Fireproof structure allowing pipeline to penetrate lightgage steel joist gypsum board partition wall and construction method of fireproof structure

A light steel keel, fireproof structure technology, applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of fire resistance time limit safety hidden danger, the hole sealing can not be achieved, save fire sealant, solve the problem Non-plasticity, the effect of improving the fire resistance time limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

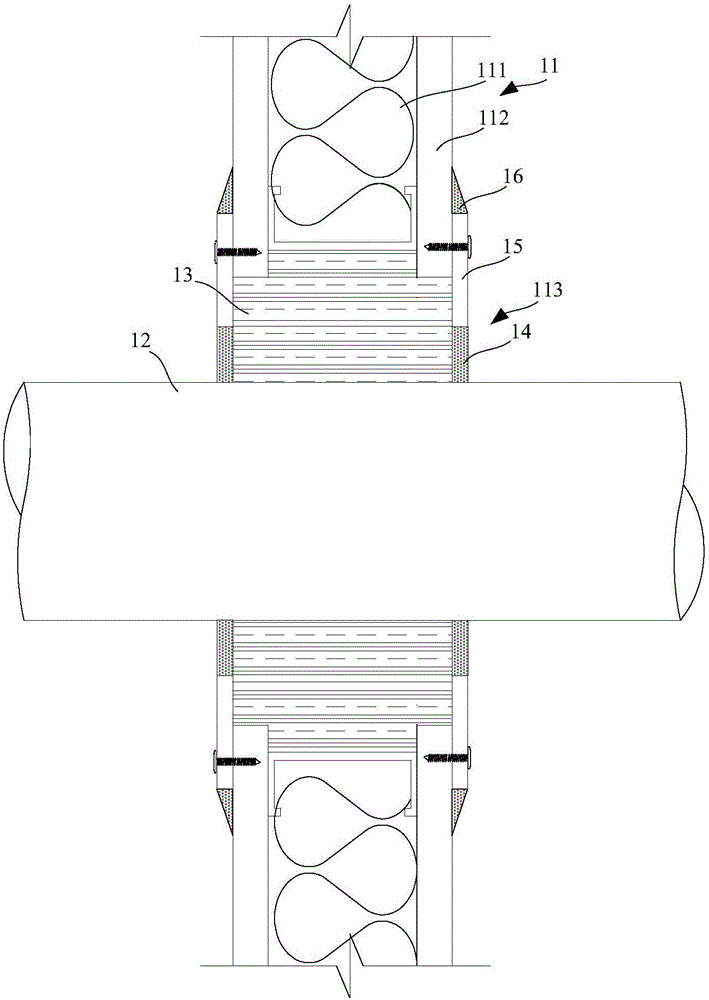

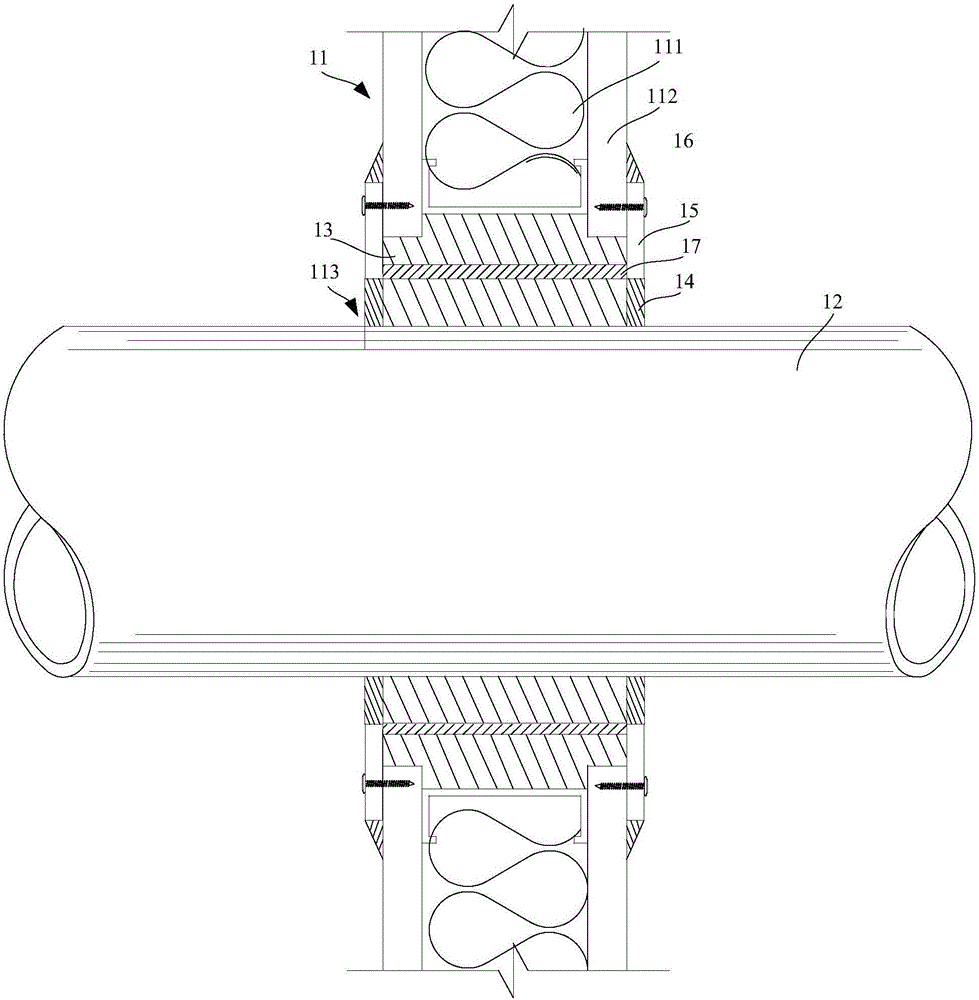

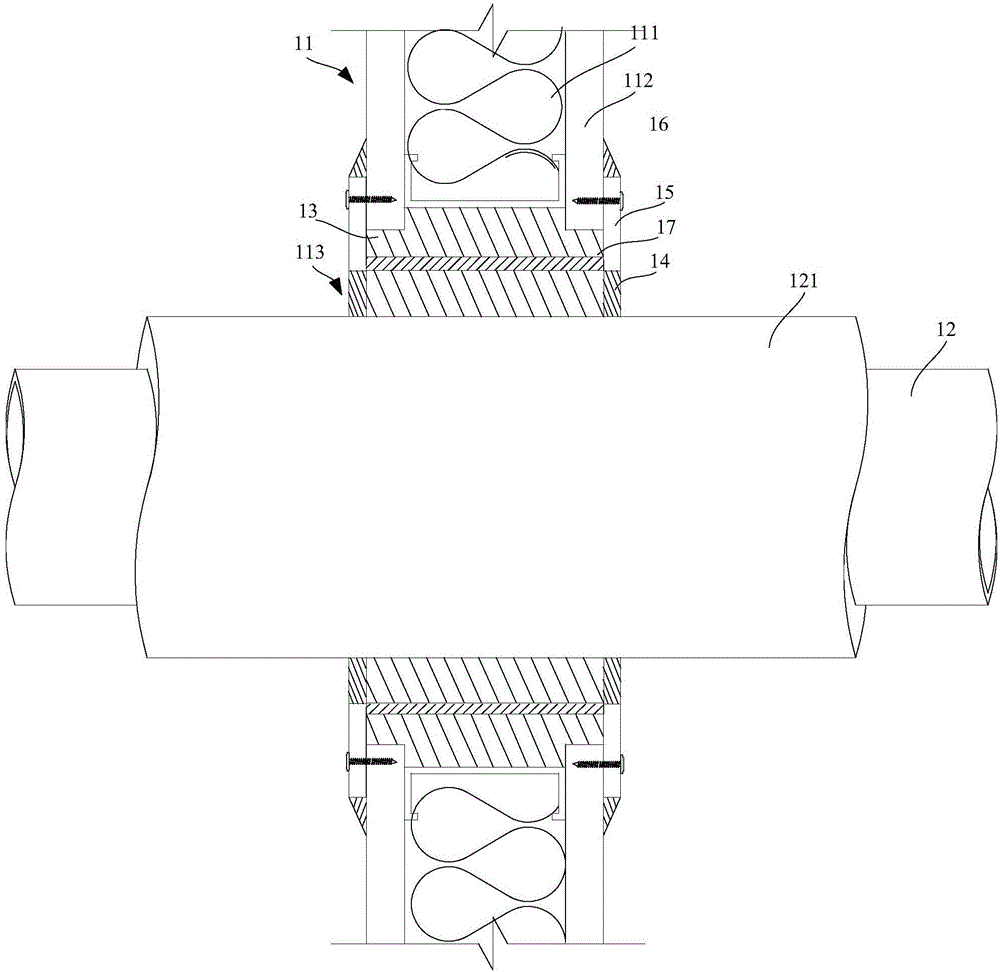

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] The invention provides a fireproof structure and construction method for pipelines passing through light steel keel gypsum board partition walls. The openings on the steel keel gypsum board partition wall are optimized and treated to solve the problem of difficult sealing caused by the non-plasticity of the opening on the light steel keel gypsum board partition wall. Rock wool is used to fill the opening of the gypsum board partition wall for fire protection. To make it meet the requirements of the fire resistance time limit, use gypsum board and fireproof sealant to seal the opening, further improve the fire performance of the gypsum board partition wall, and make the opening of the opening dense and the structural strength firm and stable. The fireproof structure and construction method of the pipeline passing through the light steel k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com