Suction-type cleaner with dedusting control for the filter or the filters

A technology for cleaning positions and vacuum cleaners. It is applied to devices for cleaning filters, vacuum cleaners, cleaning equipment, etc. It can solve the problem of consuming extra force and achieve the effects of small driving power, reliable jitter, and small current demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

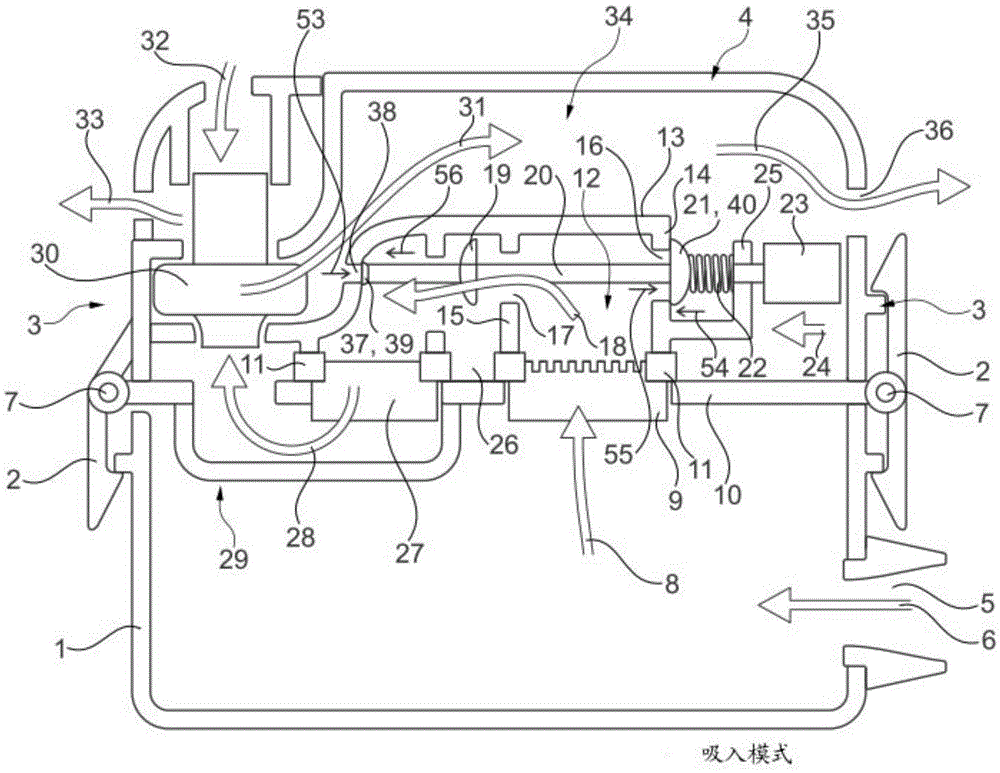

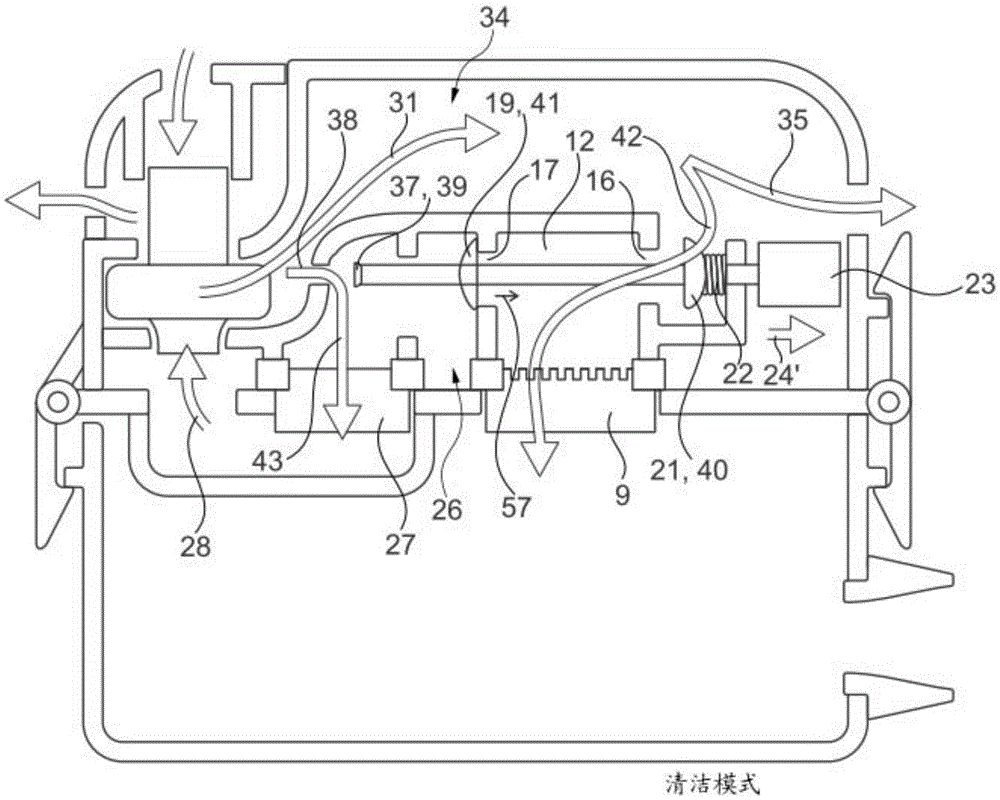

[0038] exist figure 1 A vacuum cleaner is generally shown in FIG. 2 , which is composed of a main filter 27 and an upstream pre-filter 9 . However, the present invention is not limited thereto. It can likewise have two main filters 27, which are then correspondingly associated with a cleaning unit, as it is in the form of cleaning unit 3 figure 1 as shown in.

[0039] Therefore, according to the present invention figure 1 and 2 The cleaning device can also be transferred to the double filter device according to DE 10101219 A1.

[0040] Accordingly, the invention is not restricted to cleaning a single main filter 27 .

[0041] In the exemplary embodiment shown, the vacuum cleaner essentially consists of a dust-containing container 1 which is detachably connected via a lateral cover 2 to a cleaning unit 3 arranged thereon. A cover unit 4 is detachably arranged on the cleaning unit 3 .

[0042] Contaminated air flows in the direction of the arrow 6 via the inlet 5 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com