Coater and its oven unit

A coating machine and oven technology, which is applied to the surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of uneven drying, many processing parts, waste of resources, etc., to reduce uneven drying , less processing parts, and the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

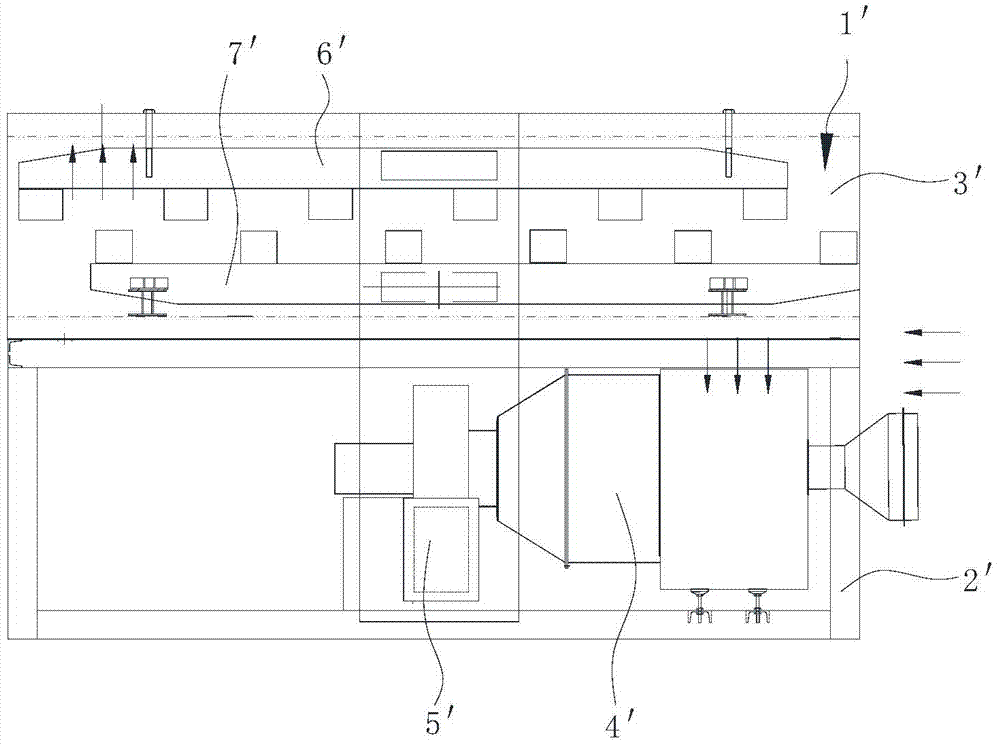

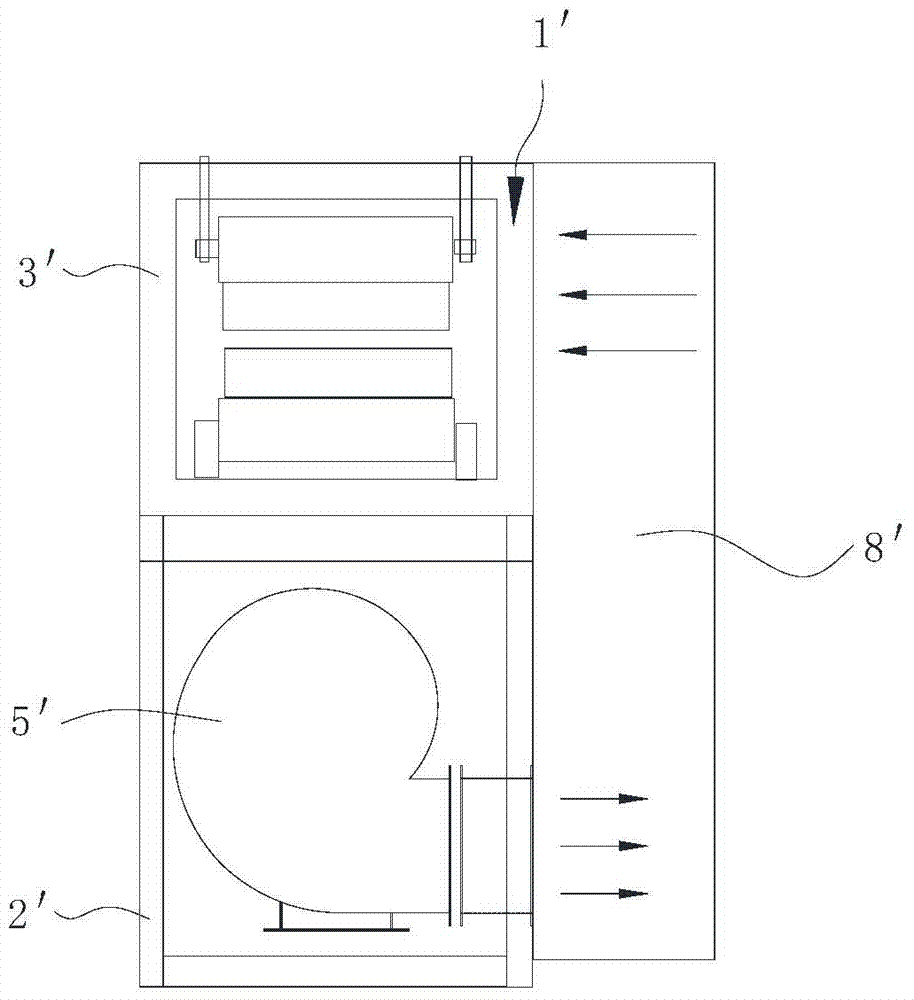

[0025] refer to Figure 4 to Figure 9 , the present embodiment provides a coating machine, especially an oven unit of the coating machine, the oven unit of the coating machine includes an integral frame with upper and lower layers.

[0026] The upper layer of the overall frame is provided with an upper wind chamber 5 and a lower wind chamber 6 extending along the length direction of the oven unit, and the inner diameters of the upper wind chamber 5 and the lower wind chamber 6 gradually narrow along