Automobile door closure corner edge covering mechanism

A door cover and corner technology, applied in the field of car door cover corner wrapping mechanism, can solve the problems of rainwater penetration, sealant failure, etc., achieve the effect of large space distance, eliminate processing errors, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

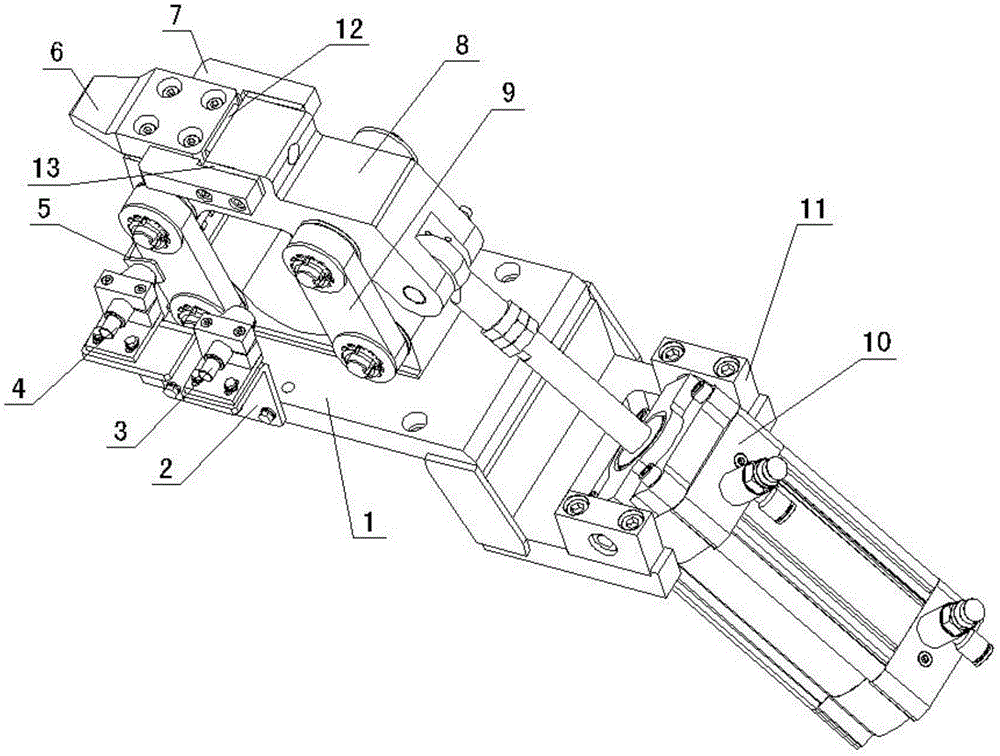

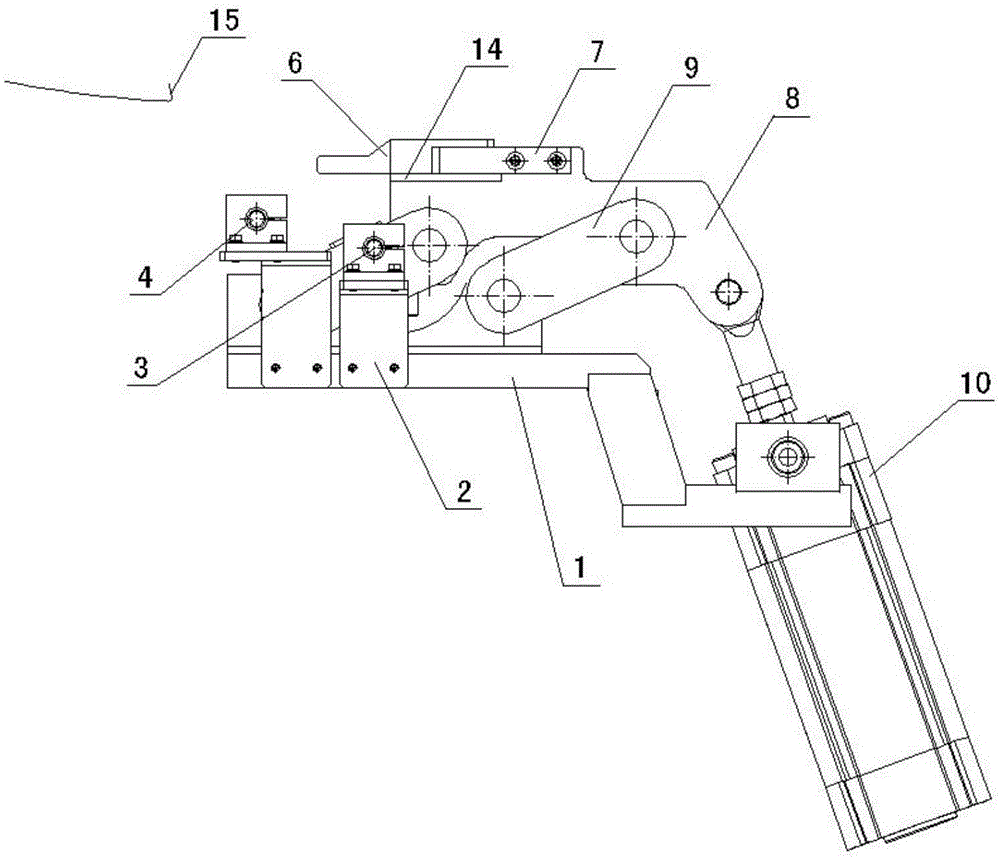

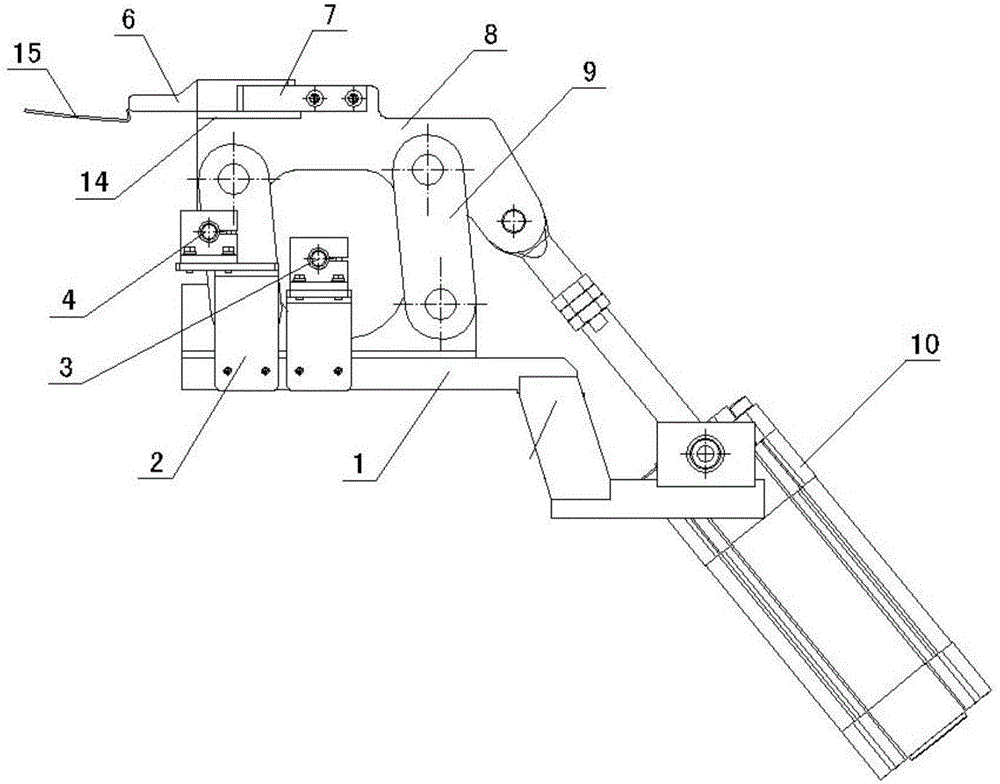

[0023] see figure 1 , the structure of the car door cover corner wrapping mechanism in the present embodiment is set to:

[0024] One end of the base 1 is set as a lower step surface, and trunnion support blocks 11 are respectively arranged on both sides of the lower step surface; the cylinder seat of the cylinder 10 is hinged on the trunnion support block 11 through a pin shaft, and can be wound around the trunnion The support block 11 swings to provide driving force;

[0025] The press knife 6 is fixedly installed on the front end surface of the press knife installation block 8 by bolts, and the tail of the press knife installation block 8 is hinged with the piston rod end of the cylinder 10 through a pin shaft; Angular digital model matching surface;

[0026] A parallel four-bar linkage mechanism is arranged symmetrically on both sides of the base 1, and the parallel four-bar linkage mechanism is composed of a pair of parallel connecting rods 9, a pressing knife mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com