Process for making aminoalcohol compounds

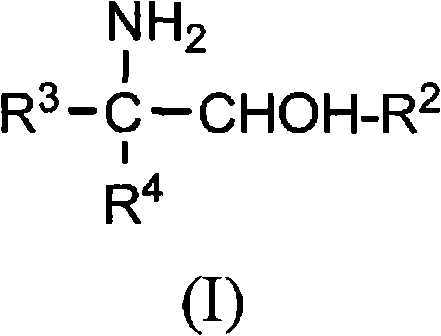

A compound, amino alcohol technology, applied in the field of manufacturing amino alcohol compounds, can solve problems such as by-products affecting the color and odor of target materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0041] Examples 1-8: 2-Amino-2-ethyl-1,3-propanediol

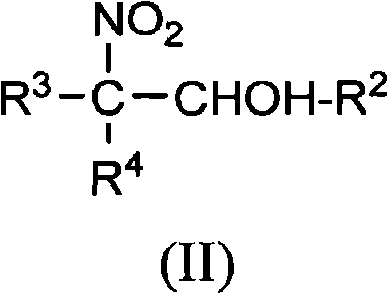

[0042] Examples 1-8 relate to 2-amino-2-ethyl-1,3-propanediol (AEPD), which can be prepared from 1-nitropropane and formaldehyde.

[0043] The analysis (characterization) methods used in the examples are as follows.

[0044] GC analysis. The effect of process variations on GC area % was monitored using an HP 5890 Series II Gas Chromatograph with a J&W DB-5 column of 30 m*0.25 mm*1.0 μm. Set the FID detector at 250°C and the injector at 180°C. The column temperature program is: 60°C for 4 minutes, ramp up to 220°C at a constant rate of 30°C / min, hold for 7 minutes, ramp up to 280°C at a constant rate of 20°C / min, and hold for 2 minutes. The injection volume was 1 μL, the split ratio was 100:1, and helium was used as the carrier gas.

[0045] HPLC analysis. The concentrations of the unwanted by-products of the condensation reaction, 2-nitrobutanol (2-NB) and 2-nitro-2-ethyl-1,3-propanediol (NEPD), were determined by HP...

Embodiment 1

[0058] Embodiment 1, this embodiment (control) uses 900.3g NEPD solution. No propylamine was added to the autoclave heel. 1169.3 g of autoclave filtrate was recovered.

Embodiment 2

[0059] Embodiment 2, this embodiment uses 900.1g NEPD solution. To the autoclave residue was added 5 mol.% propylamine (14.1 g). 1138.3 g of autoclave filtrate was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com