RTM forming process for hollow composite material products and forming mold used in RTM forming process

A composite material and molding process technology, applied in the field of RTM product molding, can solve the problems of difficult extraction, difficult extraction of the mandrel, and difficulty in controlling the expansion of the silicone mandrel, and achieve the effect of reducing production costs and operational difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

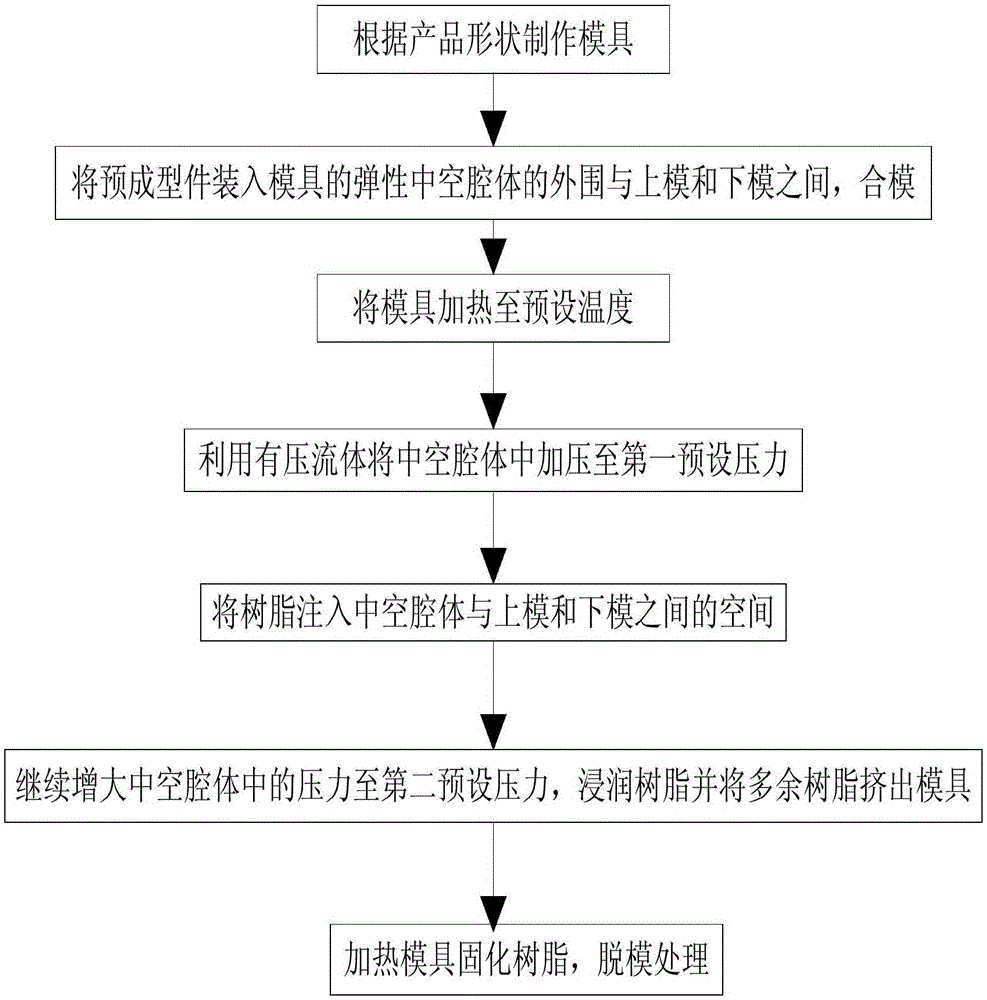

[0032] Example one:

