High pole plumb bob

A technology of wire hammer and high rod, which is applied in the direction of plumb line, ship parts, ships, etc., can solve the problems of troublesome use, long time-consuming use, and labor-intensive use, so as to achieve convenient use, less manpower consumption, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

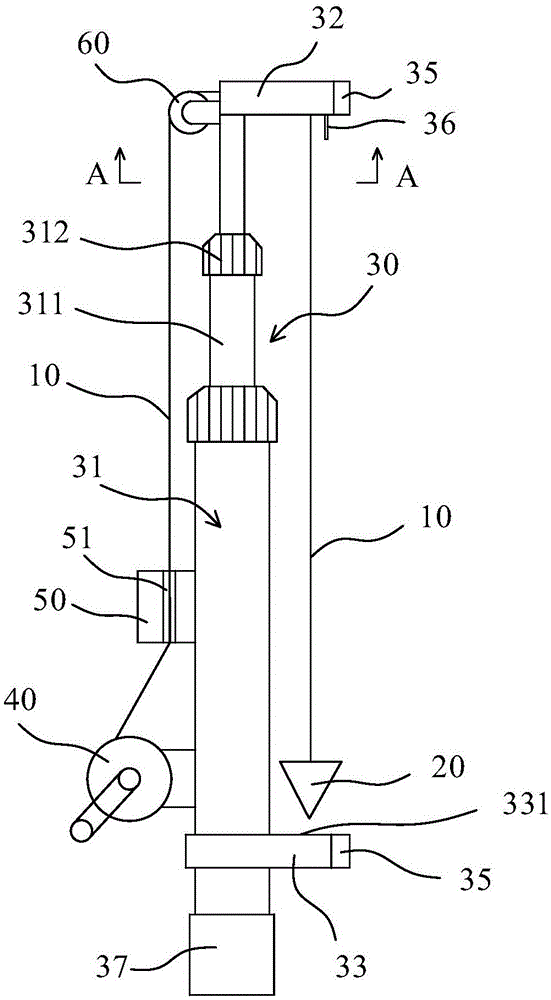

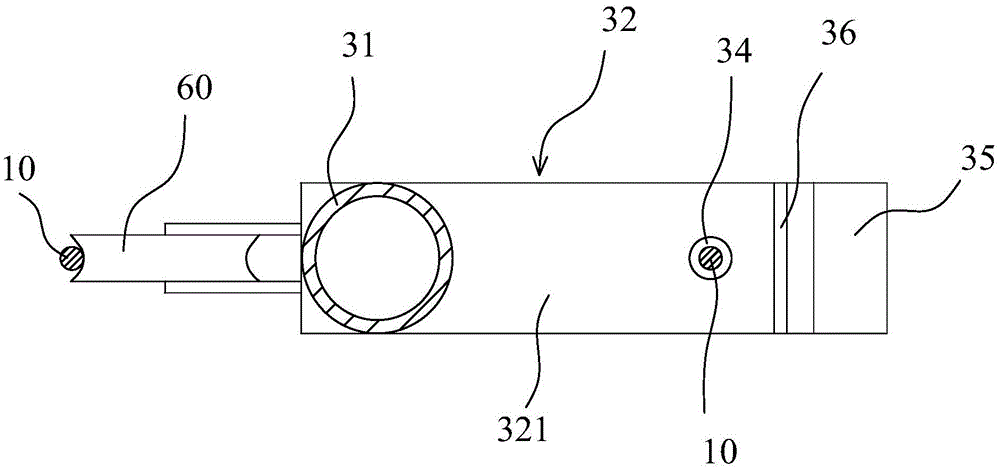

[0018] Such as figure 1 and figure 2 As shown, a high pole line hammer includes a steel wire rope 10, a hammer head 20, and a rod body 30. The rod body 30 includes a longitudinal part 31, a first transverse part 32 and a second transverse part 33, and the first transverse part 32 is vertical Affixed to one end of the longitudinal component 31, the second transverse component 33 is vertically fixed to the middle of the longitudinal component 31; the first transverse component 32 is provided with a through hole 34; the longitudinal component 31 is also fixed to a wire receiver 40, a cable arrangement 50. Pulley assembly 60; one end of the wire rope 10 is fixedly connected to the wire take-up 40, and the other end is fixedly connected to the hammer head 20; the part of the wire rope between the wire take-up 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com