A Negative Pressure Feedback Suction Ejector Type Dispensing Valve

A thimble-type, glue-dispensing valve technology, which is applied to coatings, devices that apply liquid to the surface, etc., can solve the problems of air bubbles or vacuum packs, poor glue breaking performance, etc., and achieve smooth and continuous glue dispensing. The effect of improving stability, ensuring accuracy and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

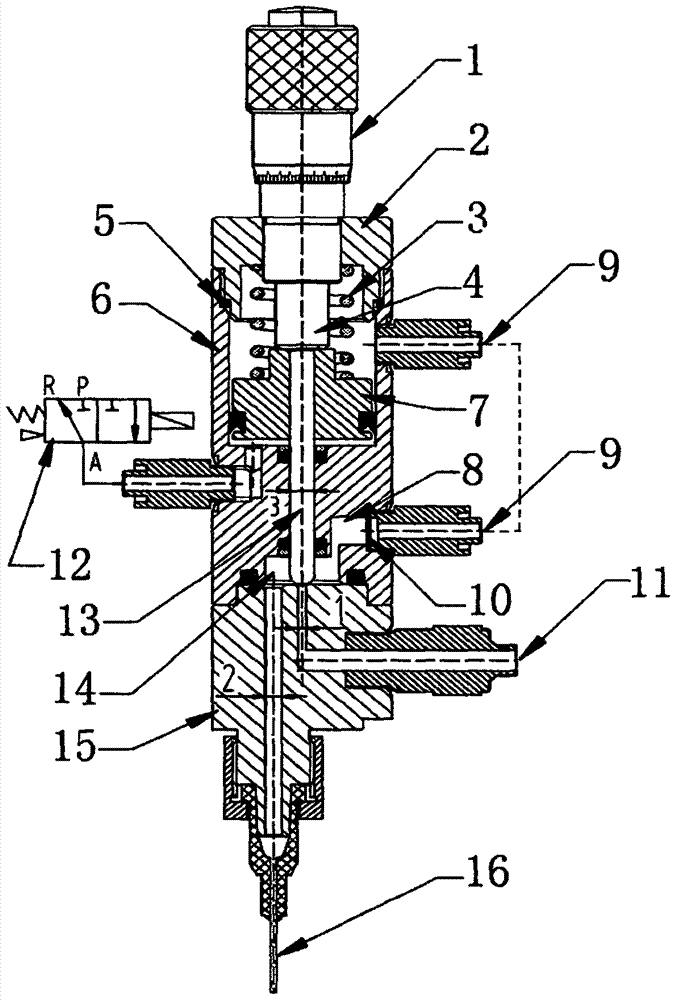

[0020] In conjunction with the accompanying drawings, the present invention will be described in further detail.

[0021] As shown in the figure, a negative pressure feedback suction thimble type dispensing valve includes a micrometer gauge 1, an upper valve body 6, a lower valve body 15, a glue nozzle 16, a negative pressure connecting pipe 9, and a two-position three-way solenoid valve. Valve 12; the upper valve body 6 includes a spring cap 2, a compression spring 3, a limit block 4, a sealing ring 5, and a piston 7; the lower valve body 15 includes an air collection chamber 8, a diaphragm 10, a glue inlet 11, Needle valve 13, valve chamber 14;

[0022] The micrometer 1 is connected to the limit block 4; the limit block 4 is connected to the needle valve 13; the limit block 4 is connected to the piston 7; the needle valve 13 is connected to the The piston 7 moves up and down; the end of the needle valve 13 is a valve to control the amount of glue; the limit block 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com