High-speed strip steel surface image acquiring and image processing apparatus and method thereof

An image processing device and surface image technology, which is applied to closed-circuit television systems, optical testing flaws/defects, etc., can solve the problem of not retrieving the image processing device, etc., and achieve real-time image processing and reduce stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

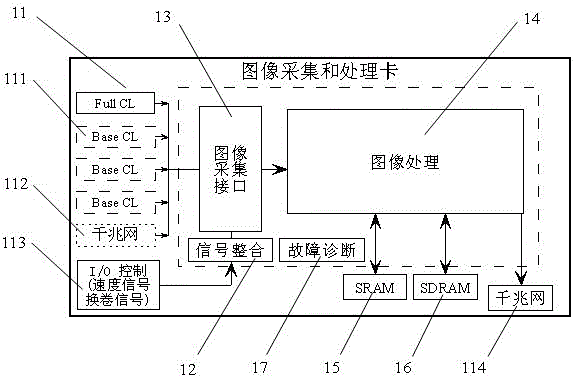

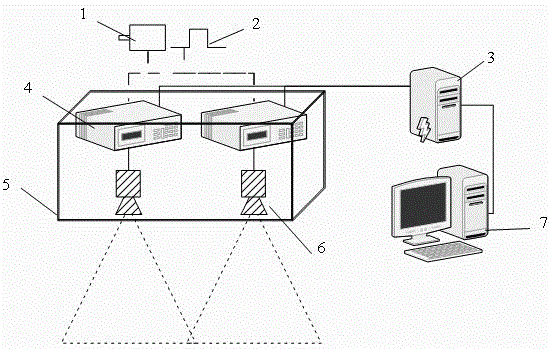

[0029] see figure 1 , a high-speed steel strip surface image acquisition and image processing device, comprising: an input and output interface module 11, a speed signal integration module 12, an image acquisition interface module 13 and an image processing module 14;

[0030] The input and output interface module 11 includes: first, four standard CamLink interfaces 111 or a standard Gigabit network interface 112 are configured to realize the connection with the image sensor and realize the transmission of image data and image acquisition control signals. The image sensor in this article mainly refers to the camera, and the two can be used in common. Second, configure the I / O interface 113 to realize the connection with the on-site production signal, receive the production speed signal and the steel coil splitting signal, and transmit the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com