Wrench

A wrench and handle technology, applied in the field of wrenches, can solve the problems of difficulty in making tools, difficult functions, damage to the wrench, etc., and achieves the effects of simple structure, improved work efficiency, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

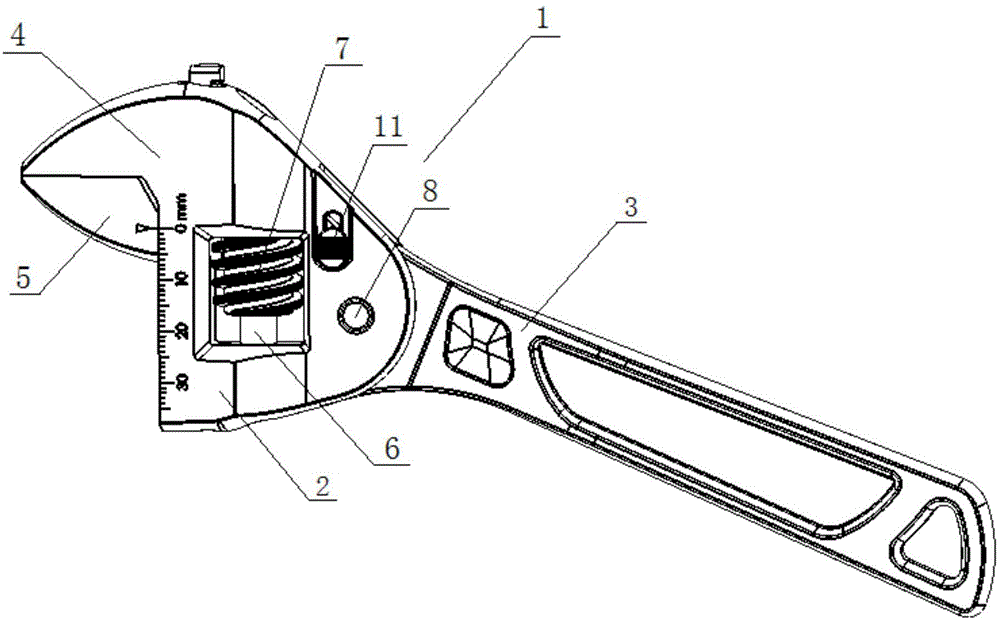

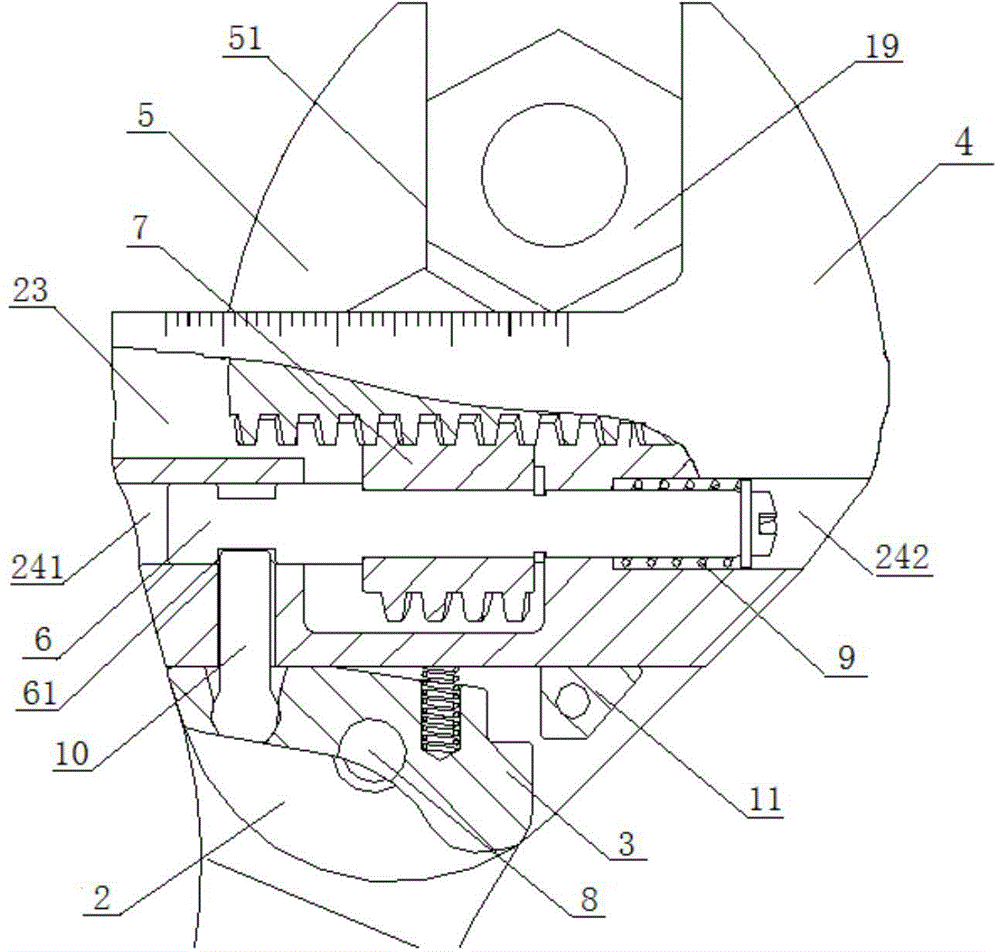

[0056] Such as figure 1 As shown, a wrench 1 according to an embodiment of the present invention includes: a body 2, a handle 3, a fixed wrench 4, a movable wrench 5 and a push rod 10;

[0057] The size of the handle 3 is designed to be suitable for the user to hold, and the handle 3 may include an injection molding sleeve to improve the comfort of holding.

