Damping device for large machine tool

A technology of shock absorption device and machine tool, which is applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of unsatisfactory shock absorption effect and ground damage of machine tools, and achieves simple structure, reduced shaking, and effective significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

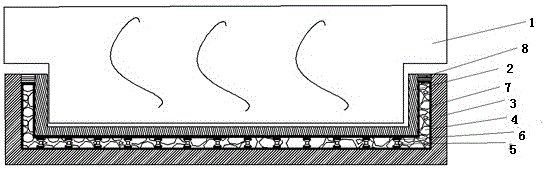

[0027] Such as figure 1 As shown, a large-scale machine tool shock absorbing device is used for the connection between a large machine tool and the ground, and it includes a machine tool support frame 2 and a ground support frame 3. The machine tool support frame 2 is arranged inside the ground support frame 3, and the machine tool A machine tool 1 is placed inside the supporting frame, and an intermediate layer 4 is arranged between the supporting frame 2 of the machine tool and the supporting frame 3 on the ground. Several supporting seats 5 are arranged in the intermediate layer 4, and the top of the supporting seat 5 and the supporting frame 2 of the machine tool A shock-absorbing spring 6 is arranged between them, and a shock-absorbing spring 6 is arranged between the bottom of the support seat 5 and the ground support frame 3; the middle layer 4 is filled with foamed aluminum material.

Embodiment 2

[0029] In order to further strengthen the stability of the machine tool support frame 2 and the ground support frame 3, the scheme is as follows:

[0030] Such as figure 1 As shown, a large-scale machine tool shock absorbing device is used for the connection between a large machine tool and the ground, and it includes a machine tool support frame 2 and a ground support frame 3. The machine tool support frame is arranged inside the ground support frame, and the machine tool support frame A machine tool 1 is placed inside, an intermediate layer 4 is formed between the machine tool support frame 2 and the ground support frame 3, and a plurality of support seats 5 are arranged at the bottom of the intermediate layer 4, and the plurality of support seats 5 are arranged in a matrix in the intermediate layer. For arrangement, a damping spring 6 is arranged between the top of the support base 5 and the machine tool support frame 2, and a damping spring 6 is provided between the bottom...

Embodiment 3

[0032] In order to increase the damping effect and sealing performance, the present invention makes the following improvements:

[0033] Such as figure 1 As shown, a large-scale machine tool shock absorbing device is used for the connection between a large machine tool and the ground, and it includes a machine tool support frame 2 and a ground support frame 3. The machine tool support frame is arranged inside the ground support frame, and the machine tool support frame A machine tool 1 is placed inside, an intermediate layer 4 is formed between the machine tool support frame 2 and the ground support frame 3, a number of support seats 5 are provided at the bottom of the intermediate layer 4, and a number of support seats 5 are provided between the top of the support seat 5 and the machine tool support frame 2 Damping spring 6, a damping spring 6 is arranged between the bottom of the support base 5 and the ground support frame 3; the middle layer 4 is filled with foamed aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com