Centrifugal fan

A technology of centrifugal fans and main boards, applied in non-variable pumps, non-displacement pumps, radial flow pumps, etc., can solve problems such as increased noise, reduced fan efficiency, and uneven airflow, so as to improve efficiency, Noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

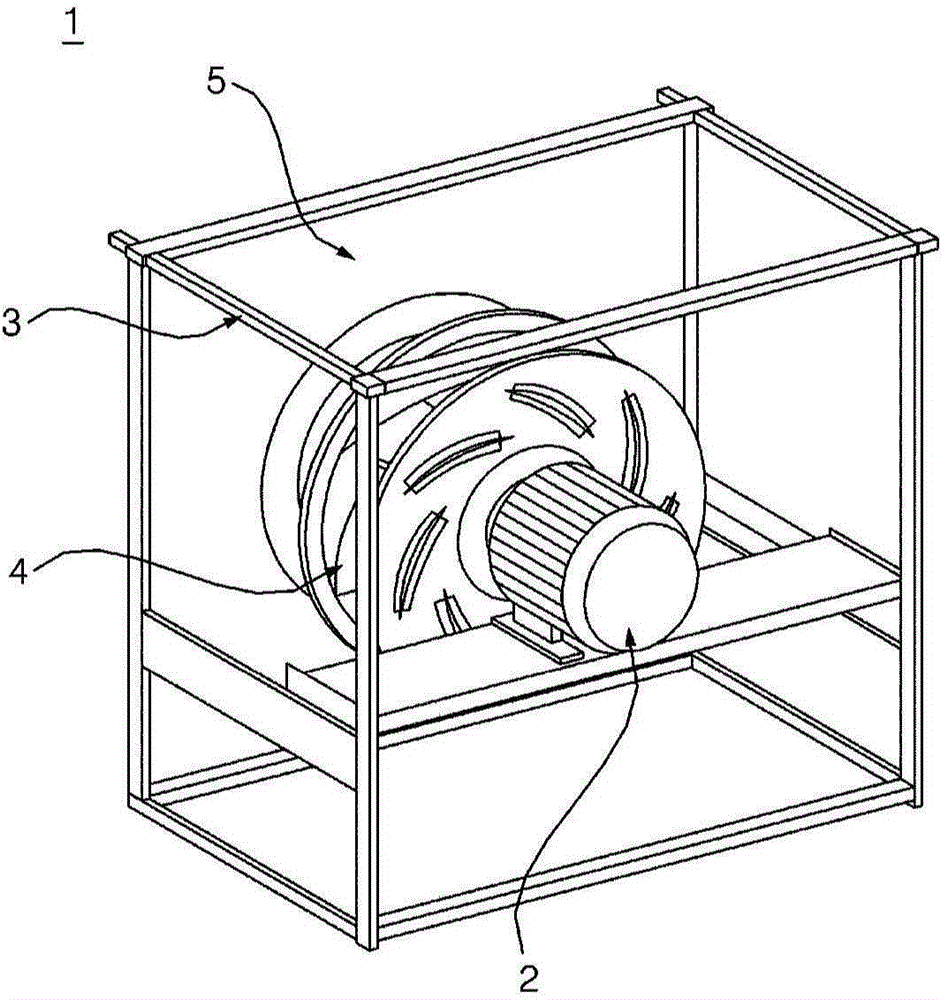

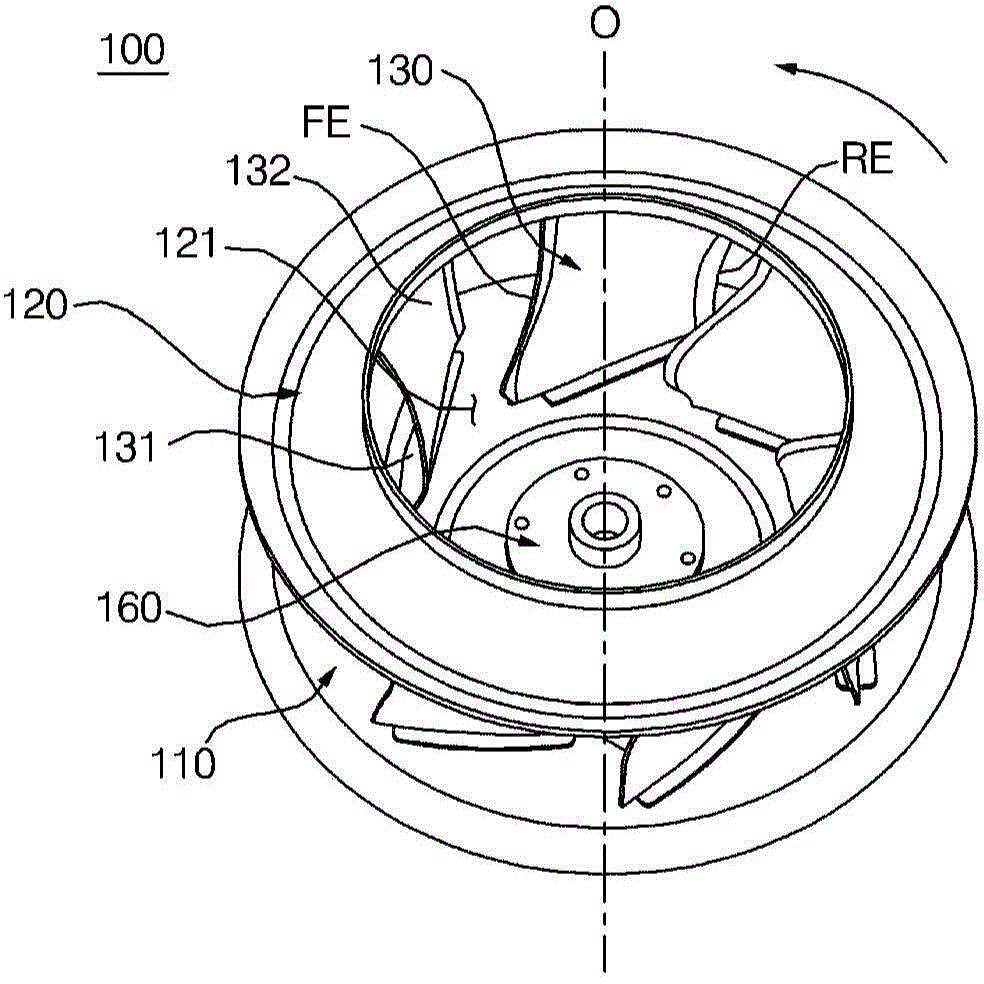

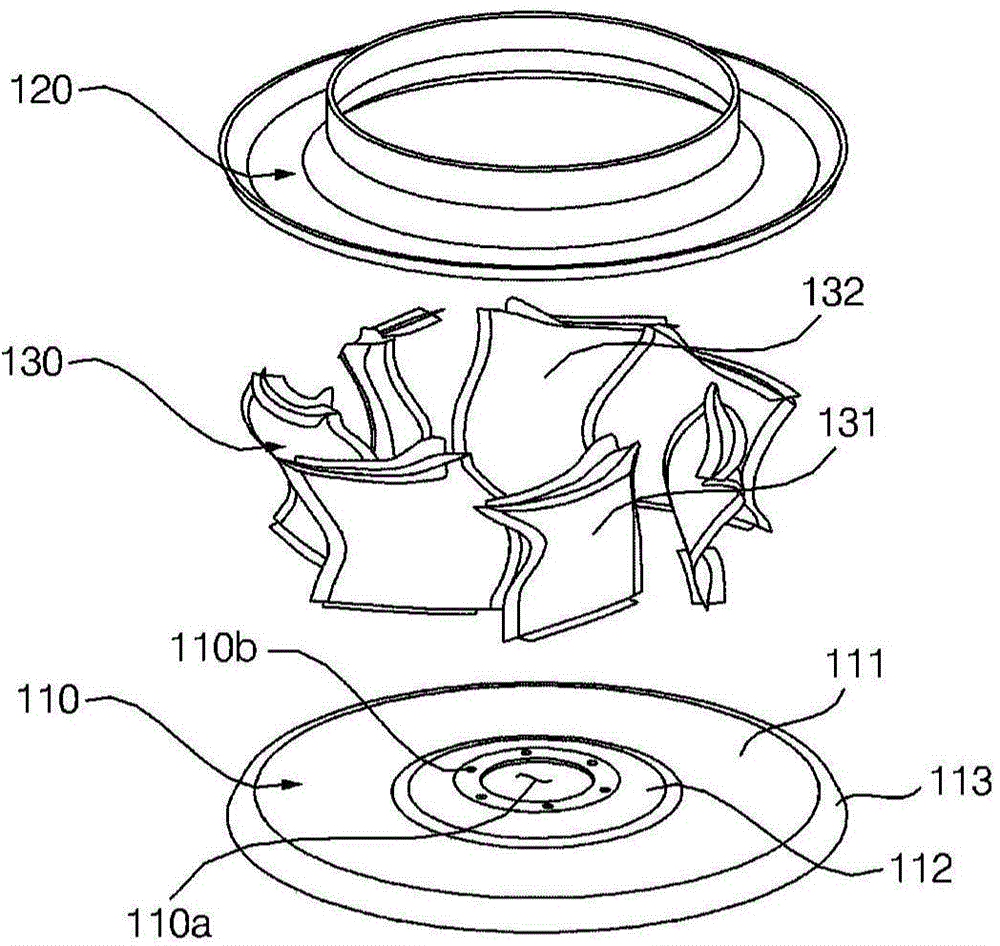

[0028] figure 1 A figure showing a plug-in fan module as an example of an applicable centrifugal fan. The centrifugal fans of the embodiments described below can be applied to refrigerators, air conditioners, vacuum cleaners, and the like. Since the air naturally flows into the inside of the fan and then is discharged outside, the above-mentioned centrifugal fan can be installed without a duct. Such as figure 1 The shown plug-in (plug) fan module 1 is suitable for an air conditioner, and the centrifugal fan in one embodiment of the present invention is suitable for a plug-in (plug) fan module 1. The air is cooled or heated and resupplied into the room.

[0029] The fan module 1 may include a motor 2 having a rotation shaft, a support frame 3 supporting the motor 2 , and a centrifugal fan 4 combined with the rotation shaft of the motor 2 . In addition, an opening through which air can flow into the centrifugal fan 4 is formed on the front panel 5 provided on the front surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com