[0058] The fixed wrench 4 is fixedly connected with the body 2 , and can also be integrally formed with the body 2 . In this embodiment, the fixed wrench 4 is integrally formed with the body 2 .

[0059] The body 2, the fixed wrench 4 and the movable wrench 5 can be made of cast steel or other high-strength materials.

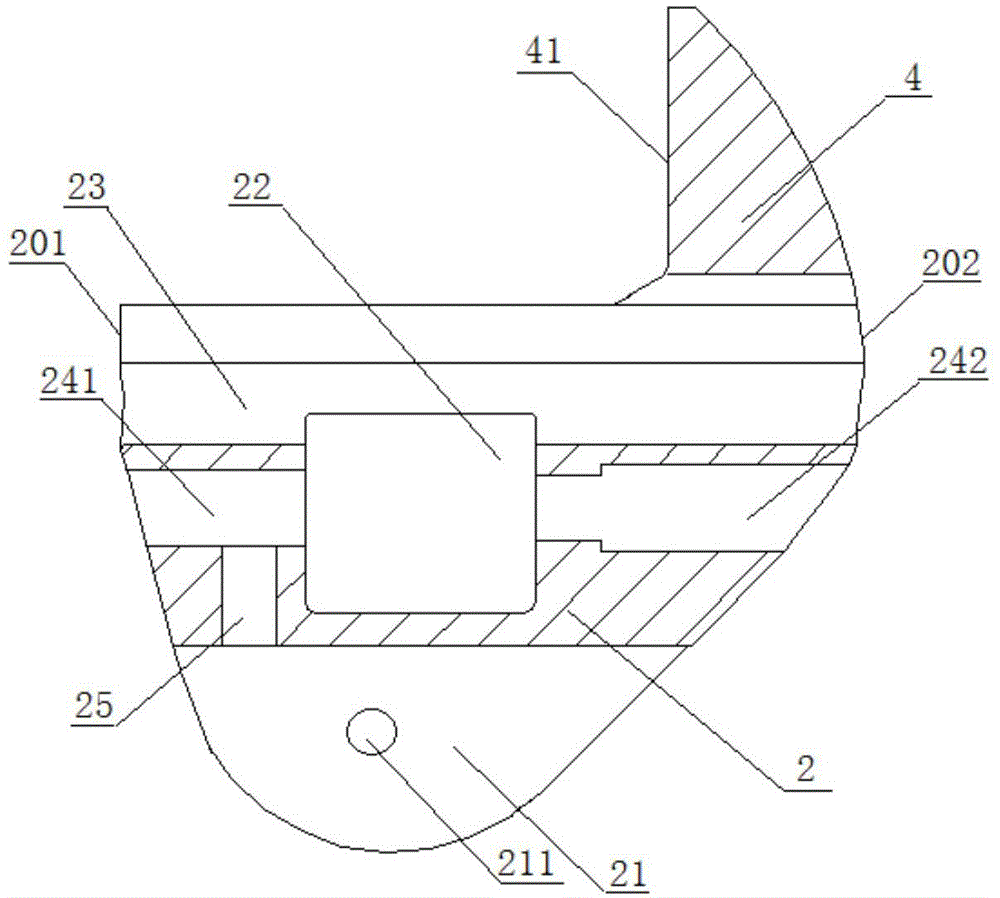

[0060] Such as figure 2 As shown, the fixed wrench 4 includes a wrench surface 41, and the wrench surface 41 contacts the workpiece when the wrench is operated. The workpiece mentioned here can include any device, component or fastener that the wrench 1 can hold. A typical workpiece is Fasteners that u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com