Gray combined modeling and optimized vibration controlling method of large intelligent draught fan blade system

A wind turbine blade and vibration control technology, which is applied in the control of wind turbines, wind turbine components, wind turbines, etc. Power generation efficiency, not considering various uncertain factors, etc., to achieve the effect of improving uncertainty modeling, overcoming uncertainty interference, and ensuring safe and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

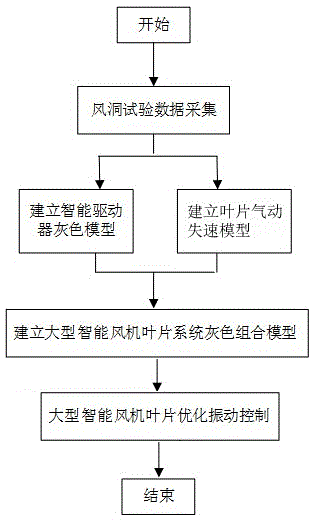

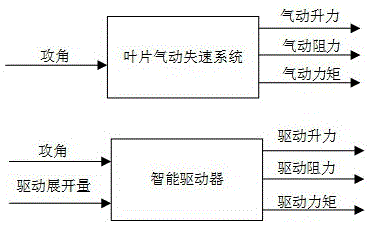

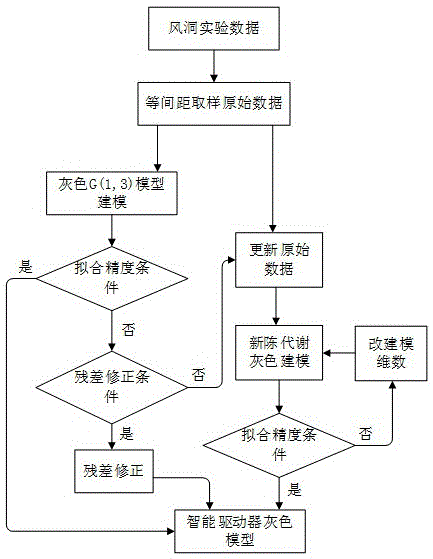

[0031] see figure 1 , the method sequence of the present invention comprises the following steps: (1) wind tunnel experiment data acquisition; (2) establish respectively intelligent driver gray model and blade aerodynamic stall model; (3) establish large-scale intelligent fan blade gray combination model; (4) large-scale Smart fan blades optimize vibration control.

[0032] Each step is described in detail as follows:

[0033] 1. Wind tunnel experiment data collection

[0034] Although the aerodynamic stall principle of wind turbine blades is basically the same, with the enlargement of wind turbines, due to the development of blade materials and the diversification of blade airfoils, fan blades based on different materials and different airfoils have different aerodynamic characteristics and elastic properties. The modeling of large-scale intelligent wind turbine b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com