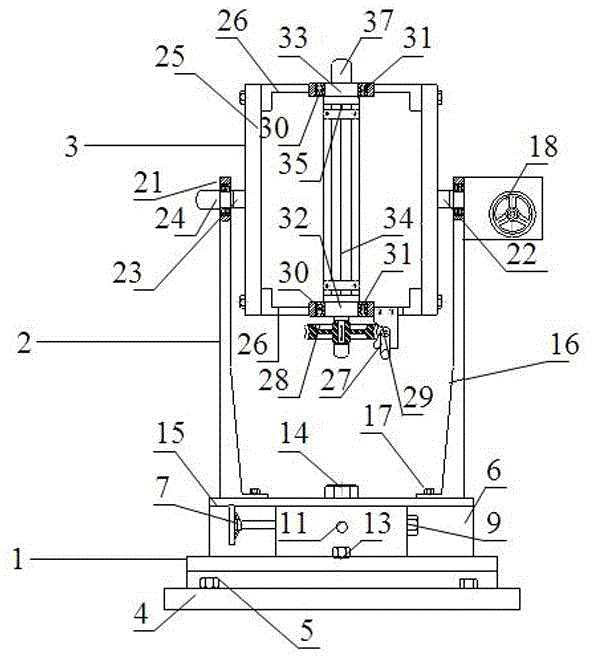

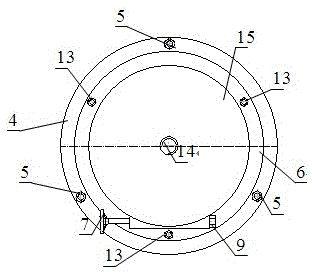

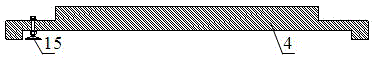

[0024] combined with Figure 1-6 , to further describe the present invention:

[0025] A three-axis wireless inclinometer calibration stand mentioned in the present invention includes an azimuth adjustment base 1, a well inclination adjustment bracket 2 and a tool face angle adjustment clamping device 3, on which the azimuth adjustment base 1 The well inclination adjustment bracket 2 is installed, and the well inclination adjustment bracket 2 is installed with the tool face angle adjustment clamping device 3 through the connecting frame, and the well inclination angle is adjusted by the rotation of the connecting frame. The azimuth adjustment base 1 mainly includes Support base 4, leveling feet 5, angle adjustment base 6, first runner 7, first worm wheel 8, first worm 9, azimuth non-magnetic photoelectric encoder 10, lead hole 11, ball slideway 12, base connecting bolts 13. The base shaft 14 and the turntable 15, the support base 4 is equipped with a leveling foot 5, by adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com