Method for preparing TEM chip sample

A chip and sample technology, which is applied in the field of preparing TEM chip samples, can solve problems such as easy oxidation, observation errors, and easy change of growth appearance, so as to prevent oxidation and corrosion and improve the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Please refer to Figure 6 , and combined with Figure 3 to Figure 5 , in order to achieve the above object, the present invention provides a kind of preparation TEM chip sample method, comprises the following steps:

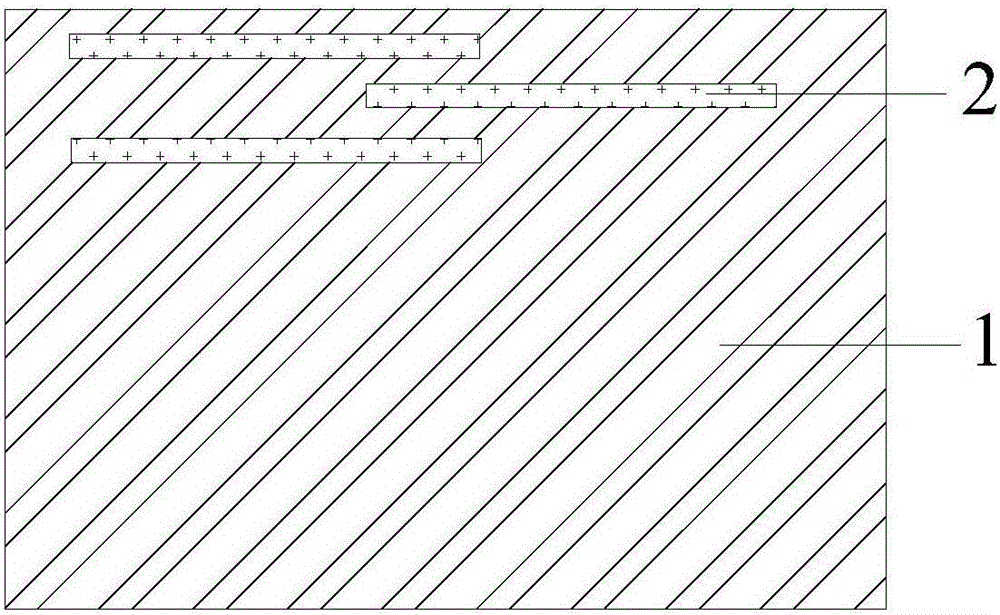

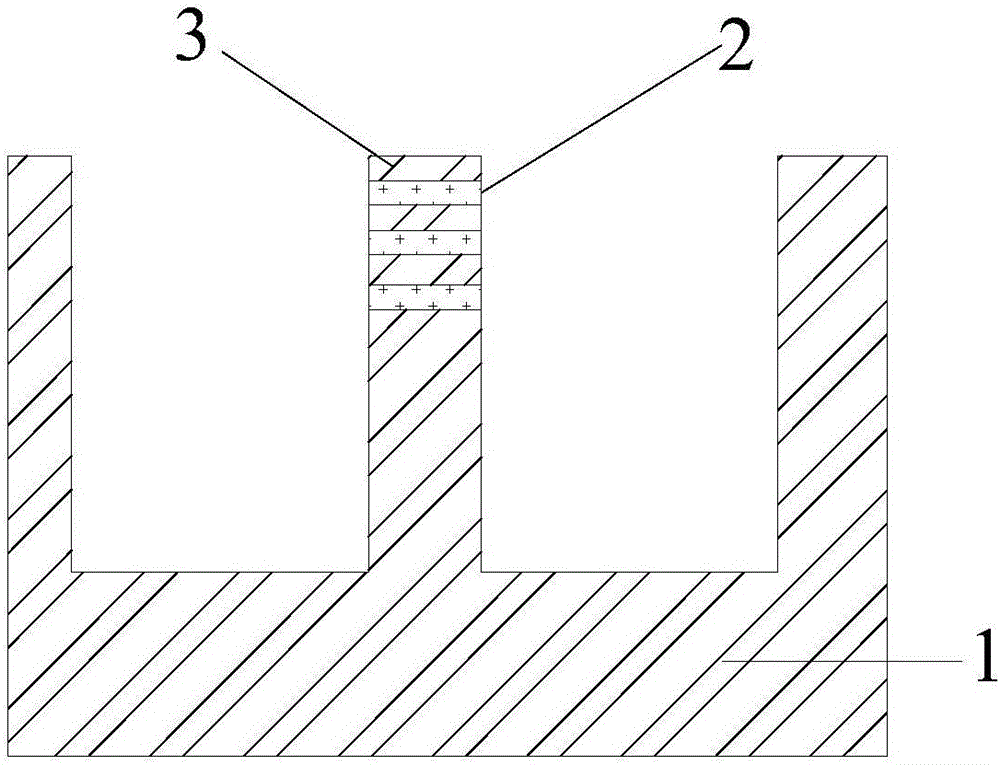

[0033] Step 1: providing a chip 10 containing a metal circuit 20;

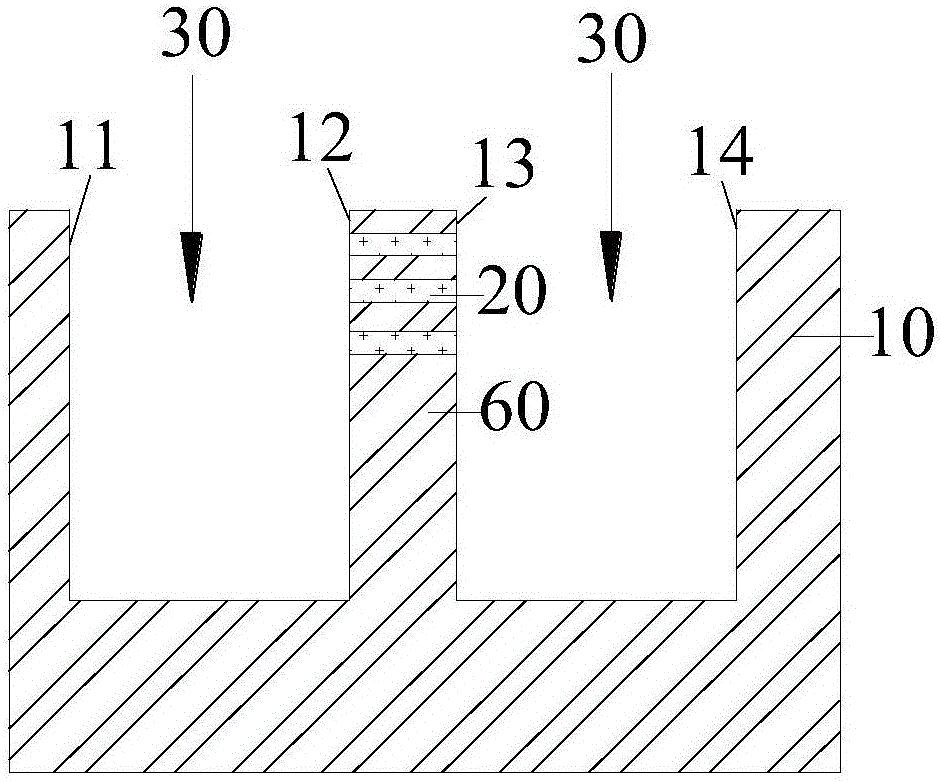

[0034] Step 2: Please refer to image 3 , use the focused ion beam 30 to cut the chip 10 containing the metal circuit 20, preferably, adjust the current intensity of the ion gun used to emit the focused ion beam 30 to 100pA~7000pA, use the focused ion beam 30 to cut the chip 10 in the middle part of the chip 10 Two grooves are cut out to expose the sample sheet 60 that needs to be observed in the middle. The inner walls of the two grooves form the first surface 11, the second surface 12, the third surface 13, and the fourth surface 14 in turn. These four The surfaces are parallel to each other, and metal circuits 20 are exposed on the second surface 12 and the third surface 13. Generall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com