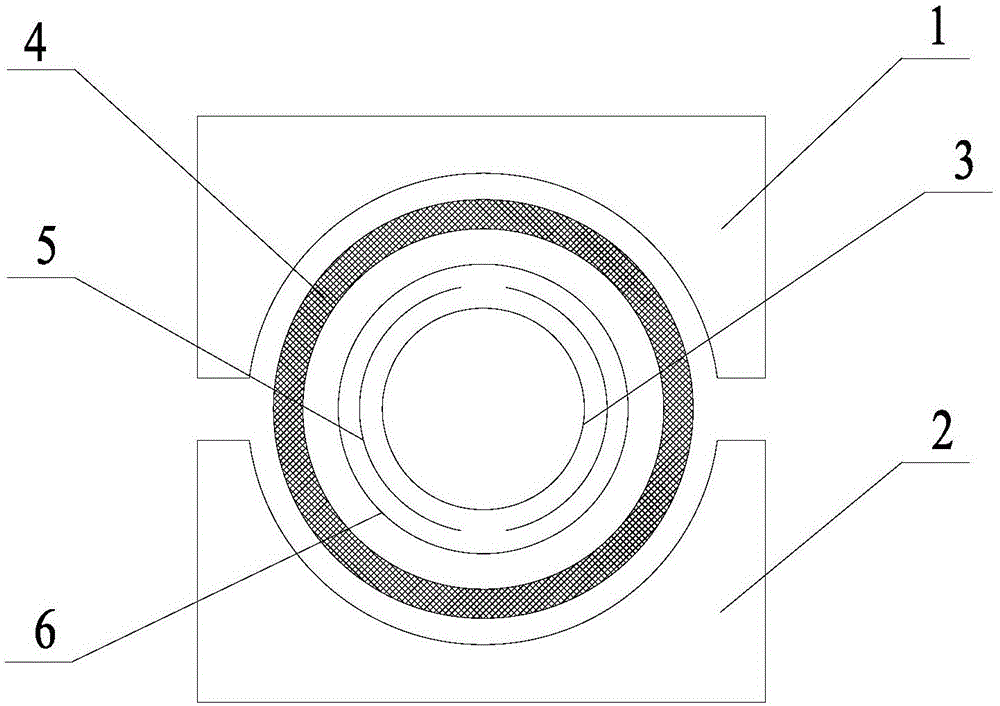

[0033] This embodiment provides an RTM molding process of a hollow composite product and a molding die used in the process. Such as figure 1 As shown, the forming mold includes an upper mold 1 and a lower mold 2, and also includes an elastic hollow cavity 3 provided between the upper mold 1 and the lower mold 2, and the hollow cavity 3 is provided with a pressure fluid inflow and Outlet fluid port. In this embodiment, one fluid port may be provided through which pressurized fluid flows into and out of the inner cavity of the hollow cavity, or at least two fluid ports may be provided, and the pressurized fluid flows into and out of the hollow cavity through different fluid ports. . It is easy to understand that the mold of this embodiment is provided with a resin injection port and a resin discharge port. In addition, when preparing tubular products, preferably, both ends of the hollow cavity 3 protrude from the upper mold 1 and the lower mold 2.

[0034] T...

Example Embodiment

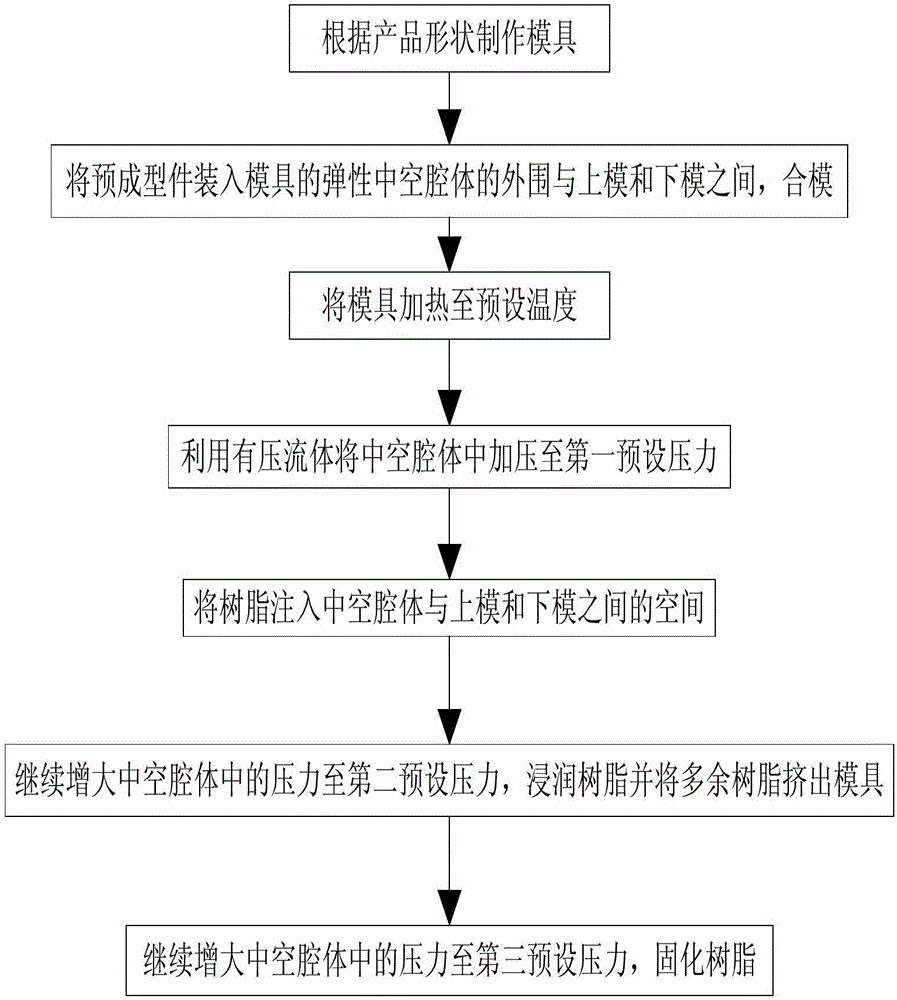

[0047] Embodiment two:

[0048] This embodiment provides an RTM molding process of a hollow composite product and a molding die used in the process. The structure of the forming mold is the same as that in the first embodiment, including an upper mold 1 and a lower mold 2, and a hollow cavity 3 arranged between the upper mold 1 and the lower mold 2. The hollow cavity 3 is provided with a pressure supply The fluid port where fluid flows in and out.

[0049] The RTM molding process of the hollow composite product in this embodiment is basically the same as that in the first embodiment, including steps A to G. The difference lies in: image 3 As shown, in step G of the RTM molding process of the hollow composite product in this embodiment, the pressure of the hollow cavity is continuously increased to a third preset pressure to cure the resin, and the third preset pressure is greater than the second preset pressure. In the curing stage, further increasing the pressure in the hollow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com