the air supply direction, further, the upper wind chamber 5 and the lower wind chamber 6 The inner diameter may be constant along the air supply direction. Between the upper wind chamber 5 and the lower wind chamber 6 is the substrate transmission channel, and the upper wind chamber 5 and the lower wind chamber 6 can blow and dry the upper surface and the lower surface of the substrate respectively; further, the upper wind chamber 5 and the lower wind chamber 6 face the substrate ...

Embodiment 2

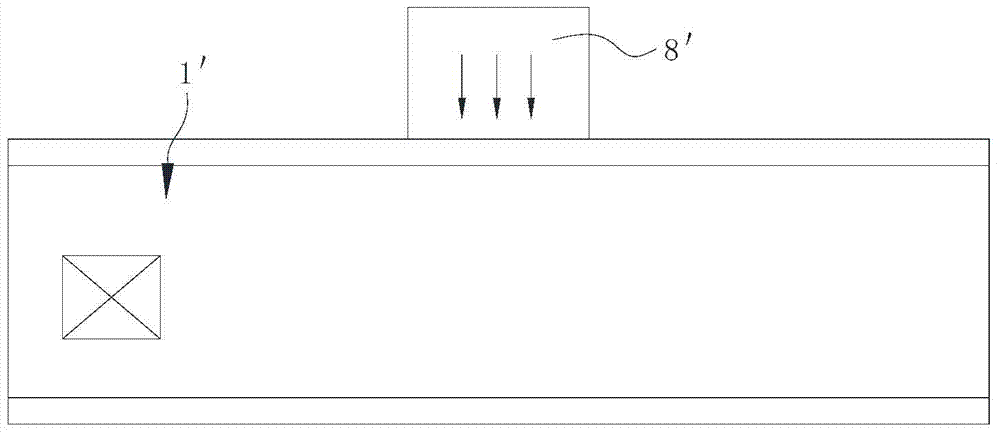

[0031] See Figure 10 , the difference between this embodiment and the first embodiment is that the oven unit can also be based on the first embodiment Figure 4 Symmetrical structure. That is to say, the circulation fan 4 and the static pressure box 8 can also be arranged on the other side of the overall frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com