Composition for preparing demercuration adsorbent, demercuration adsorbent and preparation method of demercuration adsorbent

An adsorbent and composition technology, which is applied in the field of preparing the composition of the mercury removal adsorbent, can solve the problems of increasing the production cost of the mercury removal adsorbent, high requirements for continuous heat treatment, complicated impregnation process, etc. Effect of flue gas mercury removal ability, reduction of production cost and operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

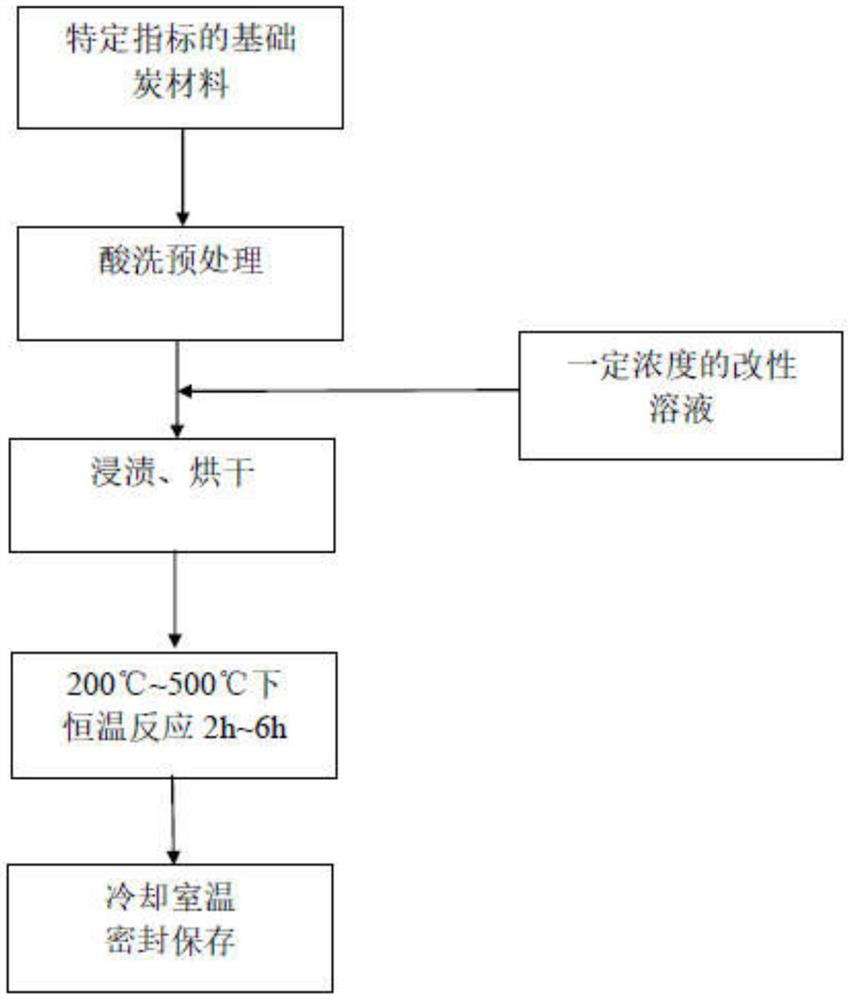

[0044] The preparation method of the modified mercury-removing adsorbent provided by the impregnation method of the present invention is to use the pretreated columnar large particle carbon material as the raw material, add a certain proportion of modifier, and modify by equal-volume impregnation, and finally Prepared by heat treatment process. Such as figure 1 As shown, it specifically includes the following steps:

[0045] Step 1: Prepare the pretreated carbon materials with preset indicators and modifiers of preset varieties according to the requirements of impregnation modification; specifically, the carbon materials are various woody activated carbons, coal-based activated carbons, coal-based activated carbons Activated coke and regenerated activated carbon / activated coke, etc.; the preset indicators are particle size 2mm-10mm, specific surface area 300m 2 / g-600m 2 / g, water capacity 30%-60%; the pretreatment is to immerse the carbon material in a 50%-60% hydrochloric...

Embodiment 1

[0054] First, the selected coal-based columnar granular activated coke has a particle size of 9mm and a specific surface area of 350m 2 / g, water capacity 40%, pickled by hydrochloric acid, washed to neutral, dried, then vibrated under vibrating sieve machine for 1min to remove excess carbon powder, set aside. Select hydrogen peroxide as modifier, weigh 100 grams of pretreated carbon material in proportion, measure 40 grams of hydrogen peroxide with a mass fraction of 30% as modifier solution, and the mass ratio of carbon material to modifier is 100:12. Put the carbon material in the hydrogen peroxide solution and let it soak for 24 hours. After impregnation, put it in an oven at 105°C and dry for 24 hours.

[0055] Put the dried impregnated carbon material into a tubular rotary furnace, and set the relevant experimental parameters for heat treatment. In this example, set the heating rate to 5°C / min, and keep it at the final reaction temperature of 450°C for 3 hours, and t...

Embodiment 2

[0058] First, the selected coal-based columnar granular activated coke has a particle size of 9mm and a specific surface area of 350m 2 / g, water capacity 40%, pickled by hydrochloric acid, washed to neutral, dried, then vibrated under vibrating sieve machine for 1min to remove excess carbon powder, set aside. Select ammonium chloride as the modifier, weigh 100 grams of pretreated carbon material in proportion, weigh 10 grams of ammonium chloride and dissolve it in 30 grams of water as the modifier solution, and the mass ratio of carbon material to modifier is 100 :10. Put the carbon material in the ammonium chloride solution and let it stand for 24 hours. After impregnation, put it in an oven at 105°C and dry for 24 hours.

[0059] Put the dried impregnated carbon material into a tubular rotary furnace, and set the experimental parameters related to heat treatment. In this example, set the heating rate to 5°C / min, and keep it at the final reaction temperature of 500°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com