Cable reel assembly outbound distribution transmission line

A cable and transmission line technology, which is applied in the field of cable reel container outbound distribution transmission line, can solve the problems of large labor force, low distribution efficiency, and high labor intensity requirements, so as to reduce the number of labor, reduce the demand for personnel, and improve the supply. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

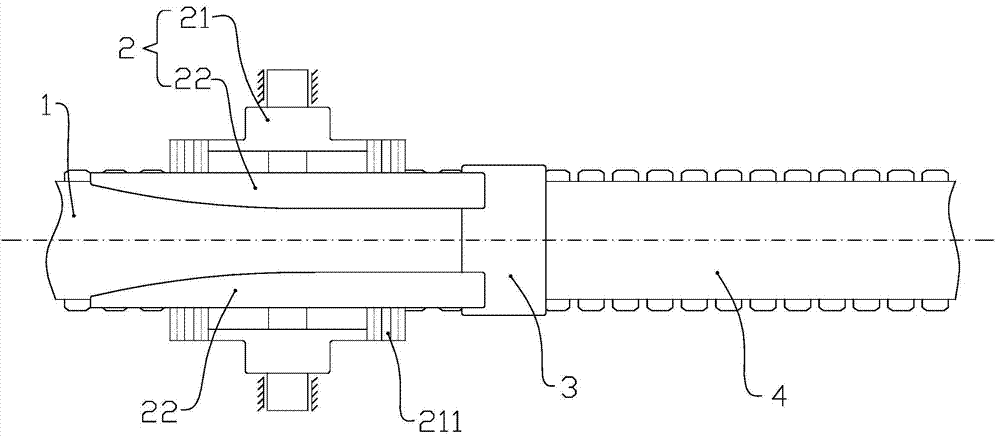

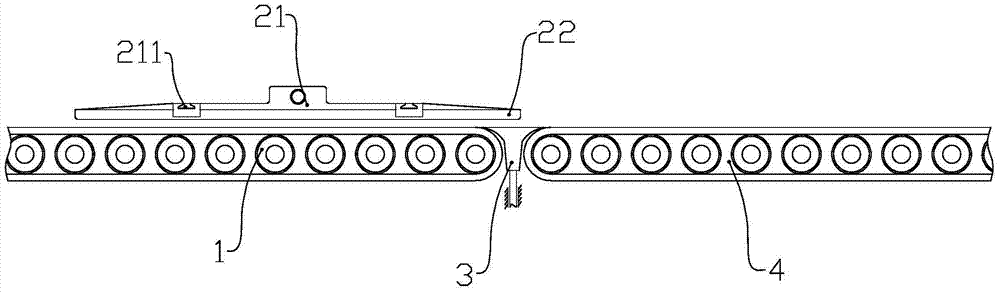

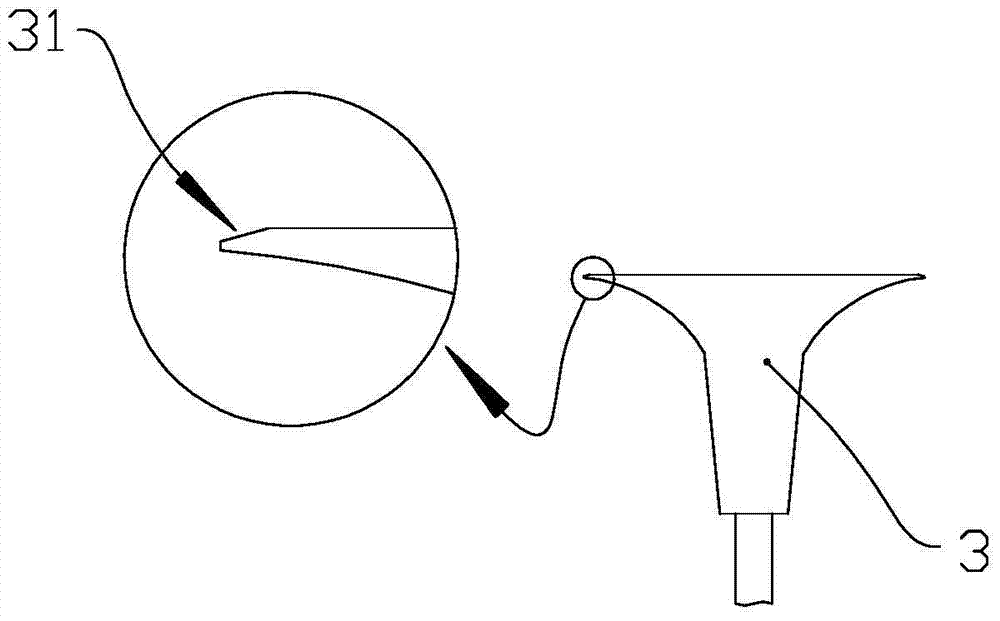

[0043] like Figure 1 to Figure 3The shown one cable reel container outbound distribution transmission line includes a first conveyor belt 1 , a guide unit 2 , a transition support 3 and a second conveyor belt 4 . The guide unit 2 includes two driving slides 21 and guide arms 22 corresponding to the driving slides 21 . The driving slide 21 is connected with the corresponding guide arm 22 and then placed on the front and rear sides of the first conveyor belt 1 respectively, and the lower end surface of the guide arm 22 is located at the upper end of the first conveyor belt 1, which is vertical. a certain distance apart. The driving slide 21 is matched with the frame through the guide rails 211 provided thereon. The two driving slides 21 are respectively connected with the driving device, and move linearly forward or backward relative to the frame under the action of the driving device, so as to control the size of the linear distance between the opposite end faces of the guid...

Embodiment approach 2

[0046] like Figure 4 to Figure 12 As shown, it is a further improvement of the above-mentioned cable reel bundled out warehouse distribution transmission line.

[0047] like Figure 4 5. As shown in FIG. 5, a chute unit 5 is provided at the right end of the second conveyor belt 4. The slideway unit 5 includes a first slideway 51 , a second slideway 52 and a bar frame 53 sequentially connected from left to right. The first slideway 51 is inclined downward from left to right, and the left end is placed below the right end of the second conveyor belt 4 . The second slideway 52 is also inclined downward from left to right, and the inclination angle of the second slideway relative to the horizontal plane (ie, θ in FIG. 6 ) 1 ) is greater than the inclination angle of the first slideway 51 relative to the horizontal plane. If the inclination angle of the second slideway 52 relative to the horizontal plane is set to 45 degrees, it is better to make the inclination angle of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com