Compaction groove screw for Halfen channel, support structure and mounting method

A technology of supporting structure and pressing groove, applied in the direction of screws, connecting members, threaded fasteners, etc., can solve the problems of troublesome installation, inability to adjust, difficult to operate, etc., and achieve the effect of easy inspection, easy operation, and short installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

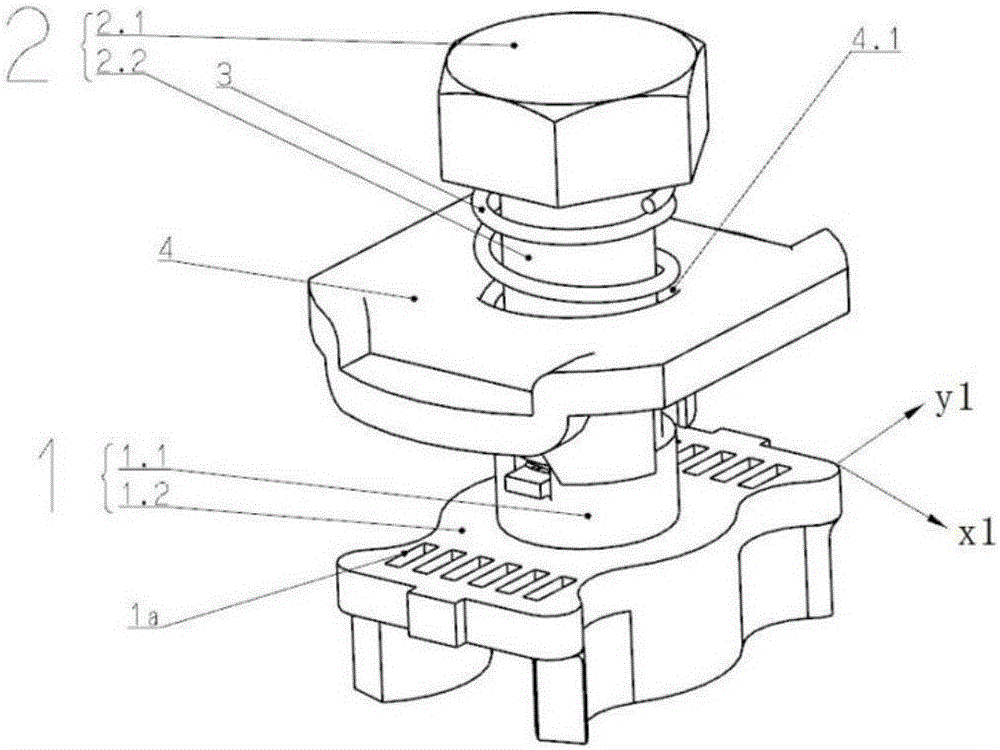

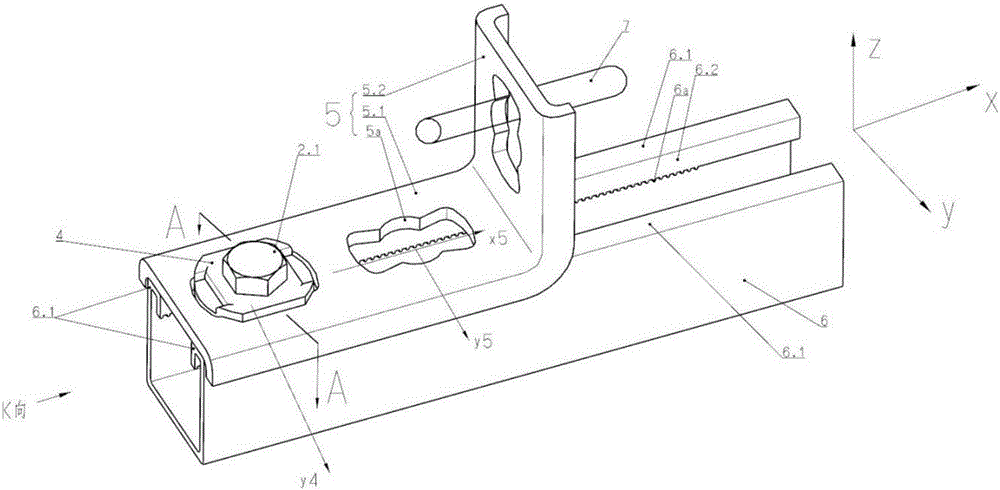

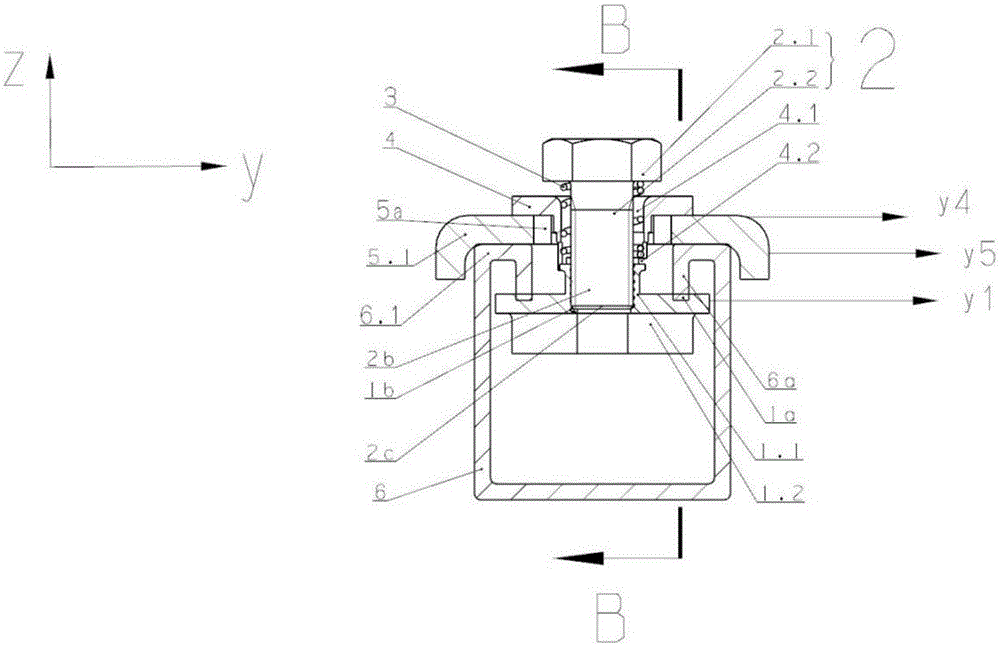

[0024] The pressing slot nail for the Hafen channel in this embodiment includes the following features:

[0025] 1) see figure 1 , The upper end of the channel nut 1 is a thin cylinder 1.1, and the lower end is a groove base 1.2. There is a row of rectangular slots at both ends of the slot pedestal along the horizontal direction Y1. See Figure 4 , a row of rectangular slots is 6 rectangular slots 1a arranged along the axis X. And a row of rectangular grooves can be plugged and matched with any 6 teeth of the several teeth 6a of the Hafen groove 6 along the X direction. See image 3 , The center of the thin cylinder 1.1 and the groove base 1.2 is an internal screw hole 1b through.

[0026] 2) see figure 1 , image 3 , The bolt 2 is composed of a bolt head 2.1 and a bolt screw rod 2.2. See image 3 , the external thread 2b of the bolt screw 2.2 meshes with the inner screw hole 1b of the channel nut, the bolt screw is screwed into the inner screw hole, and the bottommos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com