Automatic hardware buffing device

An automatic polishing and hardware technology, applied in grinding/polishing safety devices, surface-polishing machine tools, grinding/polishing equipment, etc., can solve the problems of low production efficiency, poor applicability, environmental pollution, etc., to improve production efficiency , good polishing effect, comprehensive polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

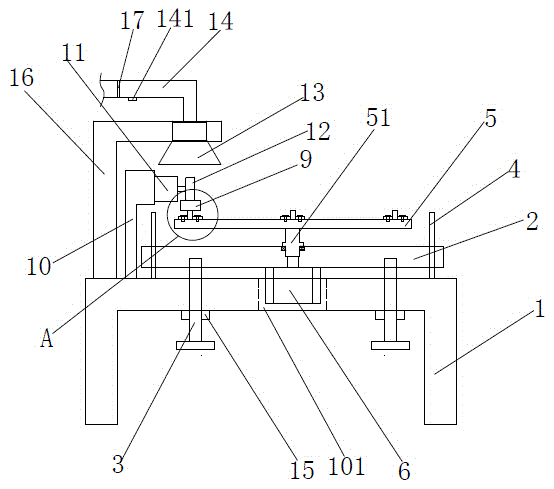

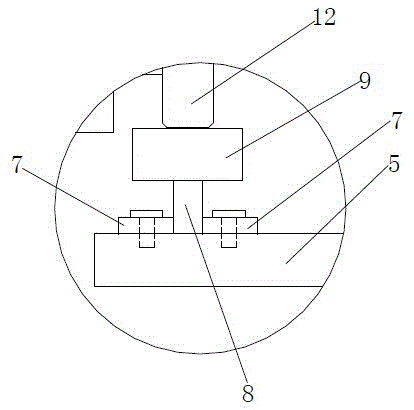

[0012] Such as figure 1 and figure 2 As shown, a hardware automatic polishing device includes a workbench 1, a bearing plate 2 is arranged above the workbench 1, an adjusting screw 3 is pierced on the workbench 1, and the upper part of the adjusting screw 3 is connected to the bearing plate 2, the workbench 1 is also provided with a guide column 4, the bearing plate 2 is slidingly connected with the guide column 4, a turntable 5 is arranged above the load plate 2, and the turntable 5 has a rotating shaft 51. The rotating shaft 51 of 5 passes through the bearing plate 2, and the first motor 6 is fixed under the bearing plate 2, and the first mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com