Repairing equipment used for butyl inner tube and using method

A butyl inner tube and equipment technology, applied in the field of rubber tire manufacturing, can solve the problems of cost waste, affecting the qualified rate of finished products, poor self-adhesiveness and mutual adhesion of butyl rubber, etc., to reduce production costs, simple structure, and ensure heating time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

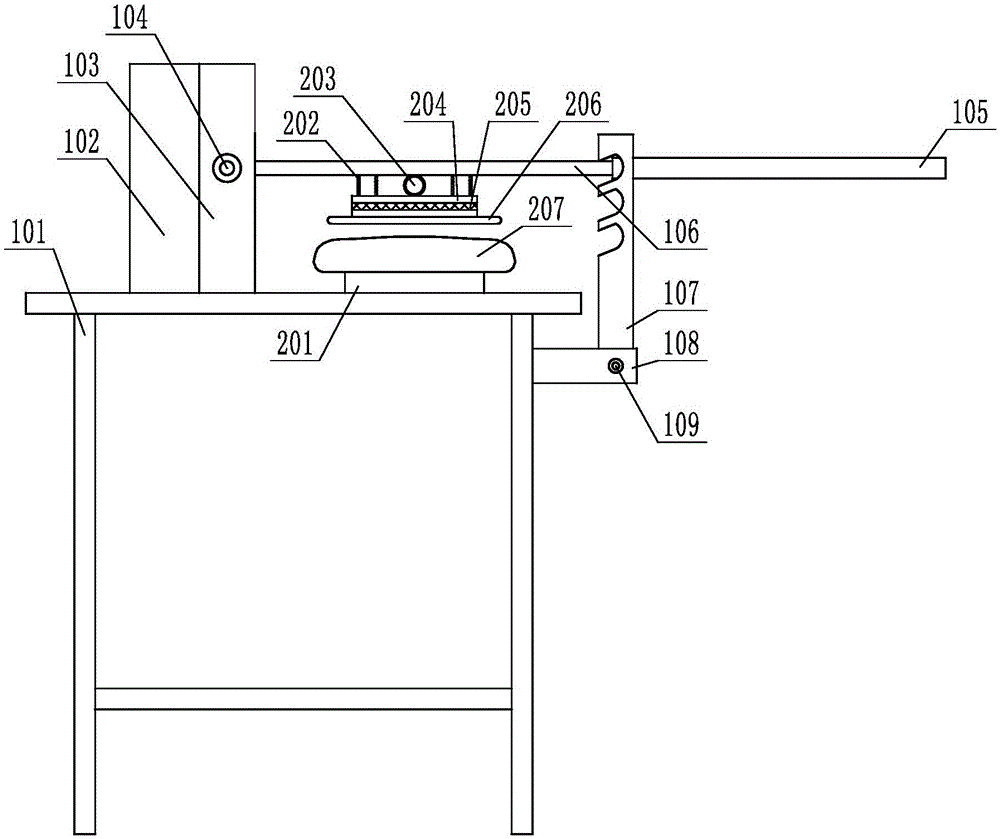

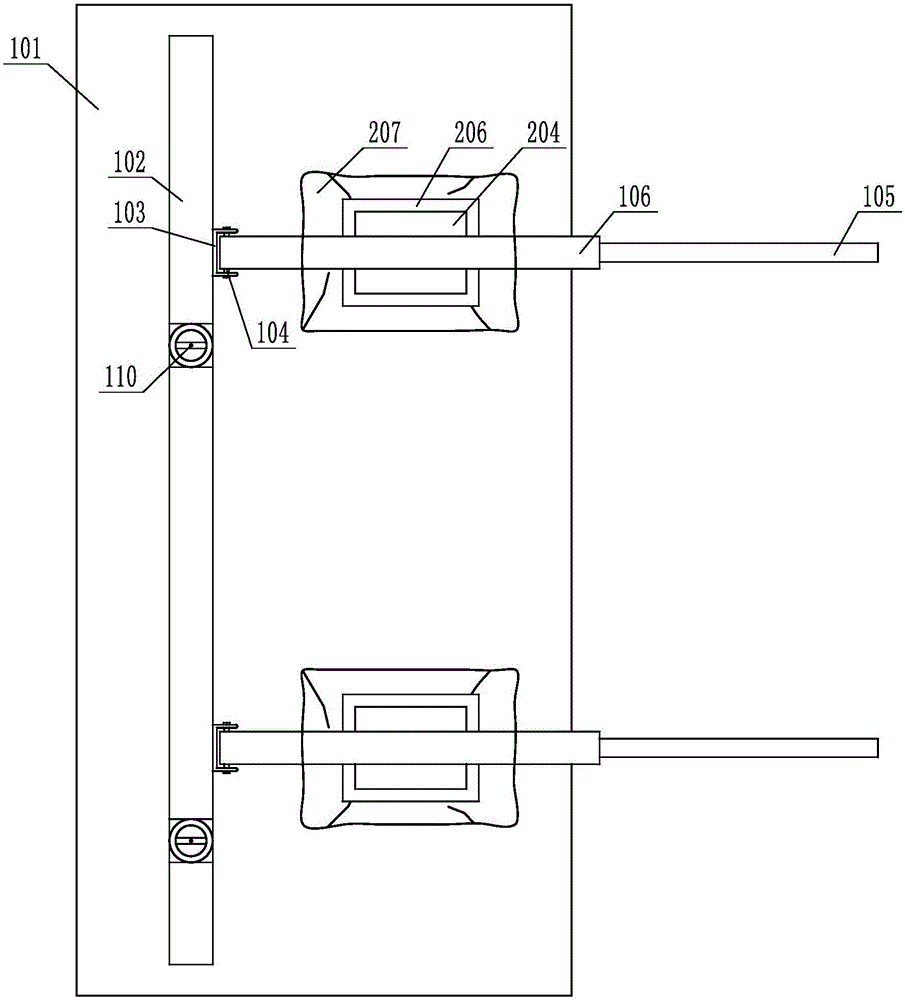

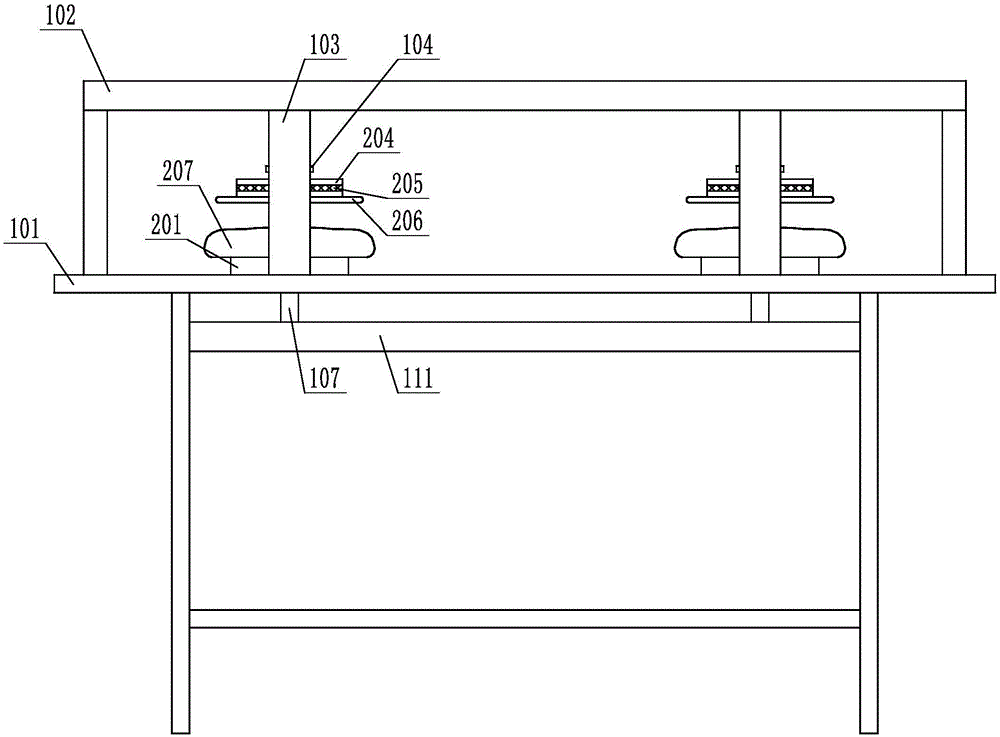

[0036] Such as Figure 1 to Figure 3 as shown,

[0037] The repairing equipment is mainly divided into two parts, the auxiliary mounting frame and the inner tube repairing part.

[0038] The auxiliary installation frame is built with the operating table case 101 as the main frame. The lower beam 111 is welded under the desktop of the operating table case 101. The lower cross beam 111 is preferentially welded between the two legs of the operating table case 101. The lower beam 111 is welded with a Two welded beams 108 , the clip bar 107 is installed at the end of the second welded beam 108 , and is hinged together through the second rotating shaft 109 . The movable end of the clamping bar 107 is provided with a plurality of clamping teeth, and the clamping teeth match the size of the handle 105 for clamping the handle 105 .

[0039] Further optimization, the handle 105 is provided with a plurality of grooves, which match the shape of the teeth at the movable end of the clip b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com